Gypsum homogenizing chute

A chute, gypsum technology, applied in clinker production, cement production and other directions, can solve the problems of flow cut off and blockage in the material trough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

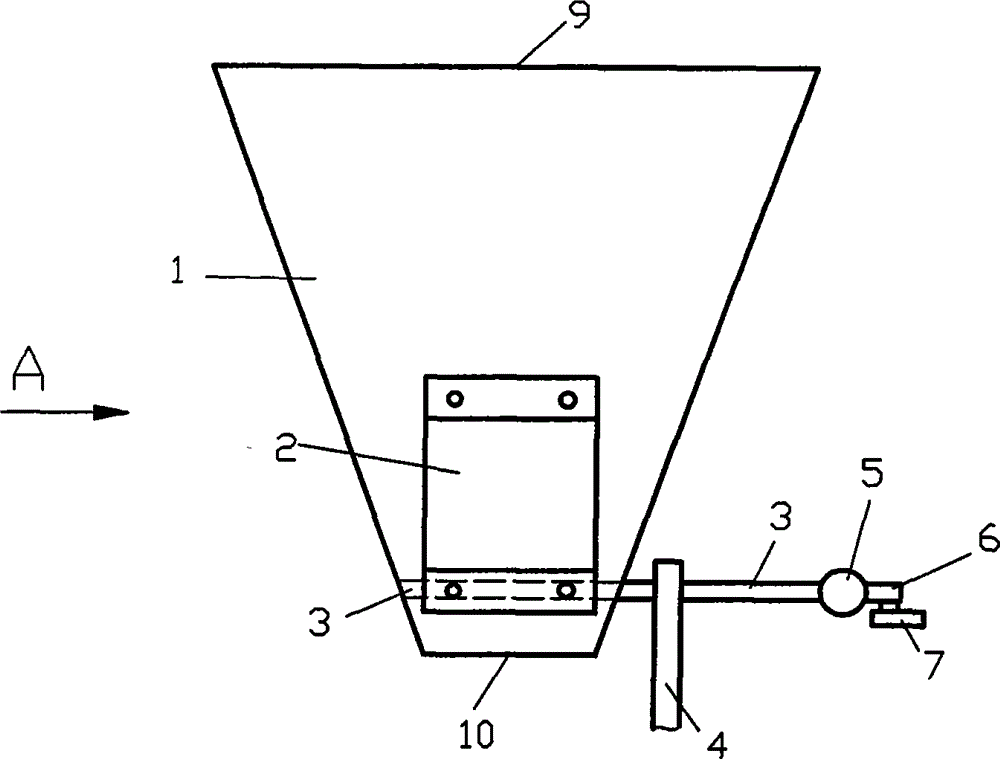

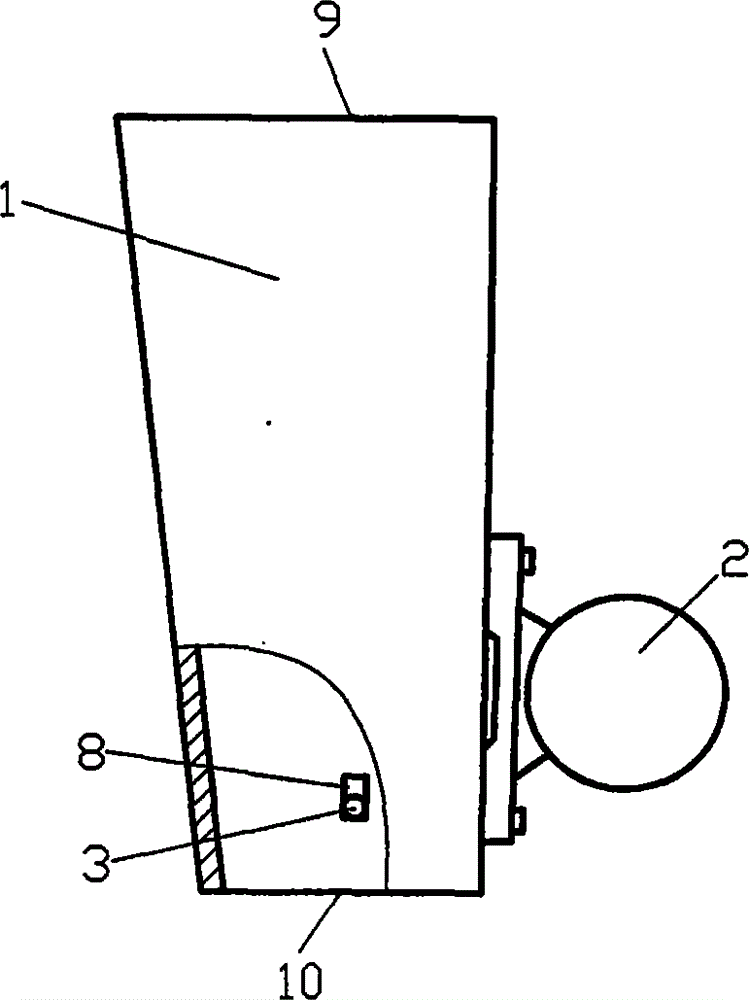

[0009] Such as figure 1 , figure 2 As shown, a gypsum homogenizing chute is composed of a chute body 1, a vibrating motor 2, an induction rod 3, a support rod 4, a counterweight hammer 5, a hammer head 6, a travel switch 7, a through hole 8, a feed port 9, an outlet It consists of a feed opening 10; it is characterized in that: the chute body 1 is an isosceles trapezoidal hollow structure composed of an upper and lower wall of an isosceles trapezoid and two waist walls, the upper end of the chute body 1 is a feed inlet 9, and the lower end is a discharge Port 10; on the outer wall of the chute body 1 on the top of the discharge port 10, a vibration motor 2 is fixed with bolts; the lower end of the waist wall of the chute body 1 is provided with a through hole 8, and one end of the induction rod 3 is used to pass through the through hole 8 reaches at least the central position in the cavity formed by the chute body 1; the other end of the induction rod 3 is welded with a coun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com