Hydraulic controllable metal material shearing device

A technology for shearing devices and metal materials, applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve the problems of being unable to stop or start at any time, unable to achieve continuous shearing, and increasing production costs, etc., to achieve The structure is simple, the operation is convenient, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

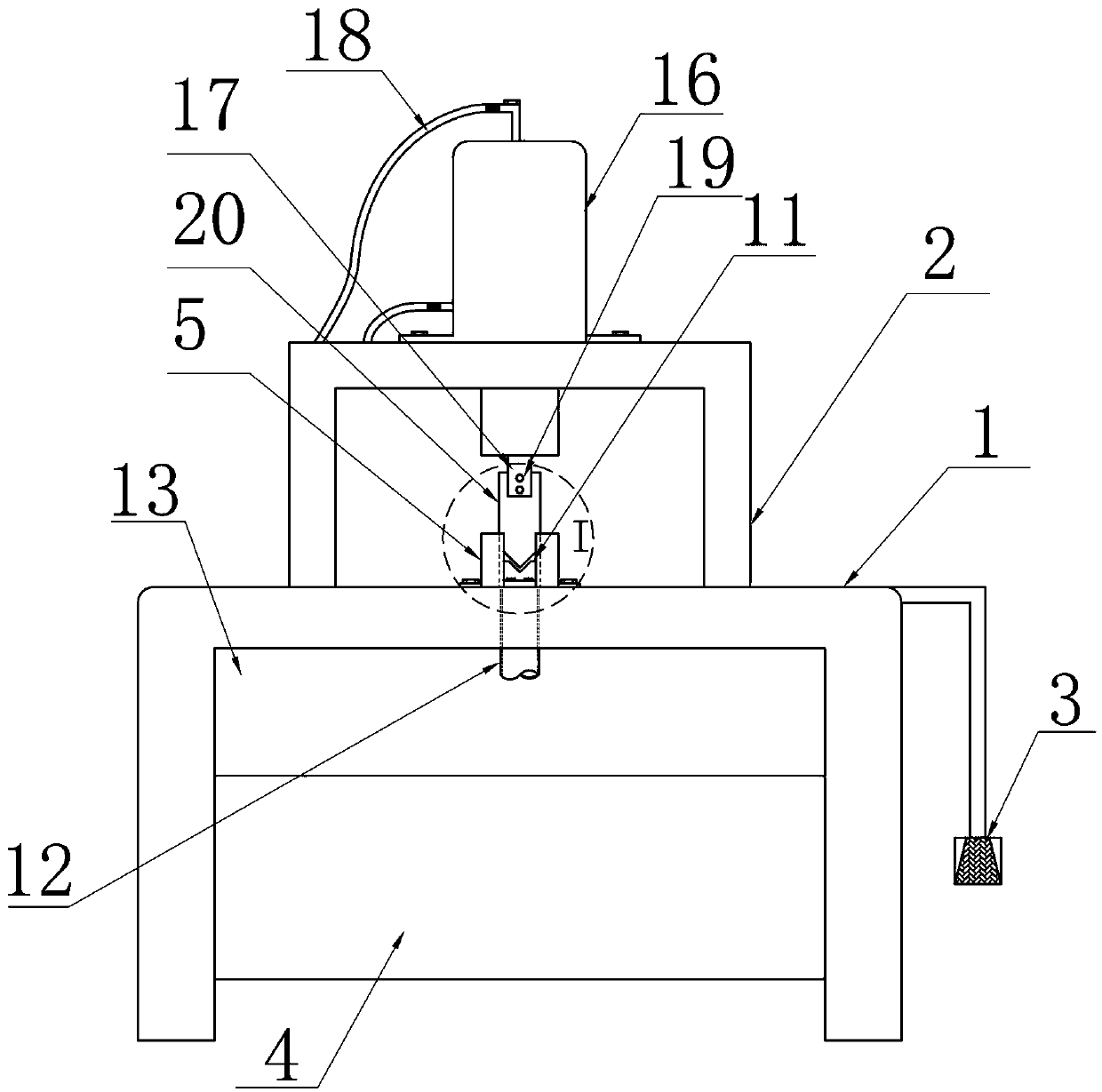

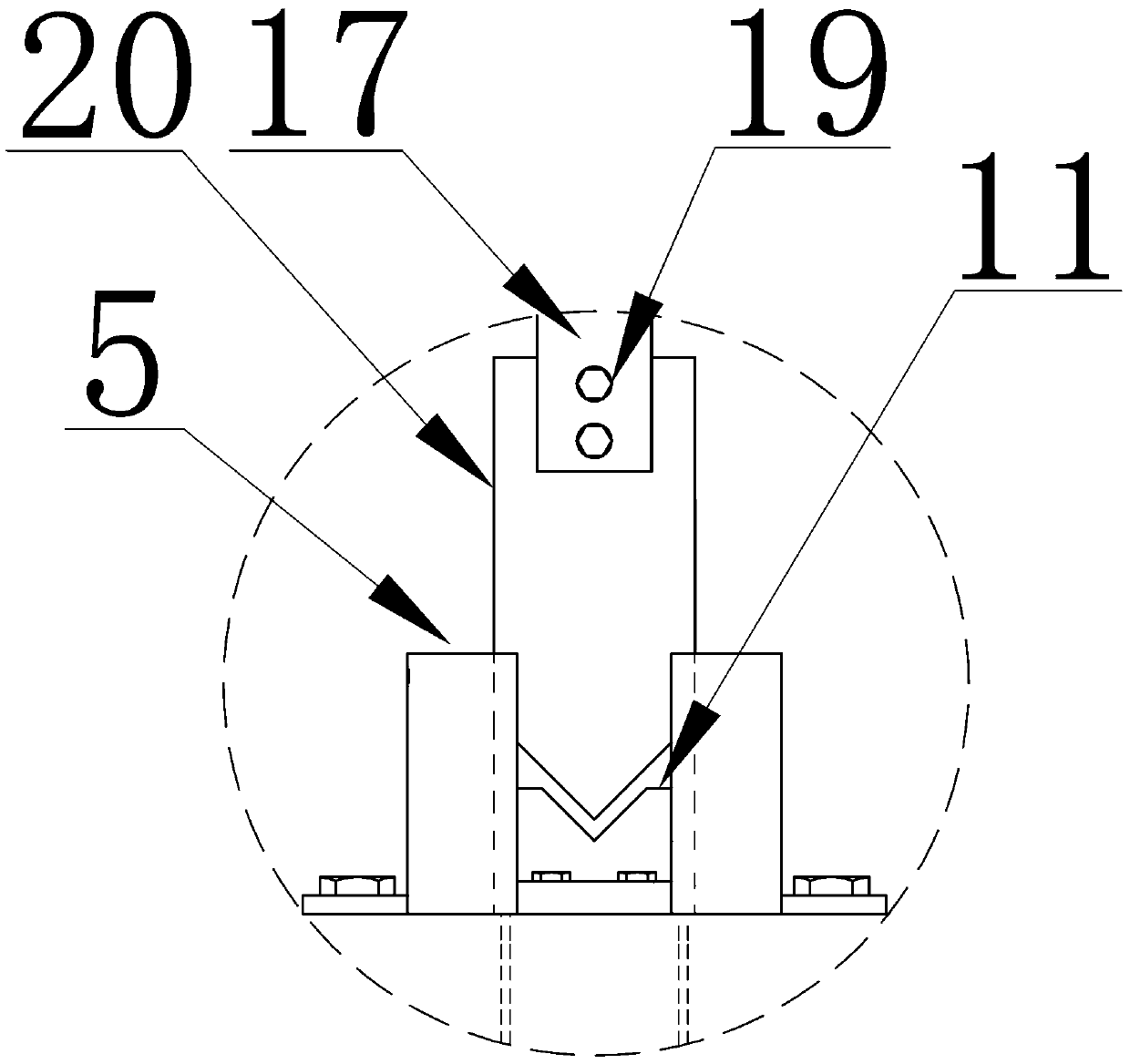

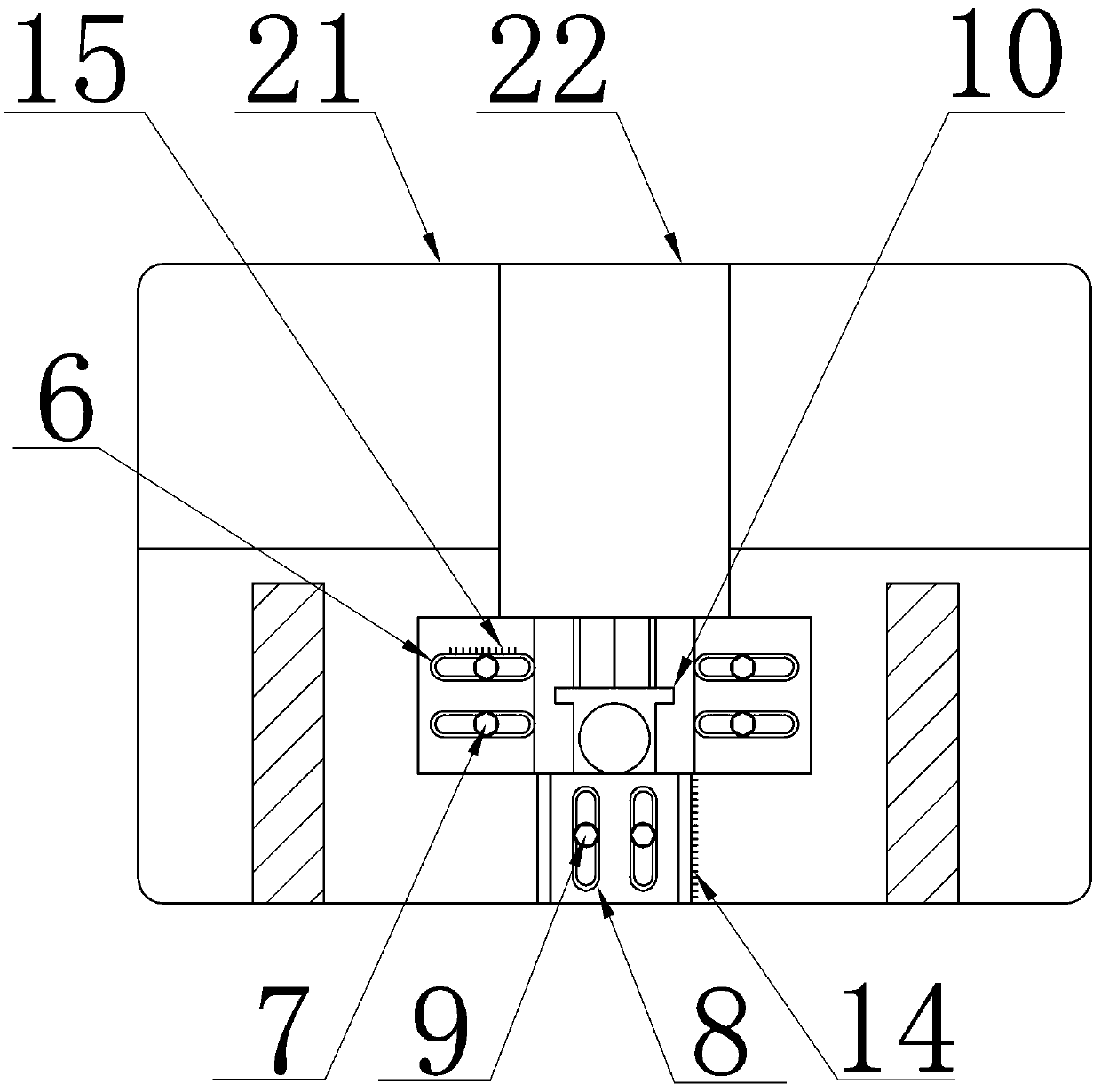

[0017] See figure 1 , a hydraulically controllable metal material shearing device, comprising a frame 1 and a hydraulic cylinder support 2, a hydraulic system switch 3 and a control box 4 are arranged on the frame 1, and a shearing device 5 is arranged on a platform at the upper end of the frame. The device 5 includes a width adjustment block, a length adjustment block, a shear knife limit groove 10 and a material chute 11 . The trough 11 is used to stably place the material to be sheared, and its shape corresponds to the shape of the material to be sheared. For example, the material to be sheared is an angle iron, and the shape of the trough is V-shaped. The width adjustment block and the length adjustment block are connected to the rack platform by fastening the width adjustment bolt 7 and the length adjustment bolt 9 in the width adjustment groove 6 and the length adjustment groove 8 provided, and the rack platform is provided with the width adjustment bolt 7 and the length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com