Composite electrorheological elastomer material of starch, transformer oil drop and silicone rubber

A technology of elastomer material and transformer oil, applied in the field of electrorheological elastomer material, can solve problems such as reducing the elasticity of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

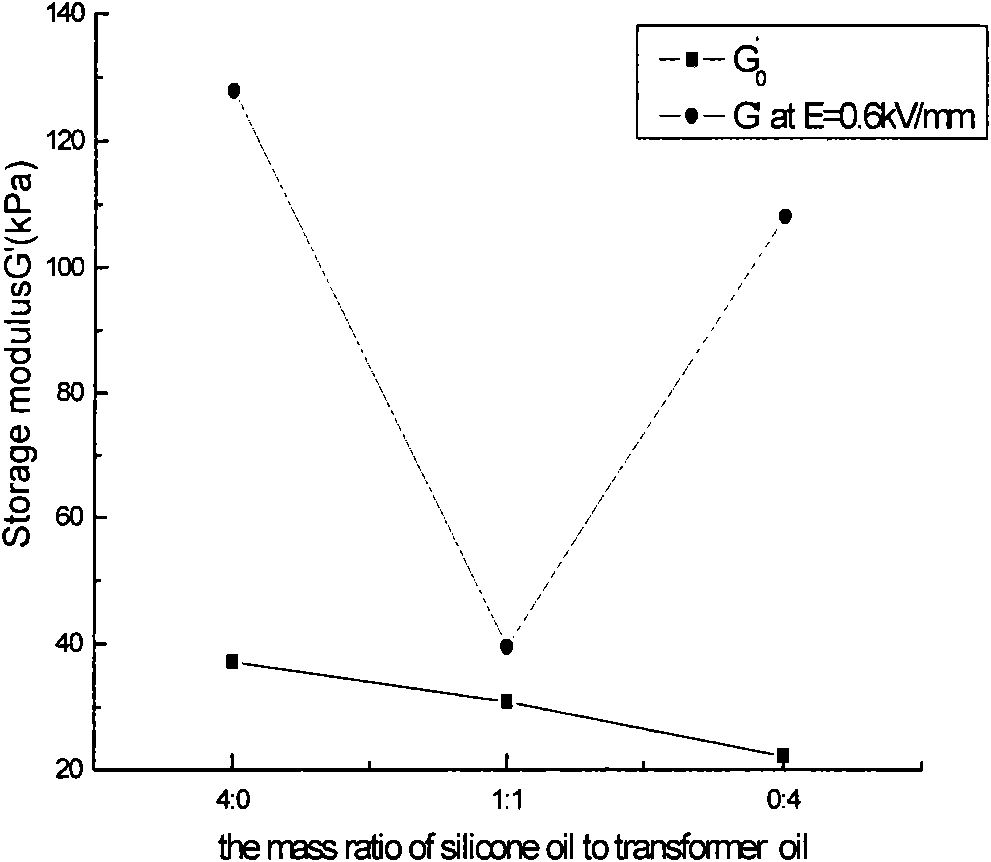

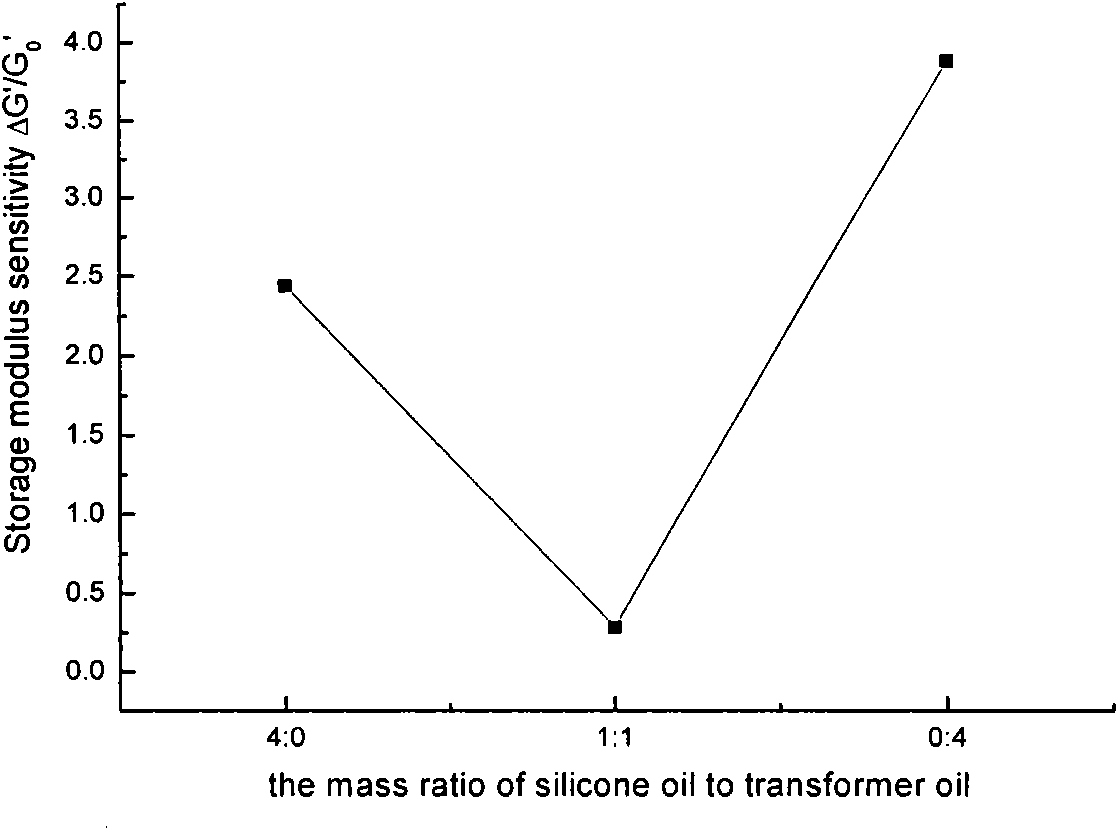

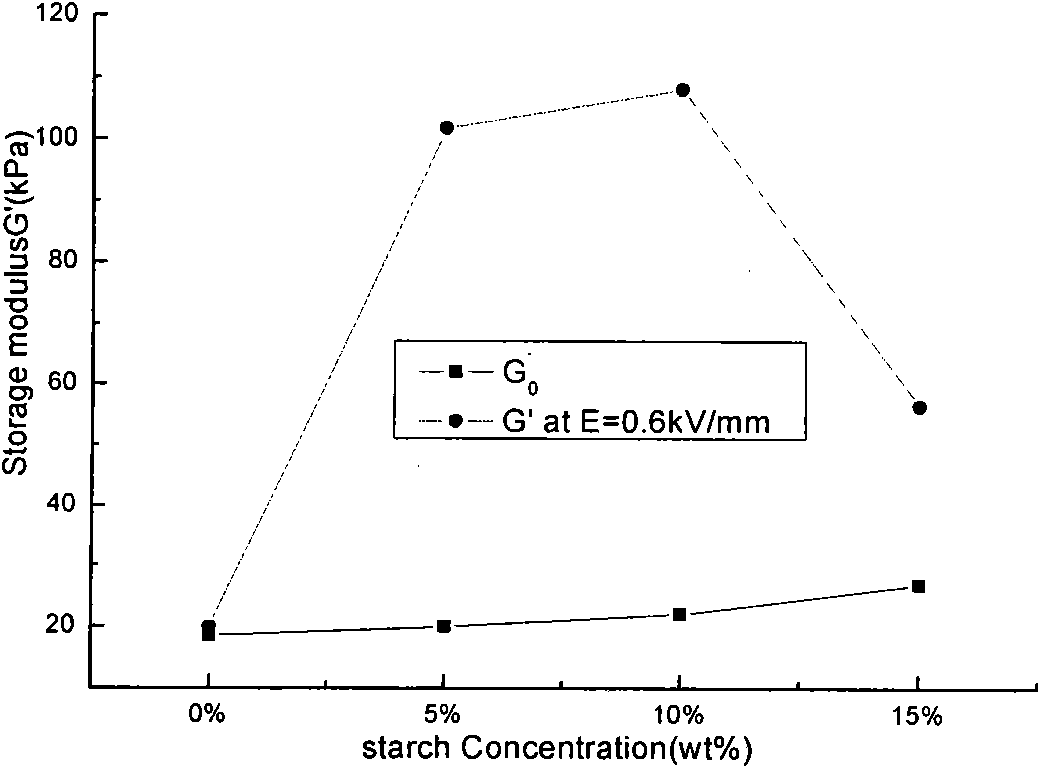

[0019] Put 0.824g of starch in 4g of silicone oil and stir magnetically for 30 minutes to disperse the starch evenly into the transformer oil to prepare a certain ratio of electrorheological fluid; add 4g of 107 silicone rubber to the above electrorheological fluid under stirring conditions, Until the dispersion is uniform; add an appropriate amount of curing agent to the system, and continue to stir until the curing agent is evenly mixed; quickly transfer it to a conductive glass box (40mm×20mm×5mm) and let it stand, in the absence or presence of an external DC electric field ( 0.6kV / mm), wherein the electric field is applied until the end of the curing process. In this way, two types of composite electroelastomers with a starch content of 10wt% and silicone oil:transformer oil=4:0 are prepared. Its storage modulus and relative storage modulus changes are shown in figure 1 , figure 2 .

Embodiment 2

[0021] Put 0.824g of starch in 2g of transformer oil, and stir magnetically for 30 minutes, so that the starch is evenly dispersed in the transformer oil, and a certain proportion of electrorheological fluid is prepared; put 2g of silicone oil in 4g of 107 silicone rubber, and use a constant temperature magnetic stirrer Stir to make it evenly mixed; add the above electrorheological fluid to the rubber mixture under stirring until uniformly dispersed; add an appropriate amount of curing agent to the system, and continue stirring until the curing agent is evenly mixed; quickly transfer it to Stand still in the conductive glass box (40mm * 20mm * 5mm), solidify under the action of no or with an external DC electric field (0.6kV / mm), wherein the electric field is added until the curing process ends, so that the starch content is 10wt%. Two types of composite electroelastomers with silicone oil:transformer oil=1:1. Its storage modulus and relative storage modulus changes are shown ...

Embodiment 3

[0023] Put 0.824g of starch in 4g of transformer oil and stir it magnetically for 30 minutes to disperse the starch evenly in the transformer oil to prepare a certain ratio of electrorheological fluid; add 4g of 107 silicone rubber to the above electrorheological fluid under stirring conditions , until it is uniformly dispersed; add an appropriate amount of curing agent to the system, and continue to stir until the curing agent is evenly mixed; quickly transfer it to a conductive glass box (40mm×20mm×5mm) and let it stand, in the absence or presence of an external DC electric field (0.6kV / mm) is solidified, and an electric field is applied until the curing process is completed. In this way, two types of composite electroelastomers with a starch content of 10wt% and silicone oil:transformer oil=0:4 are prepared. Its storage modulus and relative storage modulus changes are shown in figure 1 , figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com