Method for manufacturing cherry brandy

A technology for cherry brandy and a production method, which is applied in biochemical equipment and methods, wine preparation, alcoholic beverage preparation, etc., can solve the problems of irritating aroma, weak wine body, lack of coordination, etc., and achieves rich and mellow aroma and aftertaste. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

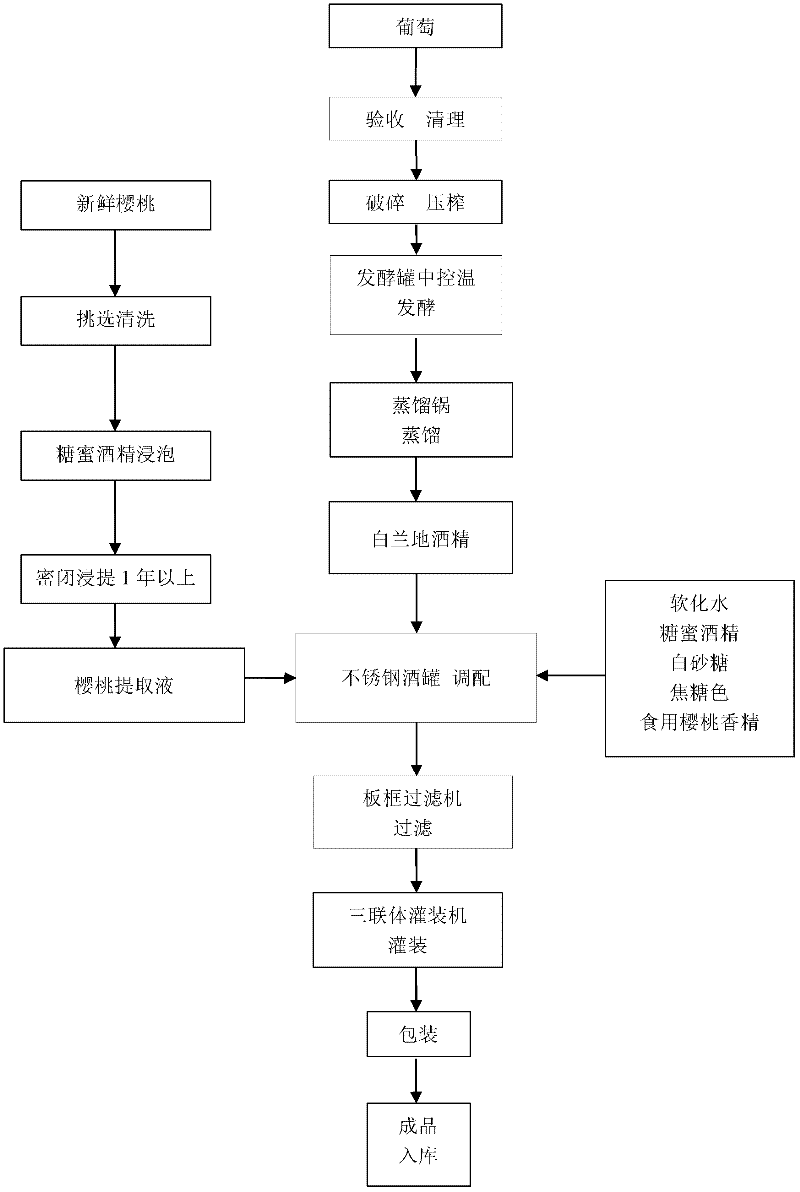

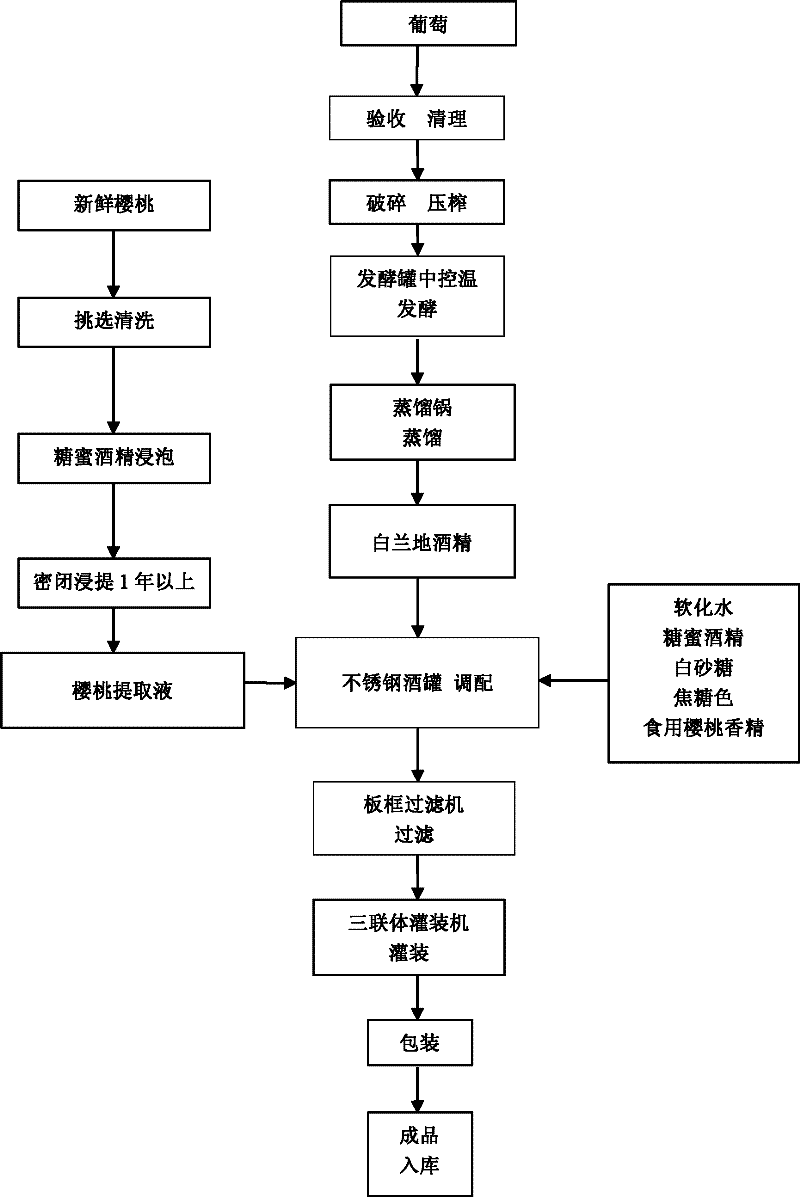

[0022] The production method of cherry brandy of the present invention comprises the steps:

[0023] (1) Preparation of cherry extract: ①Clean the selected fresh cherries; ②Pour it into molasses alcohol for soaking, and mix 1 part of cherries with 2.5 parts of 95% molasses alcohol according to the weight ratio; cherry extract;

[0024] (2) Preparation of brandy alcohol: ① breaking and squeezing grapes that meet the requirements of the winemaking process; ② fermenting in a fermenter with controlled temperature at 15-20° C. for 18-30 days. ③ After the fermentation is over, use a still pot to distill to obtain brandy alcohol;

[0025] (3) Cherry brandy deployment: Proportion by weight, 10 parts of cherry extract, 27 parts of brandy alcohol, 29.9 parts of white granulated sugar, 0.8 part of caramel color, 0.3 part of edible cherry essence, 12 parts of molasses alcohol, 20 parts of demineralized water;

[0026] (4) The mixed solution is prepared in the tank and stabilized for mor...

Embodiment 2

[0029] The cherry brandy of the present invention comprises 12 parts of cherry extract by weight, 27 parts of brandy alcohol, 28 parts of white granulated sugar, 1.2 parts of caramel color, 0.2 part of edible cherry essence, 11 parts of molasses alcohol and 20.6 parts of demineralized water.

[0030] Its production method is with embodiment 1.

Embodiment 3

[0032] The cherry brandy of the present invention comprises 11 parts of cherry extract by weight, 29 parts of brandy alcohol, 29 parts of white granulated sugar, 1.0 part of caramel color, 0.2 part of edible cherry essence, 10 parts of molasses alcohol and 20.8 parts of demineralized water.

[0033] Its production method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com