Processing method of oriental tobacco leaves

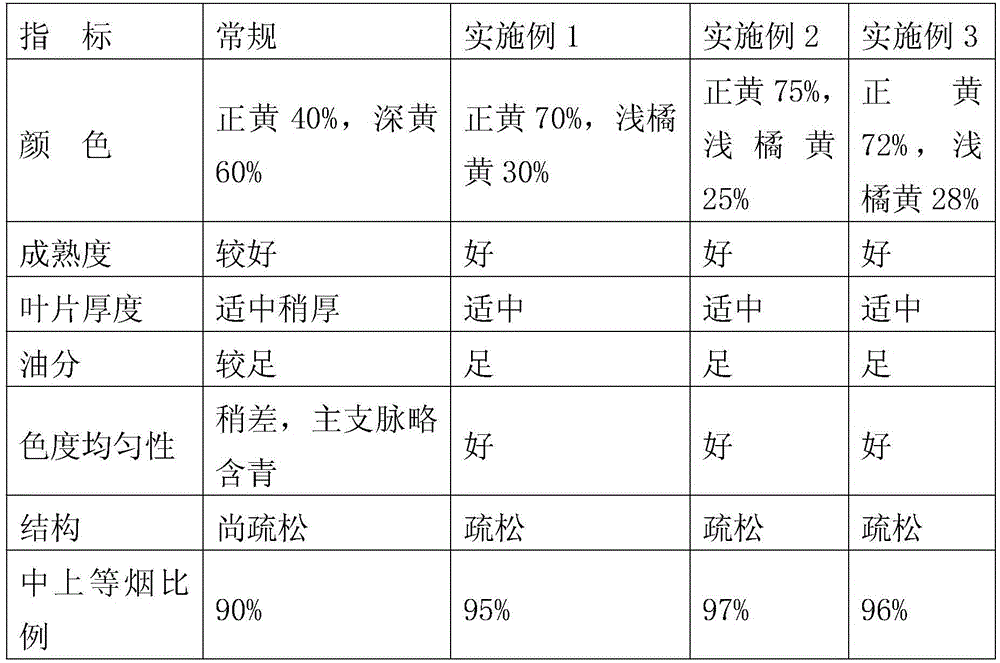

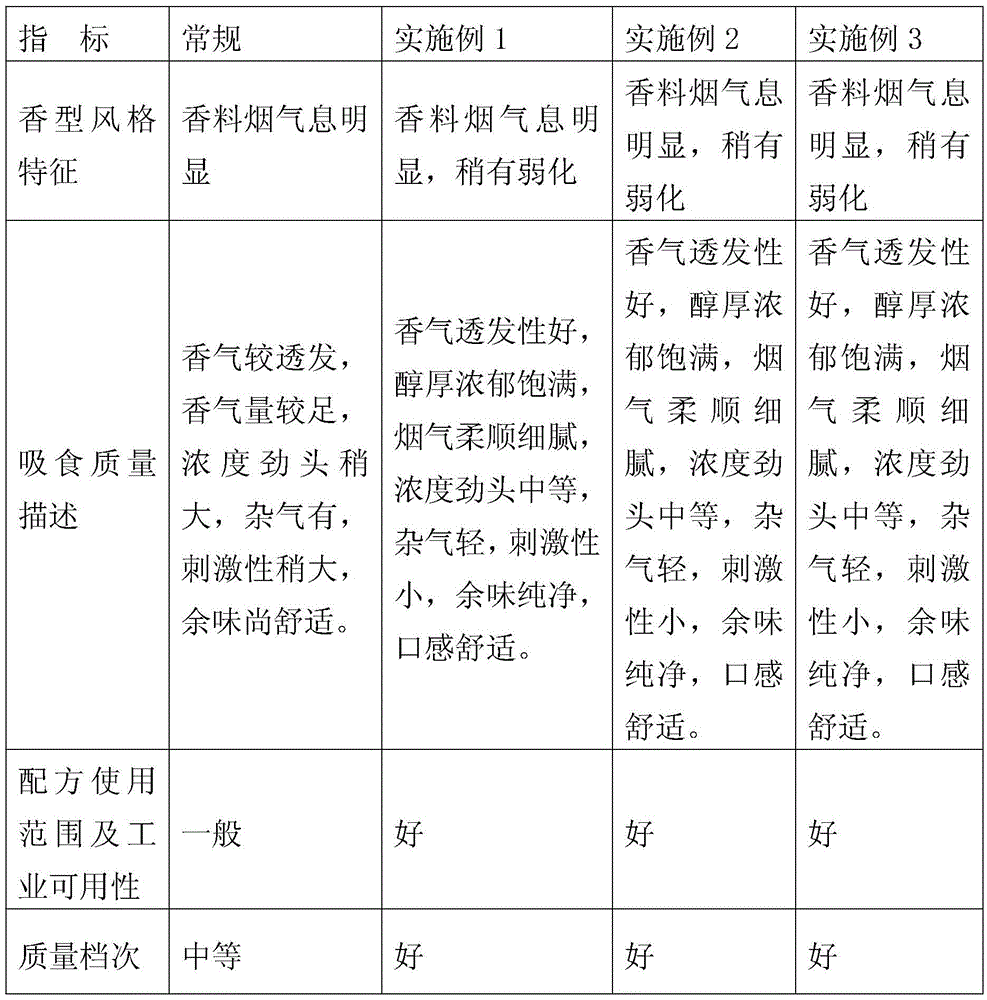

A processing method and technology for oriental tobacco, which are applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of high total nitrogen and protein content of chemical components, affecting industrial usability and use value, poor gloss and elasticity, etc. The use value is improved, the usability is remarkable, and the effect of the green and turbulent gas is light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Taking the mature tobacco leaves in the middle part of oriental tobacco as an example, the processing method of oriental tobacco leaves of the present invention has the following steps:

[0024] The first step: the mature fresh tobacco leaves are piled up and then ripened.

[0025] The ripe fresh tobacco leaves of oriental tobacco picked back are about 400 pieces, sorted and stacked according to leaf size, blue and yellow, and degree of pest damage, and then covered with plastic film in piles, and piled up for about 6 hours, and the film is lifted. When more than 95% of the leaves reach 30% yellow, they can be braided and hung in a drying room for airing. Among them, tobacco leaf stringing is to thread the same type of tobacco leaves into a rope, that is, when threading, the leaf backs face the leaf backs, and each bundle has 2 pieces. Each rope requires the same color, same quality, and same size.

[0026] The second step: dry in the shade and wither and...

Embodiment 2

[0037] The first step: the mature fresh tobacco leaves are piled up and then ripened.

[0038] The ripe fresh tobacco leaves of oriental tobacco picked back are about 300 pieces, sorted and stacked according to leaf size, blue and yellow, and degree of pest damage, etc., and then covered with plastic film in piles, and piled up for about 8 hours. When more than 95% of the leaves reach 40% yellow, they can be braided and hung in a drying room for airing. Among them, tobacco leaf stringing is to thread the same type of tobacco leaves into a rope, that is, when threading, the leaf backs face the leaf backs, and each bundle has 2 pieces. Each rope requires the same color, same quality, and same size.

[0039] The second step: dry in the shade and wither and turn yellow.

[0040] The bunches of tobacco leaves are hung in the drying room for drying, requiring a temperature of 30°C and a relative humidity of 80%, and the color of more than 95% of the leaves reaches 9 to 10 percent y...

Embodiment 3

[0050] The first step: the mature fresh tobacco leaves are piled up and then ripened.

[0051] The mature fresh tobacco leaves of oriental tobacco picked back are divided into about 500 pieces, classified and stacked according to leaf size, blue and yellow, and degree of pest damage, etc., and then covered with plastic film in separate piles, and the pile is covered for about 7 hours. When more than 95% of the leaves reach 30% yellow, they can be braided and hung in a drying room for airing. Among them, tobacco leaf stringing is to thread the same type of tobacco leaves into a rope, that is, when threading, the leaf backs face the leaf backs, and each bundle has 2 pieces. Each rope requires the same color, same quality, and same size.

[0052] The second step: dry in the shade and wither and turn yellow.

[0053] The bunches of tobacco leaves are hung in the drying room for drying, requiring a temperature of 25°C and a relative humidity of 75%, and the color of more than 95% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com