Preparation process for wine yeast special for large jar of fermented yellow wine

A preparation process, a technology for liquor, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of weak taste, rancidity, no obvious improvement in taste, etc., and achieve excellent fermentation performance, pure aroma, and mellow taste. rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

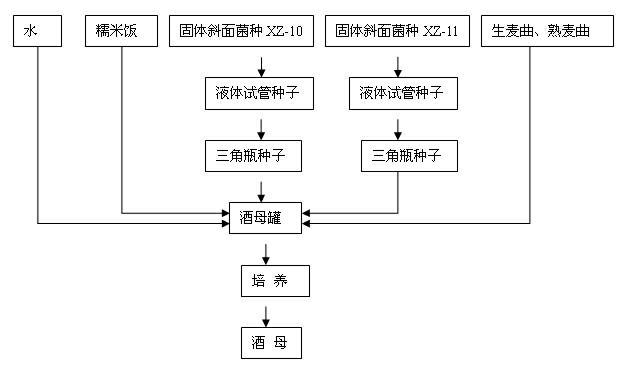

[0023] Embodiment 1: as figure 1 As shown, the preparation process of the special distiller's mother for fermented rice wine in large tanks is as follows: (1) Rice soaking: the water surface is 6-10 cm higher than the rice surface, and the rice is soaked at room temperature 20°C for 6 days. Drain the soaked rice; ⑵ Steamed rice: the steamed rice is required to be cooked but not mushy, and there is no heart in it; ⑶ Canning: The formula is based on 100 kg of glutinous rice, add 150 kg of water, 14 kg of raw wheat koji, and 100 kg of cooked wheat koji. 2 kg of koji, 3500 ml of yeast liquid in the triangular flask, of which the yeast liquid in the triangular flask is prepared from XZ-10 yeast liquid and XZ-11 yeast liquid with a weight ratio of 1:1; when falling into the tank, put clean water in the tank first and 2 / 3 of the yeast liquid in the triangular flask, stir well, then put in the cooled glutinous rice, raw wheat koji, cooked wheat koji and the remaining yeast liquid in ...

Embodiment 2

[0024] Embodiment 2: as figure 1 As shown, the preparation process of the special distiller's mother for fermented yellow rice wine in a large tank is as follows: (1) Rice soaking: the water surface is 6-10 cm higher than the rice surface, and the rice is soaked at 23°C for 5 days. Drain the soaked rice; ⑵ Steamed rice: the steamed rice is required to be cooked but not mushy, and there is no raw heart in it; ⑶ Canning: the formula is based on 100 kg of glutinous rice, add 140 kg of water, 13 kg of raw wheat koji, cooked wheat koji 3 kg of koji, 4000 ml of yeast liquid in the triangular flask, of which the yeast liquid in the triangular flask is prepared from XZ-10 yeast liquid and XZ-11 yeast liquid with a weight ratio of 2:1; when falling into the tank, put clean water in the tank first and 2 / 3 of the yeast liquid in the triangular flask, stir well, then put in the cooled glutinous rice, raw wheat koji, cooked wheat koji and the remaining yeast liquid in the triangular flask...

Embodiment 3

[0025] Embodiment 3: as figure 1 As shown, the preparation process of the special distiller's mother for fermenting yellow rice wine in a large tank is as follows: (1) Rice soaking: the water surface is 6-10 cm higher than the rice surface, and the rice is soaked at 22°C for 5 days. Drain the soaked rice; ⑵ Steamed rice: the steamed rice is required to be cooked but not mushy, and there is no heart in it; ⑶ Canning: the formula is based on 100 kg of glutinous rice, add 145 kg of water, 12 kg of raw wheat koji, and 12 kg of cooked wheat koji. 3 kg of koji, 3000 ml of yeast liquid in the triangular flask, of which the yeast liquid in the triangular flask is prepared from XZ-10 yeast liquid and XZ-11 yeast liquid with a weight ratio of 0.5:1; when falling into the tank, put clean water in the tank first and 2 / 3 of the yeast liquid in the triangular flask, stir well, then put in the cooled glutinous rice, raw wheat koji, cooked wheat koji and the remaining yeast liquid in the tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com