RH vacuum refining method of ultra-low carbon stainless steel

A vacuum refining and stainless steel technology, applied in the refining field of ultra-low carbon steel, can solve the problem that the decarburization advantage of RH vacuum device cannot be effectively expanded, and achieve the effect of rapid denitrification and decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

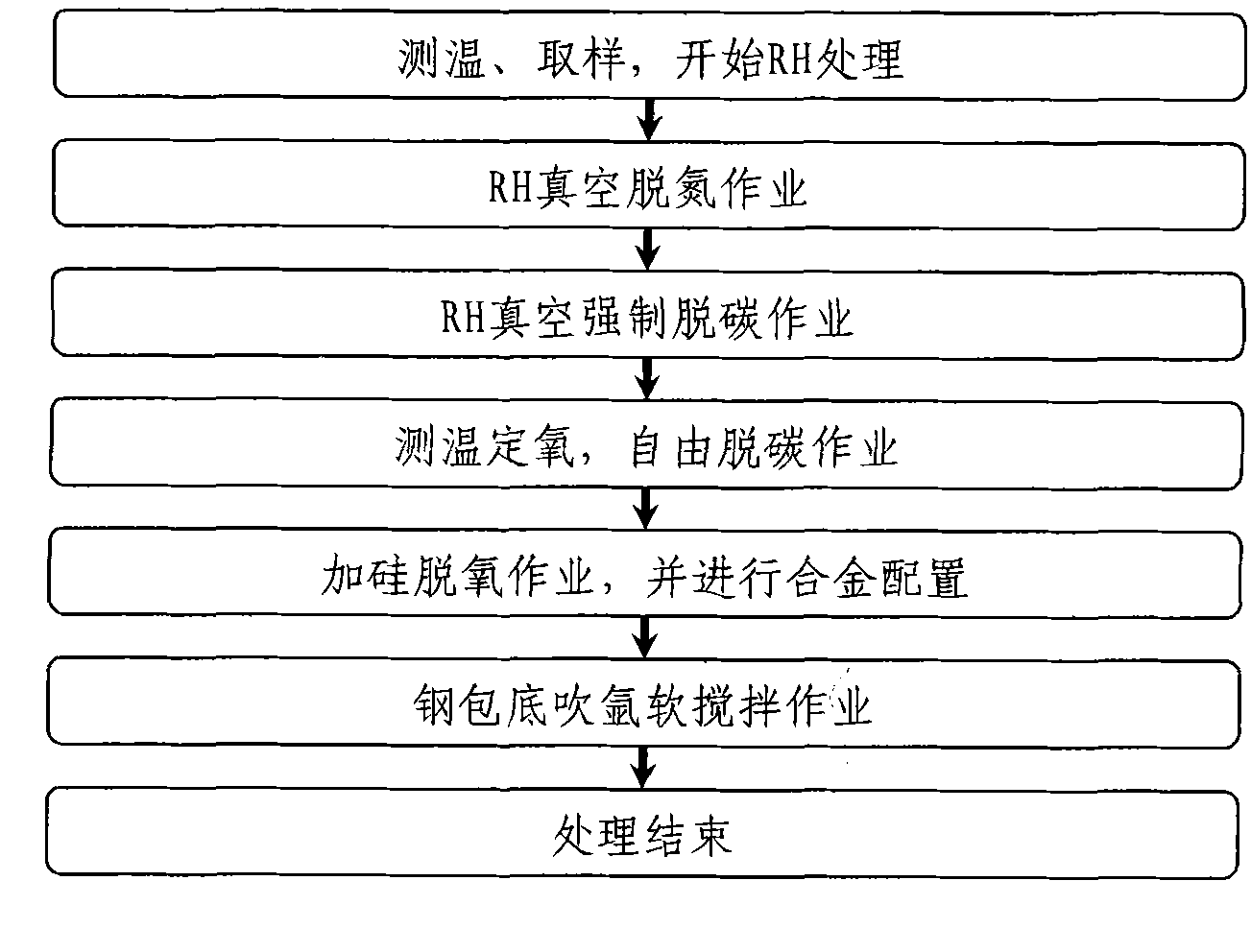

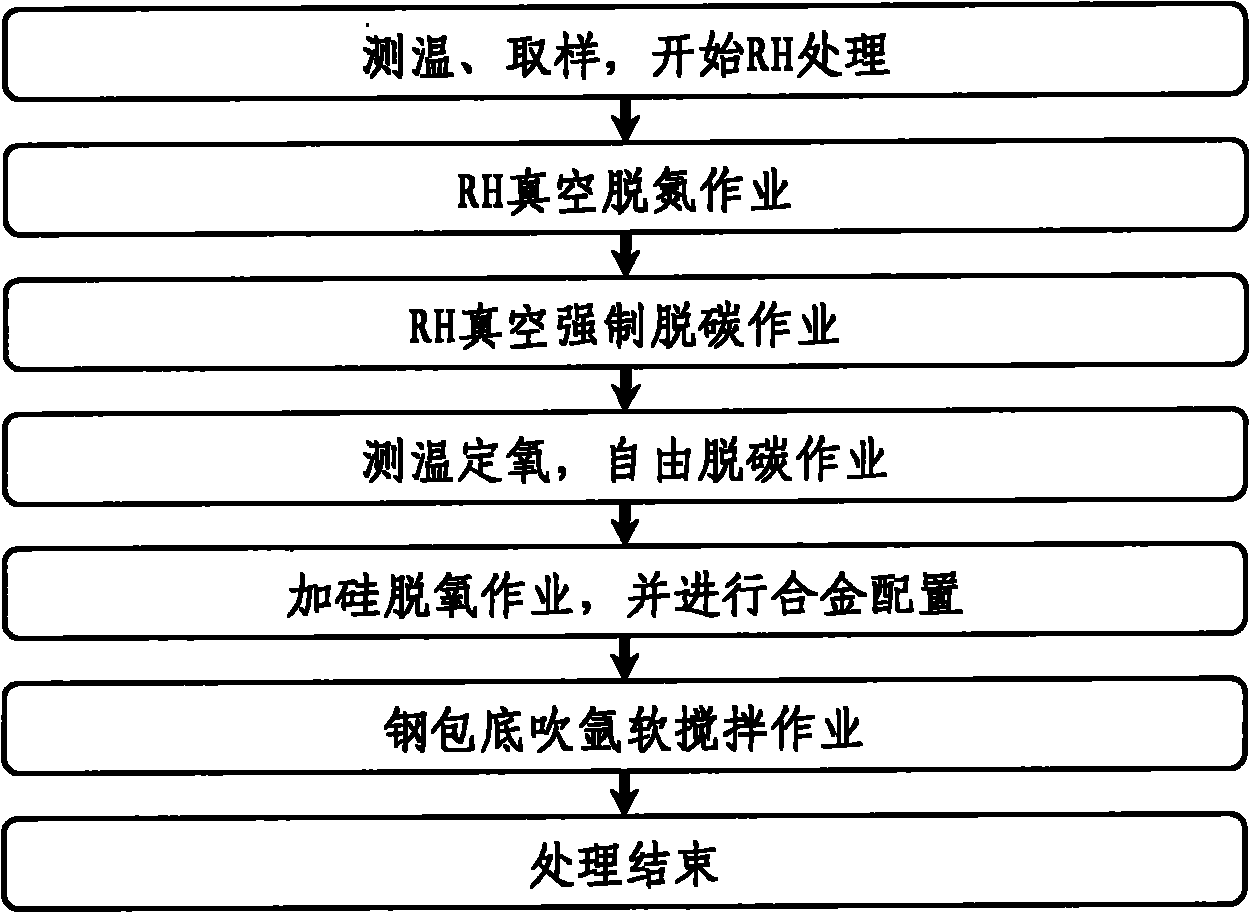

Method used

Image

Examples

Embodiment 1

[0035] Example 1, refining ferritic stainless steel with a carbon content of 0.03% (300ppm) and a nitrogen content of less than 150ppm.

[0036] A. The temperature of molten steel in the ladle is detected to be 1570°C; while the initial carbon content in the molten steel is 0.10%, and the initial nitrogen content of the treatment is 800ppm;

[0037] B. Keep the RH vacuum degree at 6.0kpa, and carry out the preliminary denitrification operation of RH vacuum. The vacuum time is maintained at 5 minutes. At this time, the lifting gas flow rate is controlled at 1200Nl / min;

[0038] C. After the end of the denitrification process, keep the RH vacuum at 6.0kpa and enter the forced decarburization process: control the oxygen flow rate of the top lance at 1200Nm 3 / h, properly adjust the lifting gas flow rate, control the lifting gas flow rate from 1200Nl / min to 1800Nl / min, in order to increase the liquid steel ring flow rate, thereby increasing the decarburization speed, and control t...

Embodiment 2

[0043] Example 2, refining ferritic stainless steel with a carbon content of 0.01% (100 ppm) and a nitrogen content of less than 100 ppm.

[0044] A. The temperature of molten steel in the detection ladle is 1595°C; while the initial carbon content in the molten steel is 0.10%, and the initial nitrogen content of the treatment is 800ppm;

[0045] B. Keep the RH vacuum degree at 5.5kpa, and carry out the preliminary denitrification operation of RH vacuum. The vacuum time is maintained at 10 minutes, and the lifting gas flow rate is controlled at 1400Nl / min at this time;

[0046] C. After the end of the denitrification process, keep the RH vacuum at 5.5kpa and enter the forced decarburization process: control the oxygen flow rate of the top lance at 1350Nm 3 / h, properly adjust the lifting gas flow rate, control the lifting gas flow rate from 1200Nl / min to 1800Nl / min, in order to increase the liquid steel ring flow rate, thereby increasing the decarburization speed, and control ...

Embodiment 3

[0051] Example 3, refining ferritic stainless steel with a carbon content of 0.05% (500ppm) and a nitrogen content of less than 70ppm.

[0052] A. The temperature of molten steel in the ladle is detected to be 1605°C; while the initial carbon content in the molten steel is 0.10%, and the initial nitrogen content of the treatment is 800ppm;

[0053] B. Keep the RH vacuum degree at 5.0kpa, and carry out the preliminary denitrification operation of RH vacuum. The vacuum time is maintained at 15 minutes, and the lifting gas flow rate is controlled at 1500Nl / min at this time;

[0054] C. After the end of the denitrification process, keep the RH vacuum at 5.0kpa and enter the forced decarburization process: control the oxygen flow rate of the top lance at 1500Nm 3 / h, properly adjust the lifting gas flow rate, control the lifting gas flow rate from 1200Nl / min to 1800Nl / min, in order to increase the liquid steel ring flow rate, thereby increasing the decarburization speed, and contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com