A method for preparing high-purity white solid capsaicin

A capsaicin and solid-state technology, applied in the field of extraction and separation of natural products, can solve the problems of unspecified capsaicin color, high price of capsaicin, and high production cost, and achieve the effects of reducing production cost, easy operation, and large processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Add 10g of capsicum oleoresin into a 100ml three-necked bottle, add 40g of purified water, heat to 70°C, stir for 1 hour, add 20g of ethyl acetate, continue stirring for 30 minutes, let it cool, and transfer it into a 100ml separating funnel Stand in the middle and separate layers, filter the ethyl acetate layer, concentrate the filtrate, add 20g of n-hexane to the concentrate, heat to 65°C to dissolve it completely, cool down, stir and crystallize at -7°C for 3 hours, and obtain a brown solid after suction filtration Capsaicin.

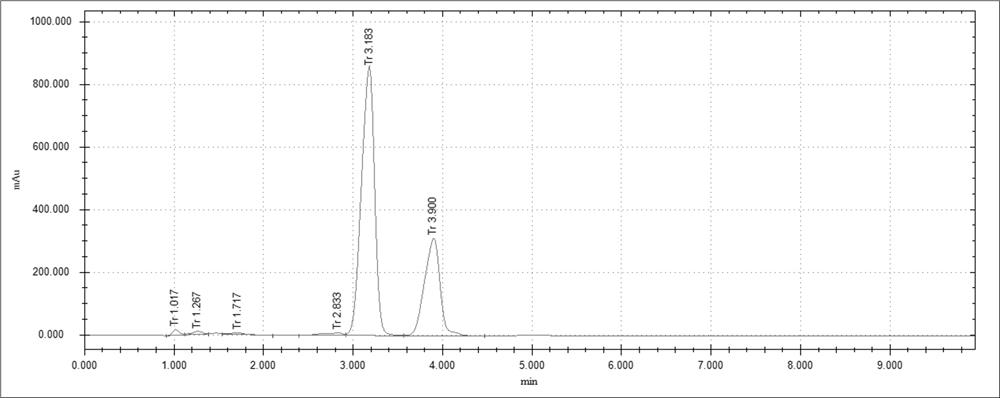

[0037] 2. Prepare a mixed solution of ethanol: ethyl acetate = 3:1 volume ratio, and filter it through a 0.45µm microporous membrane as an eluent. Take part of the eluent and soak 200g of gel Sephadex LH-20, swell for more than 6 hours, pack the column, balance 3 to 5 column volumes with the eluent, dissolve the solid capsaicin obtained in the first step with the eluting solvent, Filter with a 0.45 μm microporous membrane, load the filtrat...

Embodiment 2

[0040] On the basis of Example 1, in its step 1, capsicum oleoresin is added 50g water, after stirring for 1 hour, add 20g dichloromethane, stir 30min, after extracting liquid separation, dichloromethane layer continues to process by remaining steps, The total alkali content of capsicum is 98.2%, and the whiteness value is 70.4.

Embodiment 3

[0042] On the basis of Example 1, in its step 2, the gel type is replaced by Sepharose FF, all the other steps are carried out according to Example 1, the capsaicin total alkali content is 98.4%, and the whiteness value is 70.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com