Fiber with 4T-shaped section

A fiber and cross-section technology, applied in the field of fibers with 4 T-shaped cross-sections, can solve the problems of easy wear and tear of the spinning nozzle slit of the spinneret, no commercial product process, difficult spinning operations, etc., and achieve excellent water absorption. , Excellent moisture absorption, soft touch effect

Inactive Publication Date: 2011-11-23

SHINKONG SYNTHETIC FIBERS

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As far as the applicant knows, the spinning operation using the spinneret is difficult and there is no commercial product process, and the spinneret slit of the spinneret is easy to wear, resulting in deformation of the fiber section

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0089] melted polyester polymer Figure 6 The spinneret shown is ejected, then quenched by cooling air at 40nm / hr, and the spinning speed is 700m / min to form filaments, and the filaments are subjected to elongation ratio 2.89, 160°C shaping treatment, cooling, wrinkling, oiling, drying, Cut cotton, pack and other steps to get 3D*51mm 4T cross-section fibers, the characteristics are shown in Tables 1 and 2 below.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

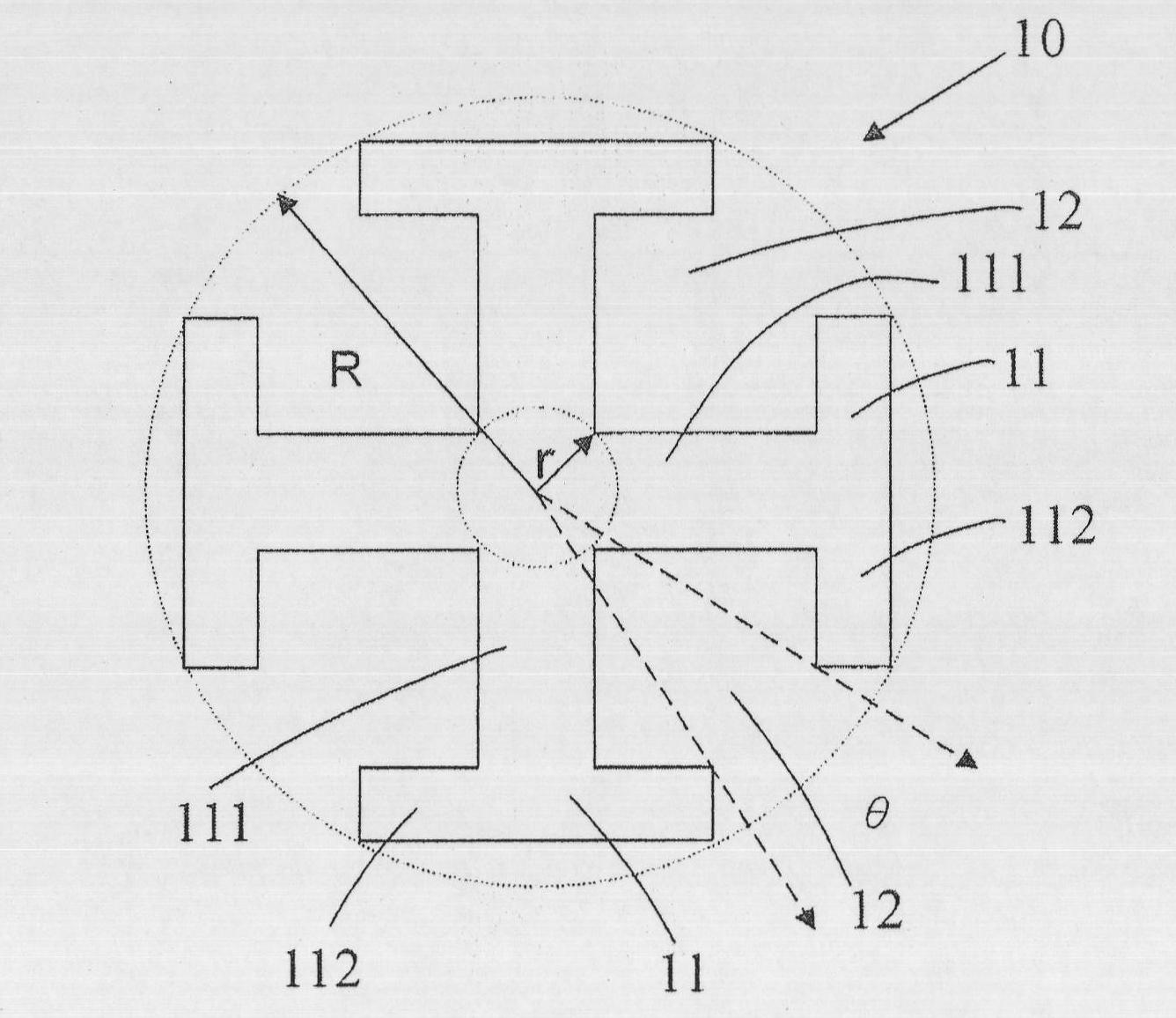

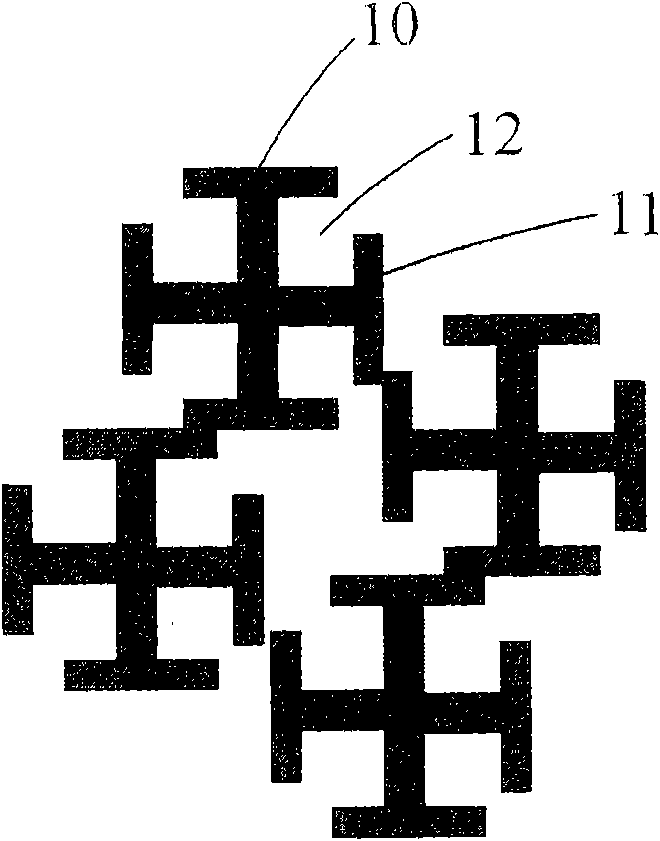

The invention discloses a fiber with a 4T-shaped section, which comprises 4 T-shaped valves, wherein each T-shaped valve comprises a cover part and a foot part; and the foot part of each T-shaped valve is connected to the center of the fiber. The T-shaped valves are separated to form an open-type hollow part between every two adjacent T-shaped valves as a guide channel. The fiber has specific Denier, open magnitude, hollow rate and degree of profile of section, so that a considerable clearance is kept between the fibers; and thus, the fabric woven by the fiber has improved functions of water absorption and quick drying, and people can feel dry, soft, comfortable and warm instead of muggy.

Description

technical field [0001] The invention relates to a fiber, especially a fiber with four T-shaped sections (4T-shaped sections). Background technique [0002] Fibers with special-shaped cross-sections, such as fibers with cross-shaped, Y-shaped, W-shaped or circular cross-sections, are prior art, and they usually have the functions of moisture absorption and perspiration. [0003] U.S. Patent No. 5,057,368 discloses a fiber with 3 or 4 T-shaped cross-sections. The T-shaped petals of the fiber have a specific relationship between length and width. The patent also discloses the spinneret used to produce such fibers plate. As far as the applicant knows, the spinning operation using the spinneret is difficult and there is no commercial product process, and the spinneret slit of the spinneret is easy to wear and tear, resulting in deformation of the fiber section. [0004] Therefore, need badly a kind of fiber that can manufacture simplification, the fabric that it is woven has ex...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01D5/253

Inventor 吴国忠

Owner SHINKONG SYNTHETIC FIBERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com