Traversing construction method for tie bar arch

A construction method and tie-arch technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of unsatisfactory laying construction period, complicated construction process, and extended construction period, so as to save daily maintenance costs and shorten the construction period , The effect of saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

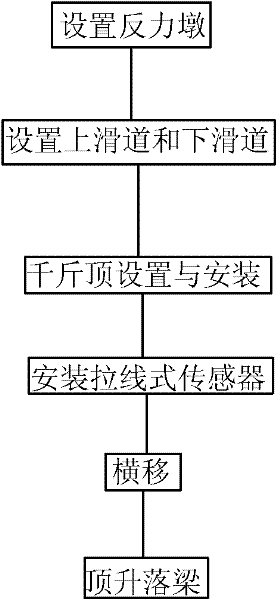

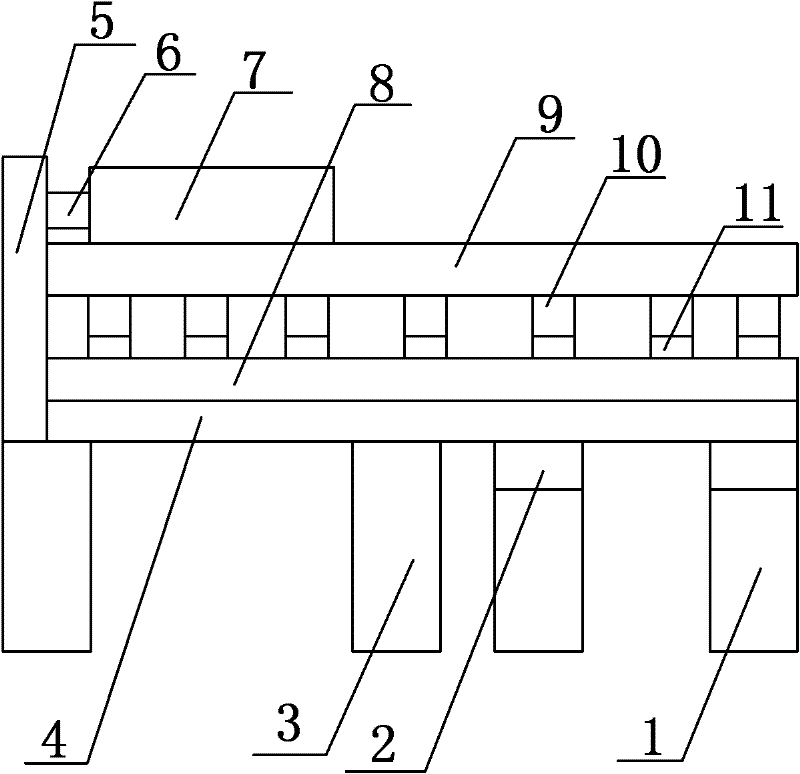

[0021] Such as figure 1 and figure 2 A tie arch transverse movement construction method is shown, including main pier 1, temporary pier 3 and tie arch 7, the span of tie arch 7 is 64m, and the transverse movement method includes the following steps:

[0022] Step 1. Set up the reaction pier 5: The reaction pier 5 is a steel structure, which is installed on the upper surface of the end of the temporary pier 3, connected with the temporary pier 3 through anchor bolts, and the reaction pier 5 and the temporary pier 3 are constructed at the same time or pass through It is formed by pouring reinforcement on the temporary pier 3;

[0023] Step 2: Set up the upper slideway 9 and the glideway: the upper slideway 9 and the glideway are set between the tie rod arch 7 to be traversed, the main pier 1 and the temporary pier 3, and the upper surface of the main pier 1 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com