Bridge erection machine aided support leg structure

A technology for auxiliary outriggers and bridge erecting machines, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., which can solve problems such as inconvenient installation, low safety factor, and difficult processing, and achieve high flexibility, easy installation, and processing The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

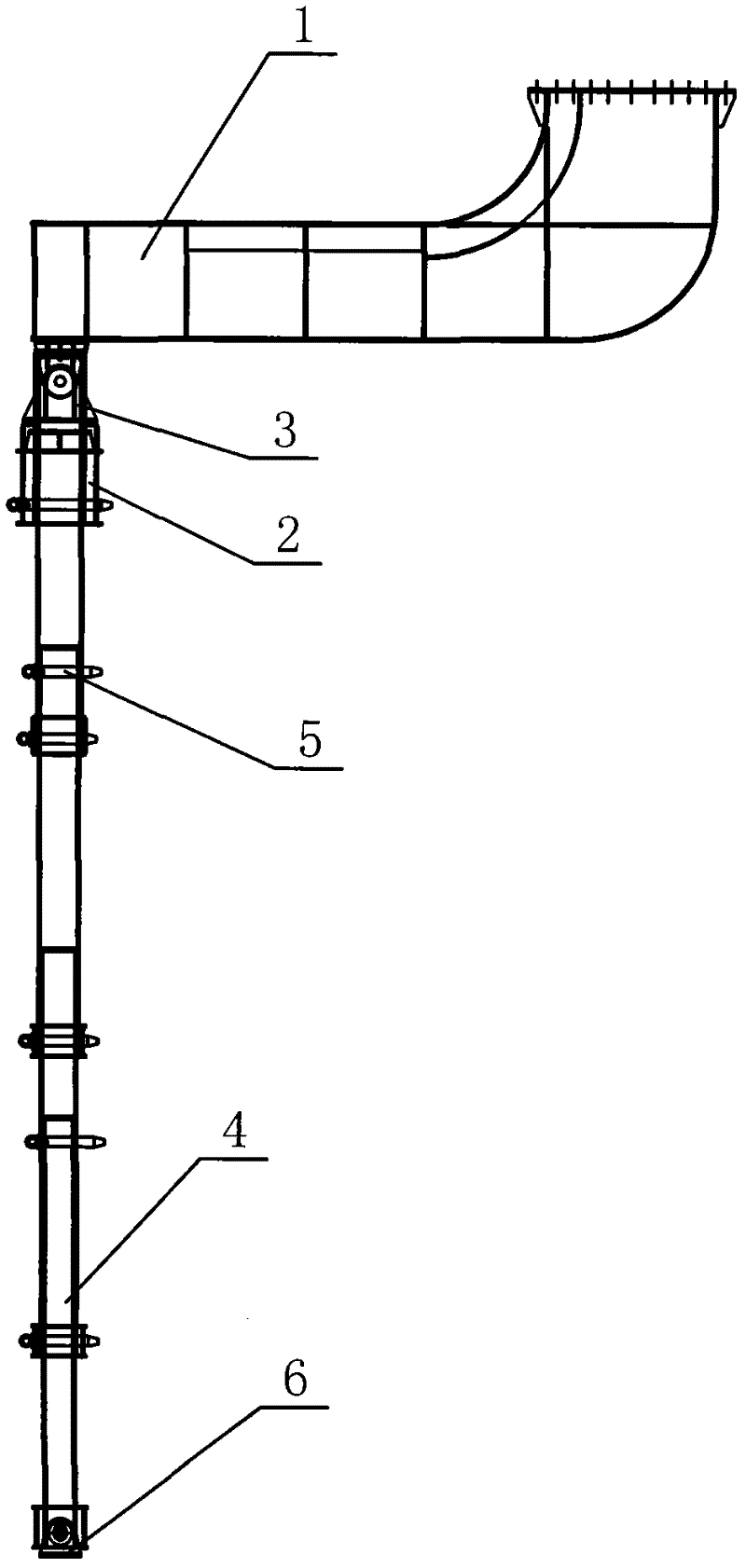

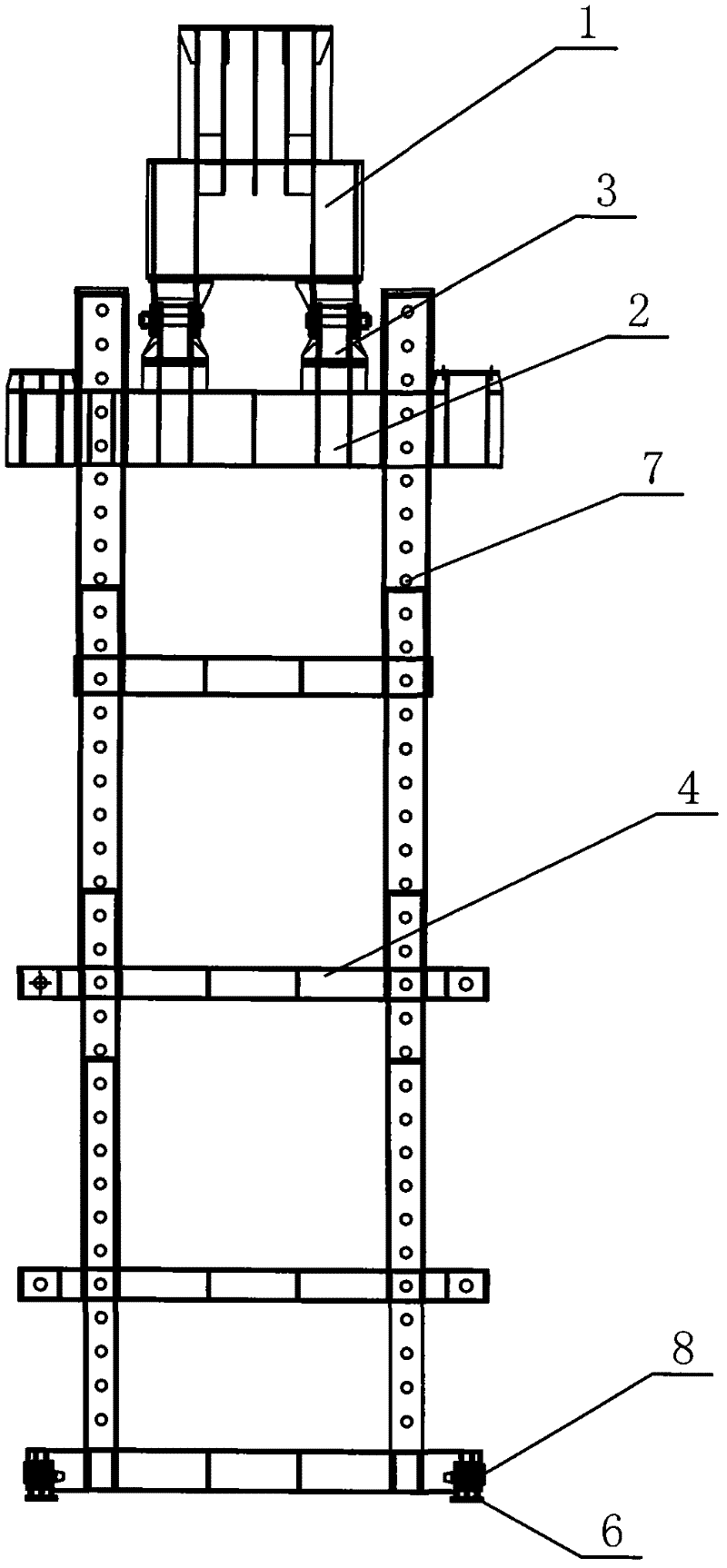

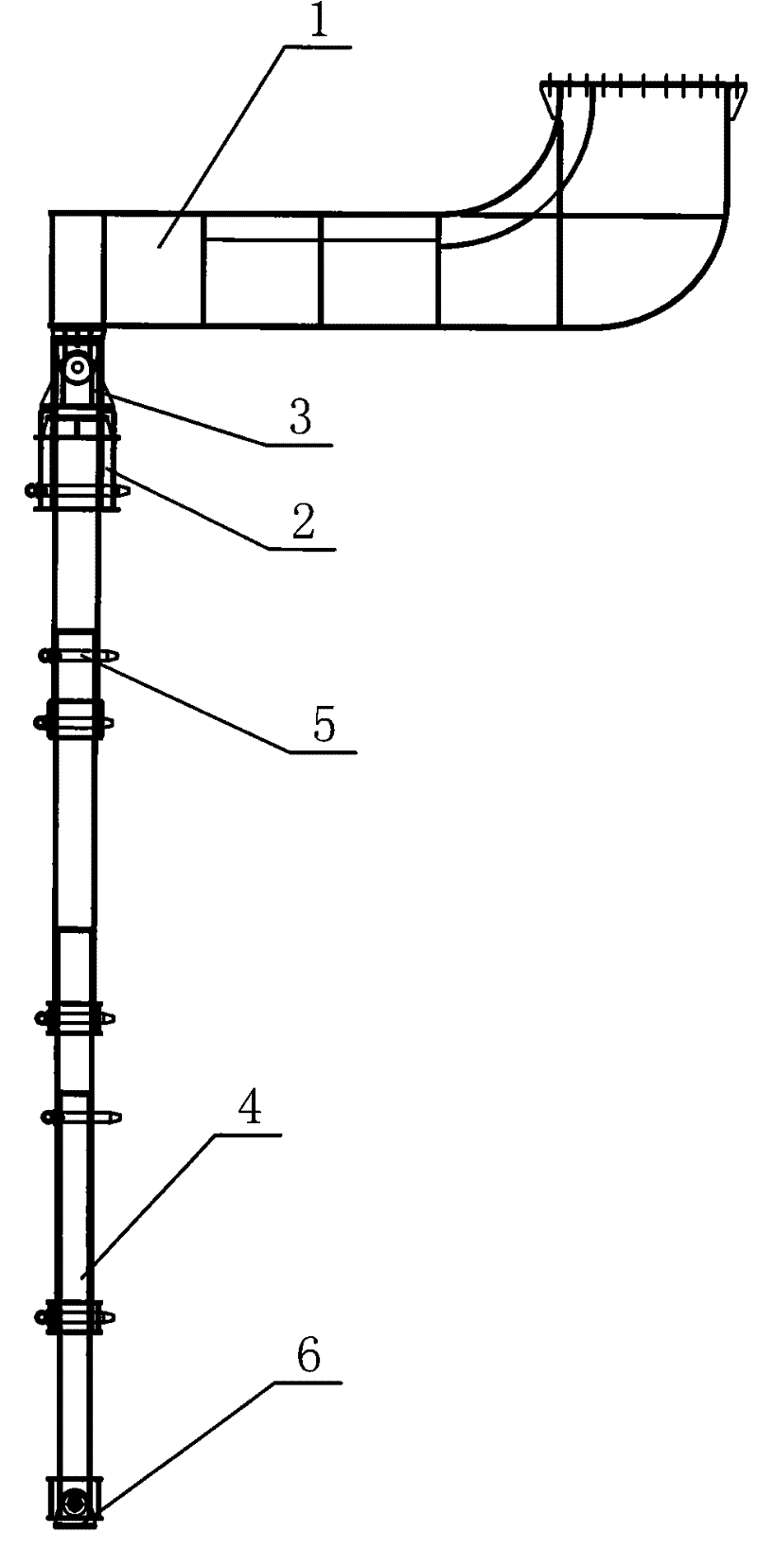

[0013] Please refer to figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of the auxiliary leg structure of the bridge erecting machine of the present invention; figure 2 It is a cross-sectional view of the auxiliary leg structure of the bridge erecting machine of the present invention.

[0014] In this embodiment, the auxiliary outrigger structure of the bridge erecting machine is composed of four telescopic joints 4 suitably spliced together. The telescopic joints 4 are circular tube structures, and several height adjustment holes are opened on the surface of the circular tubes. 7. The height adjustment hole 7 is provided with a pin 5, the pin 5 passes through the height adjustment hole 7 corresponding to two adjacent expansion joints 4 to connect the two expansion joints 4, and the auxiliary leg structure of the bridge erecting machine One end is hinged on the support 6 through the support steel pin 8, and the other end is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com