Jacking-up mechanism of sleeve roller chains

A sleeve roller chain and jacking mechanism technology, which is applied in the field of lifting machinery, can solve problems such as installation, use restrictions, complex structure of key parts, and deep machine pit, and achieve the effects of convenient manufacture, simple structure, and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

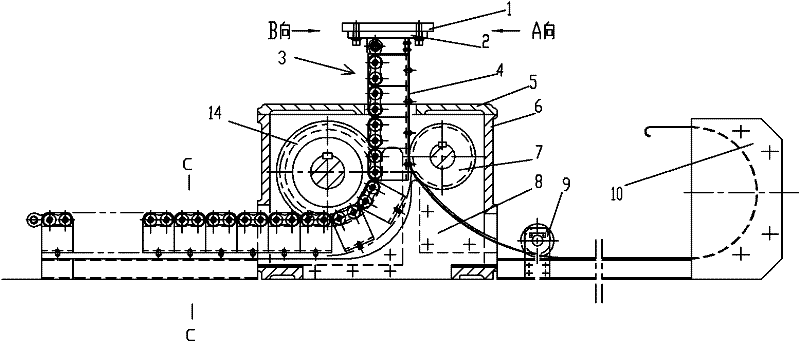

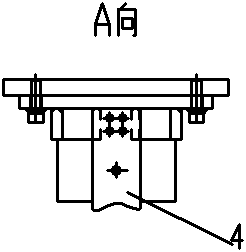

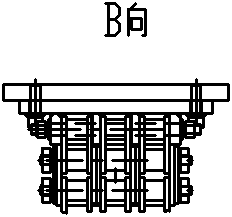

[0031] see Figure 1~Figure 11 Shown: a sleeve roller chain jacking mechanism, which includes a drive box 6, a roller chain 3 with U-shaped attachments, and standard three rows (three rows in this embodiment) or multiple rows with U-shaped The length of the U-shaped attachment 3.2 on the roller chain in attachment 3.2 is changed to two chain pitch lengths (that is, the longitudinal length of the U-shaped attachment is changed to 2p, and p is the chain pitch), so that the U-shaped attachment of the end-to-end chain link The end faces are precisely close together so that the chain cannot be bent, and one side is a rigid pillar that bears pressure. A protruding locking pin 3.3 is provided on the outer plane of each U-shaped attachment; A top plate 2 is connected, and a locking steel band 4 extending downward is connected to the outer plane side of the U-shaped attachment under the top plate 2. On the locking steel band 4, there is a corresponding matching lock pin 3.3 on the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com