Mountain flour plugging method

A plugging method and stone powder technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of inability to form an overall blockage body and insufficient blockage strength, and achieve high pressure bearing capacity, Improve the success rate and anti-breaking ability, improve the effect of matching ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

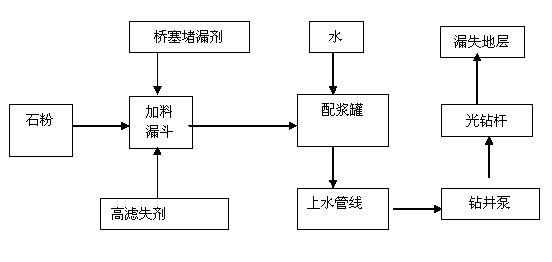

Embodiment 1

[0031] The invention discloses a stone powder composite bridge plug plugging method. The stone powder composite bridge plug plugging slurry is prepared through a drilling fluid mixing tank, which is composed of A high fluid loss agent XHD, B stone powder, C bridging agent and water, wherein , high fluid loss agent accounts for 14-20% of the total water weight, stone powder accounts for 50-100% of the total water weight, and bridging agent accounts for 10-15% of the total water weight. The volume of the slurry mixing tank is generally 30-40m3, put two-thirds of the total amount of clean water in the slurry mixing tank, and start the agitator on the slurry mixing tank at the same time, and the drilling pump circulates through the hydraulic mixing funnel tank with a displacement of 1.8 cubic meters per minute According to the feeding sequence of A, B and C, prepare in the hydraulic mixing funnel. After the preparation, the plugging slurry should be put into the well as soon as pos...

Embodiment 2

[0038] Prepare stone powder composite bridge plug plugging slurry through the slurry mixing tank of drilling fluid, the volume of the mixing slurry tank is 30-40m 3 , put two-thirds of the total amount of clean water in the mud mixing tank, and start the agitator on the mud mixing tank at the same time, and the drilling pump circulates in the mud mixing tank through the hydraulic mixing funnel with a displacement of 1.8 cubic meters per minute. Add fluid loss agent, accounting for 14-20% of the total water weight, add stone powder, accounting for 50-100% of the total water weight, and finally add bridging agent, accounting for 10-15% of the total water weight. , After the preparation, the plugging slurry should be put into the well as soon as possible. If the time exceeds 4 hours, the stratification is serious and partly solidified.

Embodiment 3

[0040]On the basis of Example 2, the bare drill pipe is lowered to 10-30 meters above the leakage zone, and the internal volume of the drilling tool is calculated, and the leakage plugging slurry in the tank is evenly pumped by the drilling pump at a speed of 1.8 cubic meters per minute. Plugging slurry. Measure the amount of plugging slurry entering the well and the amount of drilling fluid returning out of the tank every minute, and calculate the loss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com