Hydraulic cylinder test device and method under simulated working condition

A test device and hydraulic device technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problem of unilateral wear of piston rod and seal, on-site environmental pollution of hydraulic cylinder, and difficulty in meeting the requirements of Party A. and other problems to achieve the effect of ensuring the accuracy of detection, improving the quality of restoration, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

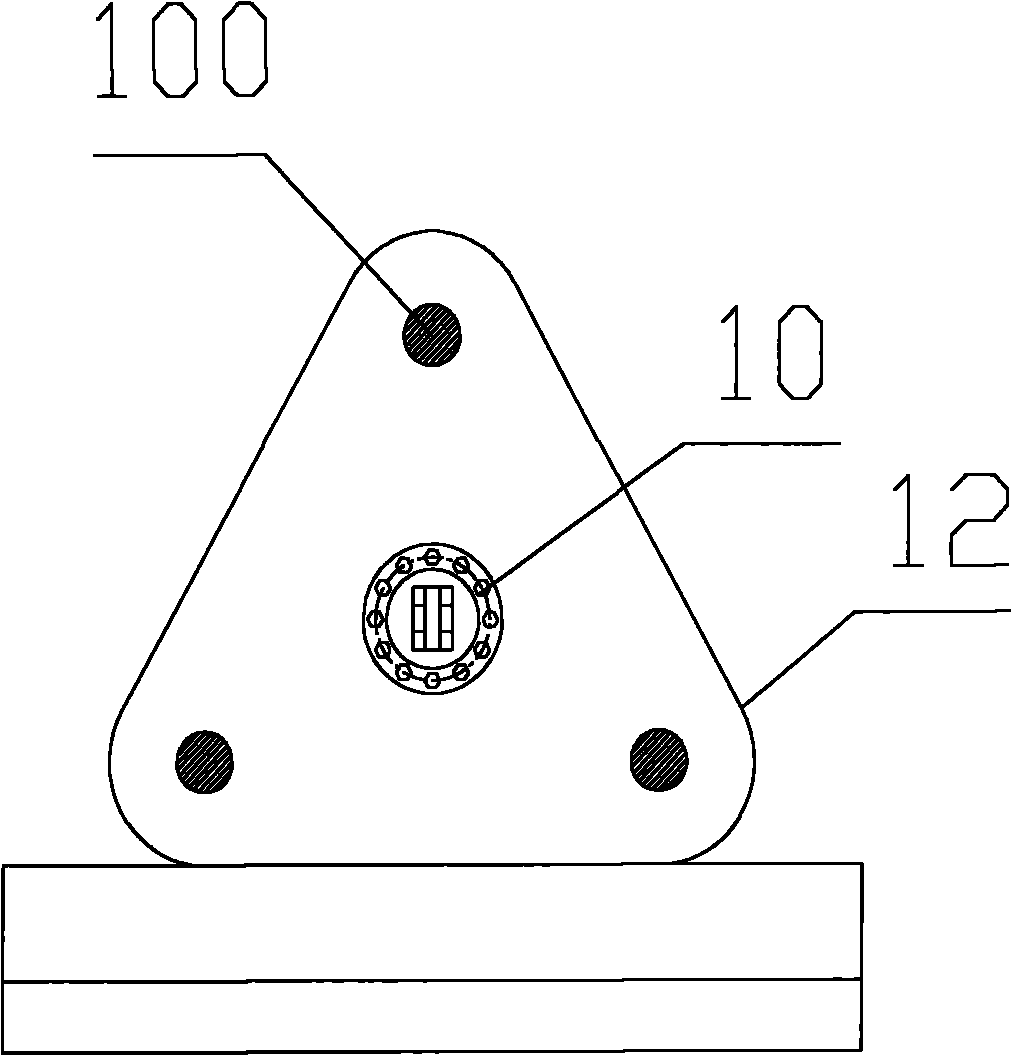

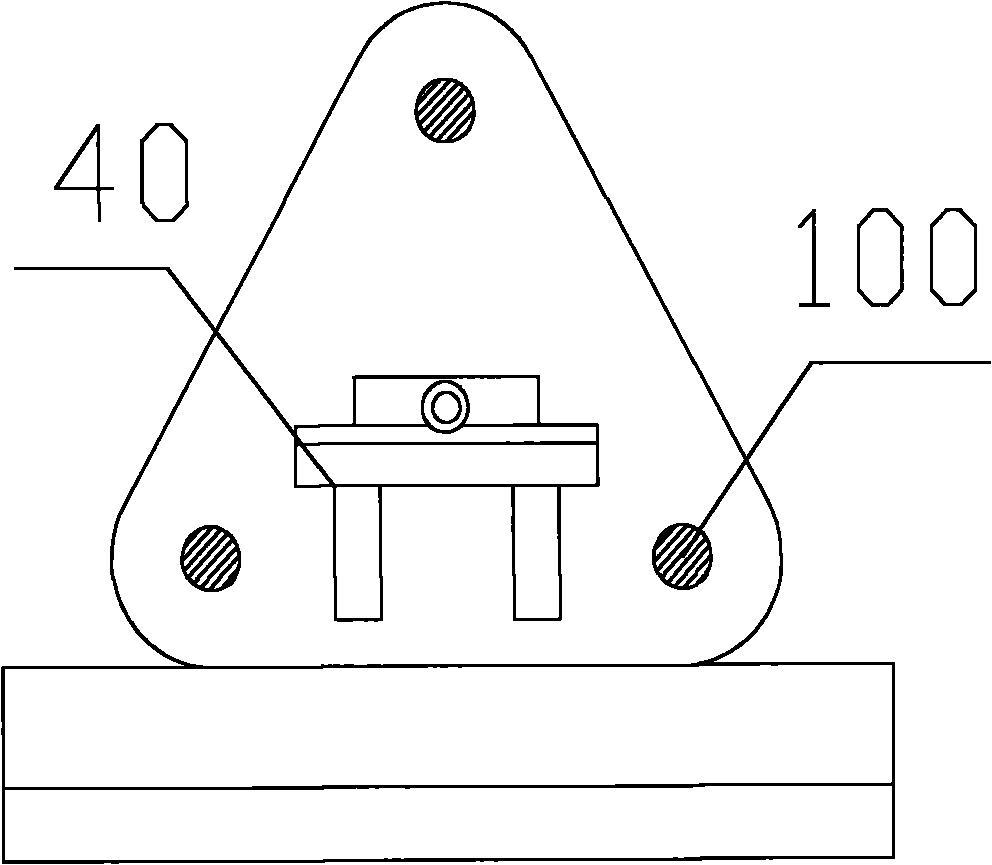

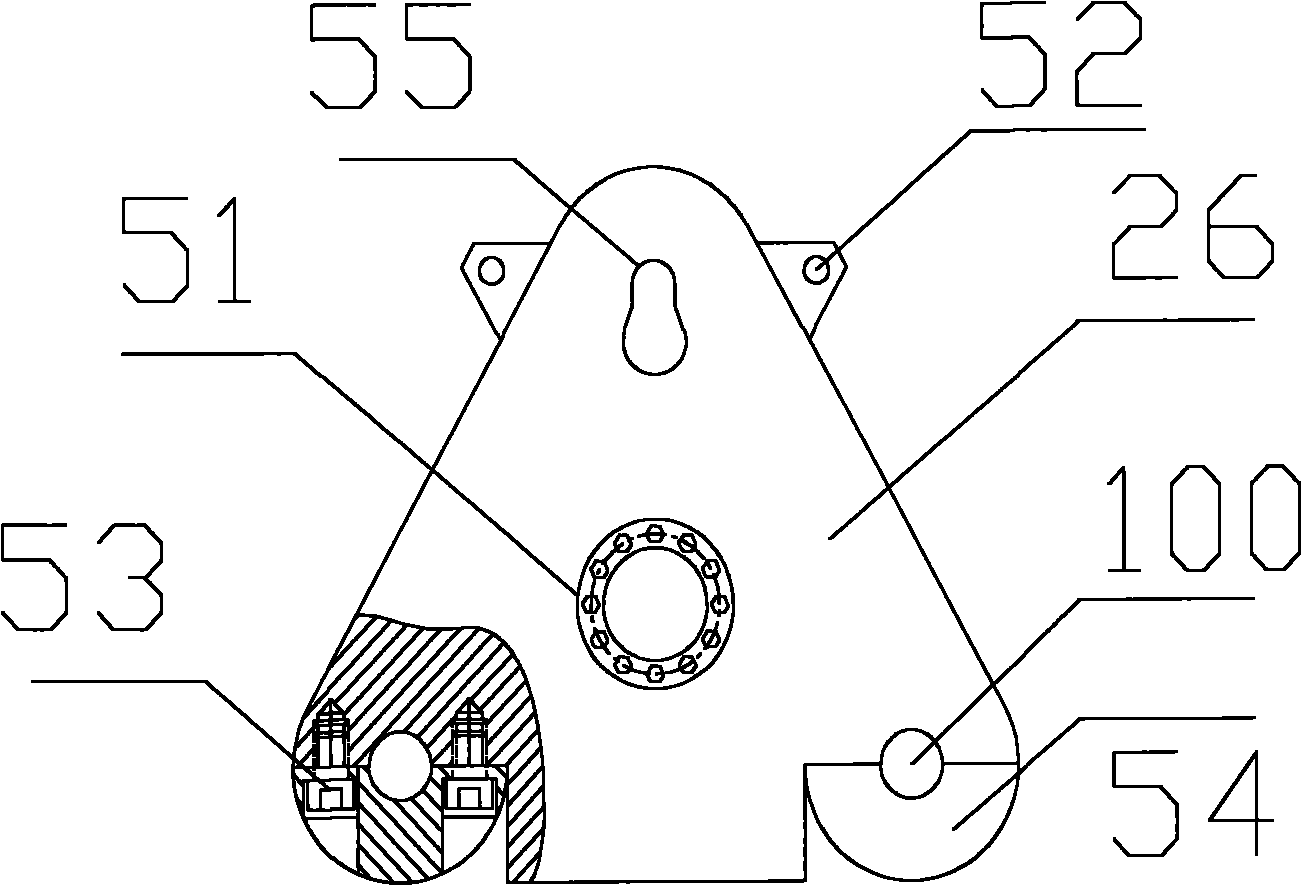

[0032] The reference signs and components involved in the accompanying drawings are as follows:

[0033] 10 Trunnion support 12 Fixed triangular plate

[0034] 20 Tested oil cylinder 21V type iron

[0035] 22 jack 24 fixed guide rail

[0036] 26 Movable triangular plate 27 Trunnion connector between tested oil cylinder and loading oil cylinder

[0037] 30 Base 32 Handle for connecting oil cylinder

[0038] 35 Loading cylinder for trunnion type cylinder test 36 Base mounted cylinder for loading test

[0039] 40 Support base 51 Bottom plate for fixing oil cylinder or trunnion

[0040] 52 hoisting holes for hoisting and moving movable triangle plate 53 bolts

[0041] 54 semi-circular ring for fixed movable triangular plate 55 taper hole

[0042] 100 rail holes

[0043] Please see figure 1 , figure 2 and image 3 . figure 1 It is a schematic diagram of the structure of the fixed triangular plate in the tripod for the cylinder test. figure 2 It is a schematic diagram ...

Embodiment 2

[0051] Embodiment 2 Conventional hydraulic cylinder test method (taking the trunnion type hydraulic cylinder experiment as an example)

[0052] Test method for external leakage of hydraulic cylinder

[0053] according to Figure 4 Install the tested hydraulic cylinder, loading hydraulic cylinder, hydraulic pipeline, etc. in place, connect the tested hydraulic cylinder with the loading cylinder with a trunnion connector, and adjust the centering with the adjustment guide frame.

[0054] Please see Figure 10A , open the hydraulic system of the hydraulic cylinder under test, switch the reversing valve 230 to the left position, adjust the one-way throttle valve 211; switch the reversing valve 230 to the right position, adjust the one-way throttle valve 212; make the piston reciprocate multiple times, Side by side despite the air in the channel, when the measured hydraulic cylinder 222 is in place, adjust the overflow valve 209 to use as a safety valve, adjust the overflow valve...

Embodiment 3

[0059] Embodiment 3 Hydraulic cylinder withstands impact load test method (taking the trunnion type hydraulic cylinder experiment as an example)

[0060] Please see Figure 10B , install the tested hydraulic cylinder 222, the impact slide valve 223, etc., open the tested hydraulic cylinder 222, load the hydraulic cylinder to test the hydraulic system, switch the reversing valve 230 to the left position, and adjust the overflow valve 309 to gradually pressurize to 120% of the load pressure , load the cylinder to simulate the load and push the hydraulic cylinder under test. When the piston of the hydraulic cylinder under test moves to the position to be tested, close the high-pressure ball valves 210, 220, 270, and 280; close the high-pressure ball valves 360, 370, 380, and 390, and open the high-pressure ball valves. 310, 3201, 340, 350 At this time, the hydraulic system of the loading hydraulic cylinder adopts the impact hydraulic circuit composed of the quick reversing valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com