Extension testing device

A test device and test piece technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of low precision, insufficient power of the biaxial tensile testing machine, limited loading ratio, etc., and achieve a large test tension range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

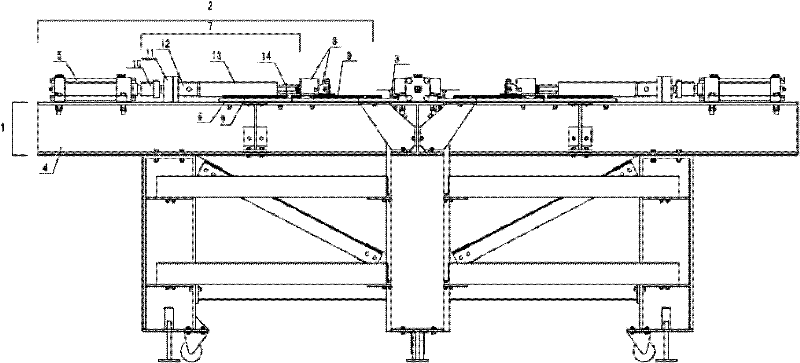

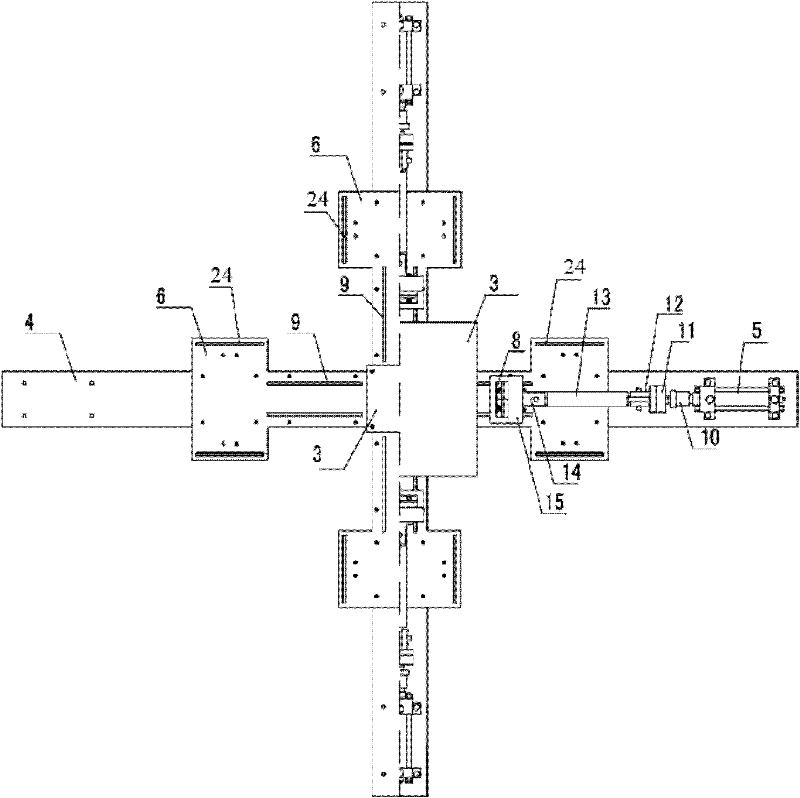

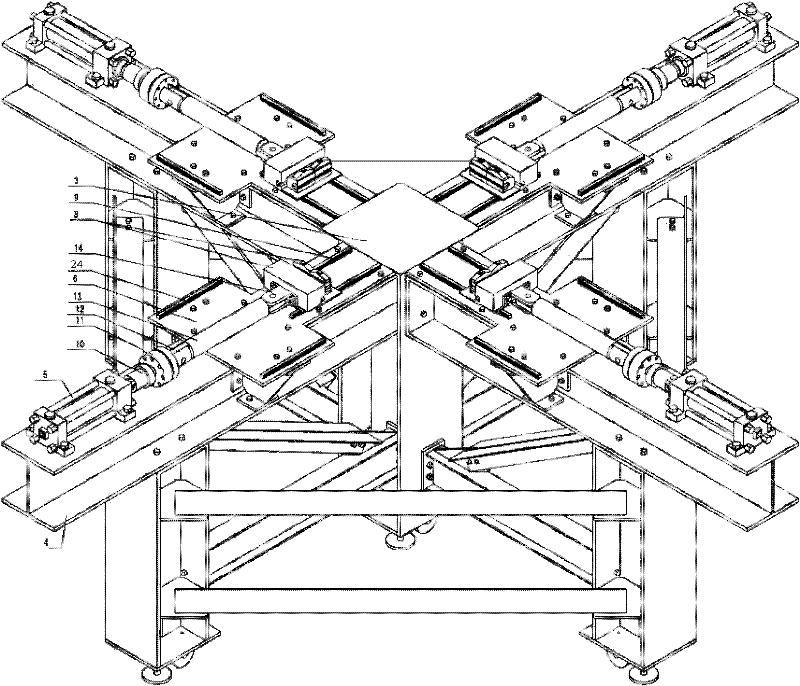

[0032] Such as figure 1 , figure 2 with image 3 As shown, this embodiment includes: a vehicle frame assembly 1, four sets of stretching mechanisms 2 and a specimen fixing assembly 3, wherein: the vehicle frame assembly 1 is fixedly connected to the four sets of tensioning mechanisms 2 and the specimen fixing assemblies 3 respectively.

[0033] The vehicle frame assembly 1 includes four sets of stands 4 distributed orthogonally, and the four sets of stands 4 are connected with the four sets of stretching mechanisms 2 in one-to-one correspondence.

[0034] The stretching mechanism 2 includes: an oil cylinder 5, a guide rail support plate 6, a tension conversion assembly 7, a clamping assembly 8 and a linear guide rail 9, wherein: the oil cylinder 5 is fixedly connected to the end of the stand 4, and the guide rail support plate 6 is connected to the stage The frame 4 is fixedly connected, the oil cylinder 5 is connected with the tension conversion assembly 7, the linear guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com