Device for testing tension of test piece

A tensile test and test piece technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of inconvenient use of optical measurement systems, complex structure of tensile testing machines, and large space occupation. Smooth process without vibration, light weight, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

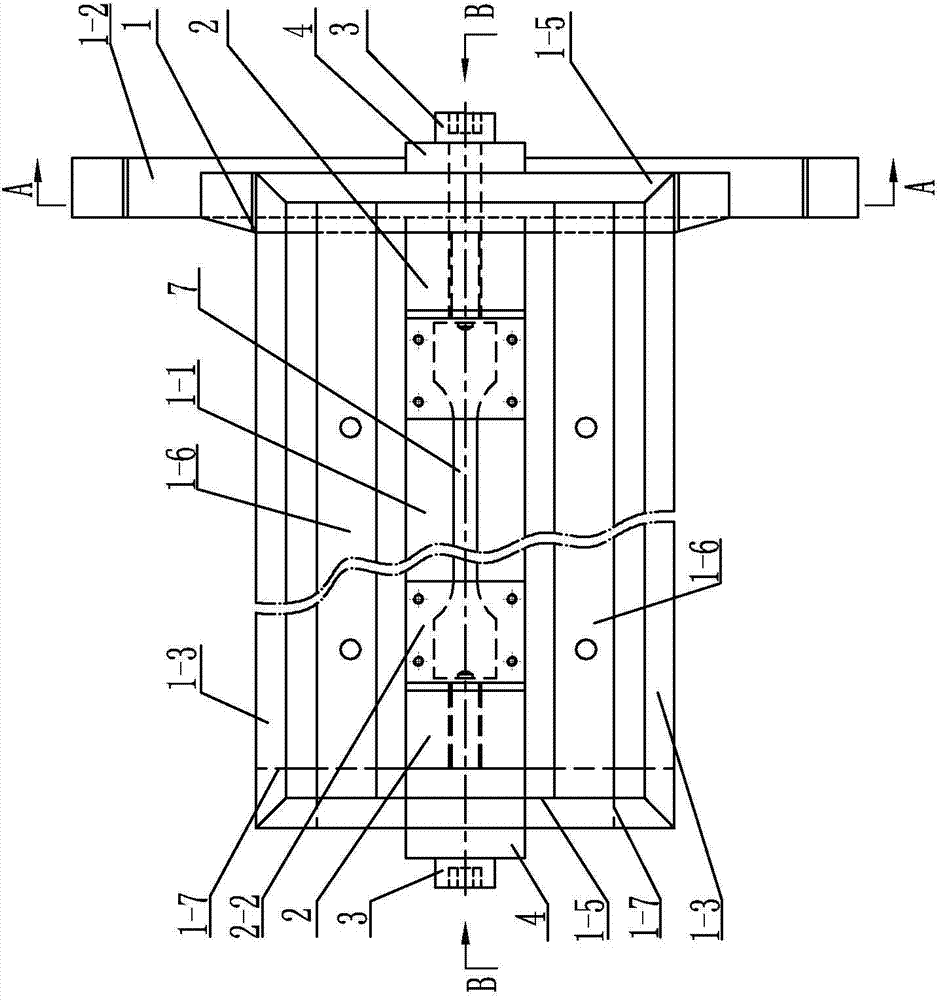

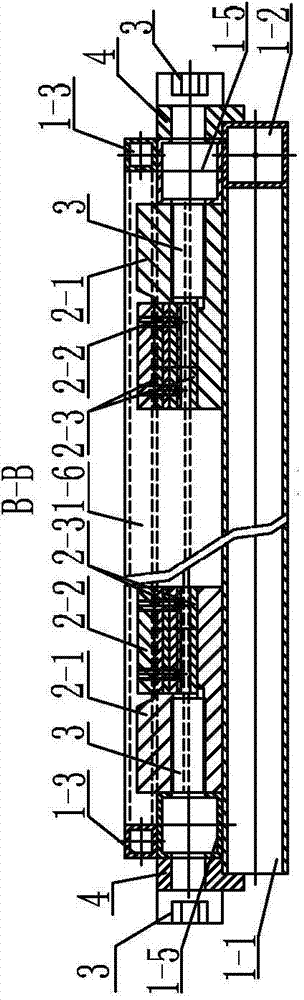

[0008] Specific implementation mode one: combine Figure 1 to Figure 10 To illustrate this embodiment, a device for tensile testing of specimens in this embodiment includes a base 1, two chuck assemblies 2, two pretensioners 3 and two top plates 4;

[0009] Each set of chuck assembly 2 includes a card seat 2-1, a cover plate 2-2 and a plurality of backing plates 2-3, the card seat 2-1 is provided with a groove 2-6, and the size of the groove 2-6 The shape is the same as the size and shape of the end of the test piece 7 to be stretched. The side wall of the holder 2-1 is provided with a threaded hole 2-4 communicating with the groove 2-6, and the axial direction of the threaded hole 2-4 is Consistent with the length direction of the test piece to be stretched, the size and shape of the backing plate 2-3 are the same as the size and shape of the groove 2-6, and the backing plate 2-3 is placed in the groove 2-6 to support the test piece to be stretched. The piece 7 and the cover...

specific Embodiment approach 2

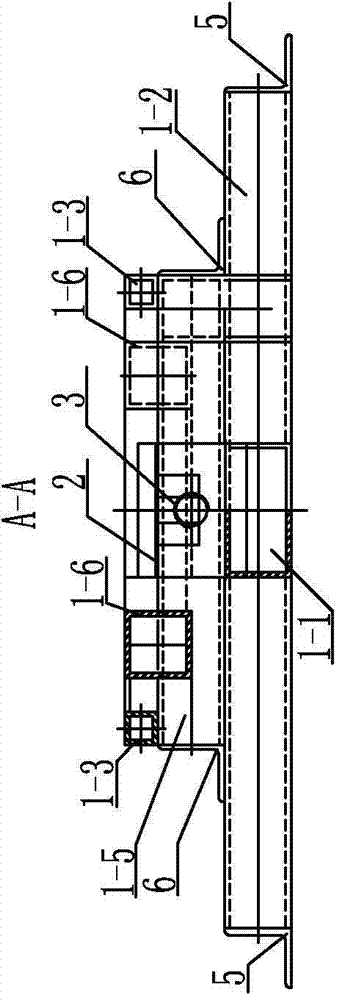

[0011] Specific implementation mode two: combination Figure 1 to Figure 6 To illustrate this embodiment, the base 1 in this embodiment includes a first square pipe 1-1, a second square pipe 1-2, a square frame 1-3, two third-party pipes 1-5, and two fourth square pipes 1-6 and two fifth square pipes 1-7, the second square pipe 1-2 is set horizontally, and one of the third-party pipes 1-5 is stacked on the second square pipe 1-2, and the length direction of the two is the same , two fifth square pipes 1-7 are vertically arranged side by side, another third-party pipe 1-5 is connected between the two fifth square pipes 1-7, two third-party pipes 1-5 are arranged side by side, two Two fourth square pipes 1-6 are arranged side by side between the first third-party pipes 1-5, and the length direction of the two fourth square pipes 1-6 is perpendicular to the length direction of the two third-party pipes 1-5. The first square pipe 1-1 connected to the other third party pipe 1-5 an...

specific Embodiment approach 3

[0012] Specific implementation mode three: combination Figure 1 to Figure 6 To illustrate this embodiment, the base 1 in this embodiment also includes two first angle steels 5 and two second angle steels 6, and the two ends of the second square pipe 1-2 are respectively connected with a first angle steel 5, wherein Two ends of a third-party pipe 1-5 are respectively connected with a second angle steel 6, and two second angle steels 6 are connected with the first square pipe 1-1. Such setting facilitates the fixing of the second square tube and the third party tube, increases the rigidity of the entire base, and prevents the specimen from bending or torsional deformation or lateral translation during the loading process. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com