Appearance inspection apparatus

A visual inspection device and technology for objects, which are applied to measurement devices, use optical devices, and perform material analysis by optical means, etc., can solve problems such as dead angles in the shooting direction, inability to perform inspections correctly, etc., to improve shutter speed and achieve visual inspection. , high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] One of the specific embodiments of the present invention will be described below with reference to the drawings.

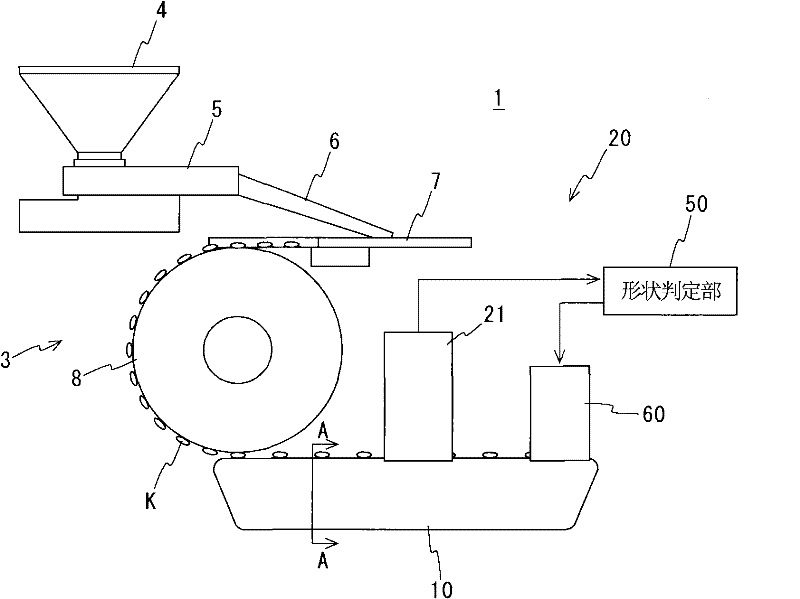

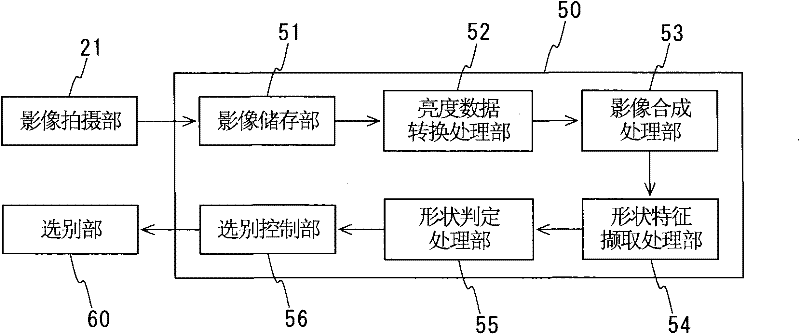

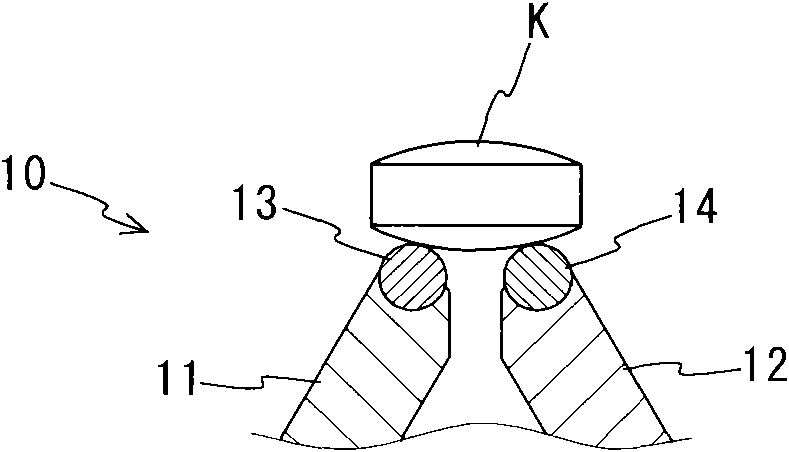

[0059] Such as figure 1 As shown, the visual inspection device 1 of this embodiment includes: a supply unit 3 for arranging and supplying the inspection object K; a linear conveyance unit 10 for linearly conveying the supplied inspection object K; and inspecting the surface of the conveyed inspection object K. shape and to be selected by the surface shape inspection unit 20.

[0060] In addition, the test object K in this embodiment is pharmaceuticals (tablets, capsules, etc.), food, mechanical parts, electronic parts, etc., but is not limited to them at all.

[0061] The details of each of the above-mentioned parts are described below.

[0062] [Supply Department]

[0063] The supply part 3 includes a hopper 4 for dropping a plurality of inspection objects K; a vibrating feeder 5 for advancing the inspection objects K discharged from the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com