Multielement standard solution for component analysis of alloying element in steel and preparation method

An alloy element and component analysis technology, which is applied in the analysis of materials, material analysis through optical means, and metal testing, can solve the problems of blank multi-element standard solutions, difficulty in eliminating iron matrix interference, matrix matching matrix interference, etc., to achieve Realize the traceability of the quantity value, realize the traceability, and eliminate the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

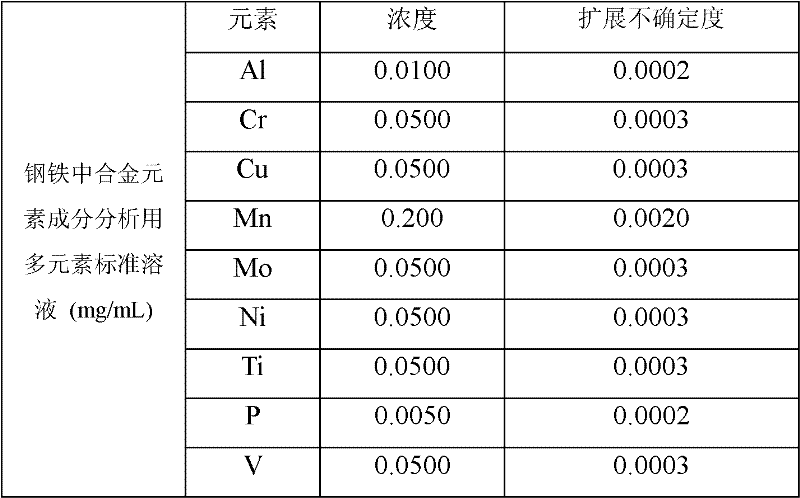

[0019] The elements contained in a multi-element standard solution for alloy element composition analysis in steel are aluminum (Al), chromium (Cr), copper (Cu), manganese (Mn), nickel (Ni), molybdenum (Mo), vanadium (V), titanium (Ti), phosphorus (P);

[0020] The content of each element is shown in Table 1.

[0021] Table 1 The content of each element in the multi-element standard solution for the analysis of alloying elements in steel

[0022]

[0023] A method for preparing a multi-element standard solution for alloy element composition analysis in steel is as follows:

[0024] (1). Establish a laboratory with a constant temperature of 20°C, a humidity control of 70% to 80%, and a cleanliness of 10,000, and a test bench with a cleanliness of 100;

[0025] (2). Weigh respectively 0.1000g of high-purity chromium with a purity of 99.95%, 0.1000g of high-purity copper with a purity of 99.99%, 0.1000g of high-purity nickel with a purity of 99.99%, 0.1000g of high-purity ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com