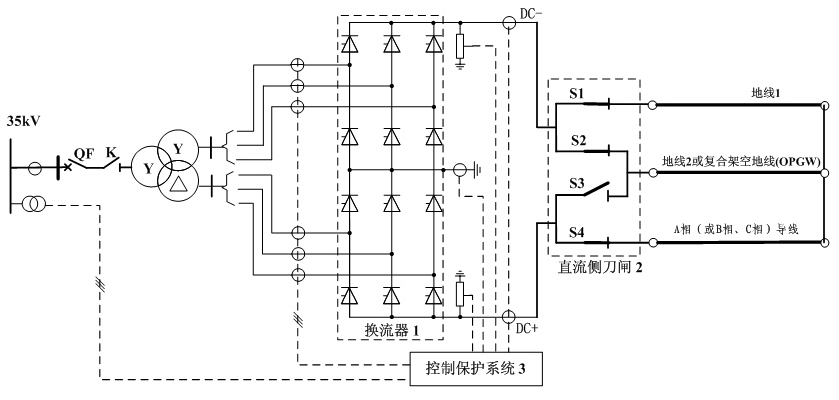

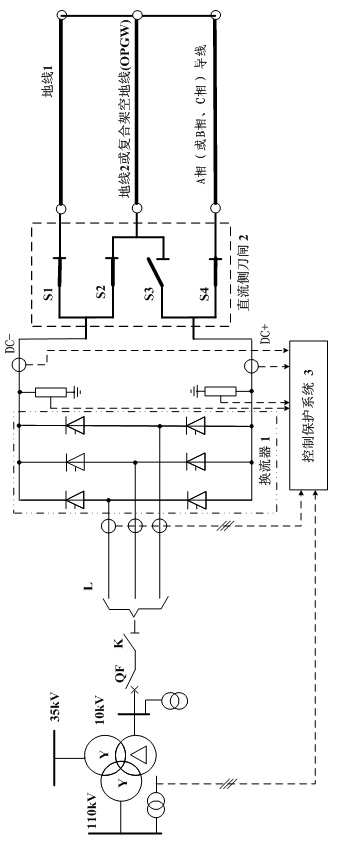

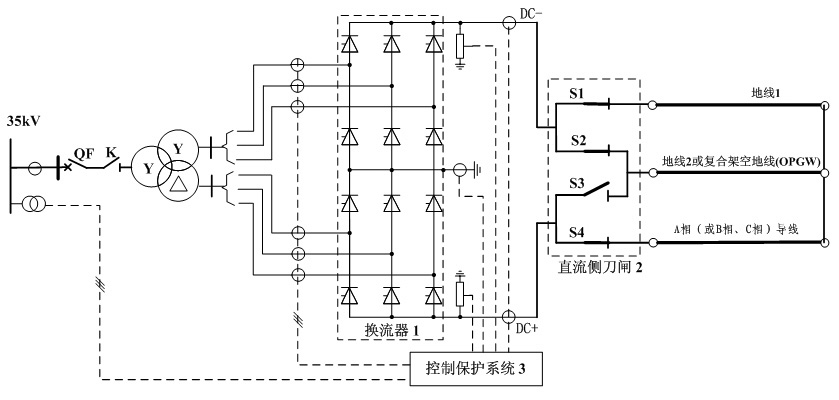

Direct-current de-icing method of overhead ground wire and composite optical fibre ground wire

A composite optical fiber ground wire, DC ice melting technology, applied in overhead installation, cable installation, electrical components, etc. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Table 1 shows the calculation of parameters related to ice melting of a 500kV AC transmission line conductor, and table 2 shows the basic situation of the overhead ground wire. If the two overhead ground wires are not fully electrically connected and insulated, the DC ice melting work cannot be carried out. If only the electrical connection of the whole line is carried out without changing the overhead ground wire to a ground wire with basically the same resistivity, the DC voltage drop required for melting the ground wire is about 74.1kV (see Table 3), which is much higher than that of wire melting. The 20.4kV required by the ice cannot use the same DC ice melting device to melt the wires and ground wires. In order to be able to perform DC deicing on the transmission line, the following work should be carried out:

[0032] (1) The ice melting parameters of the transmission line conductors are shown in Table 1, the ice melting current is 4389A, and the DC voltage drop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com