Voltage compensation structure of third winding of variable-flux voltage-regulating autotransformer and transformer

An autotransformer, voltage compensation technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor components, circuits, etc. Three windings etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

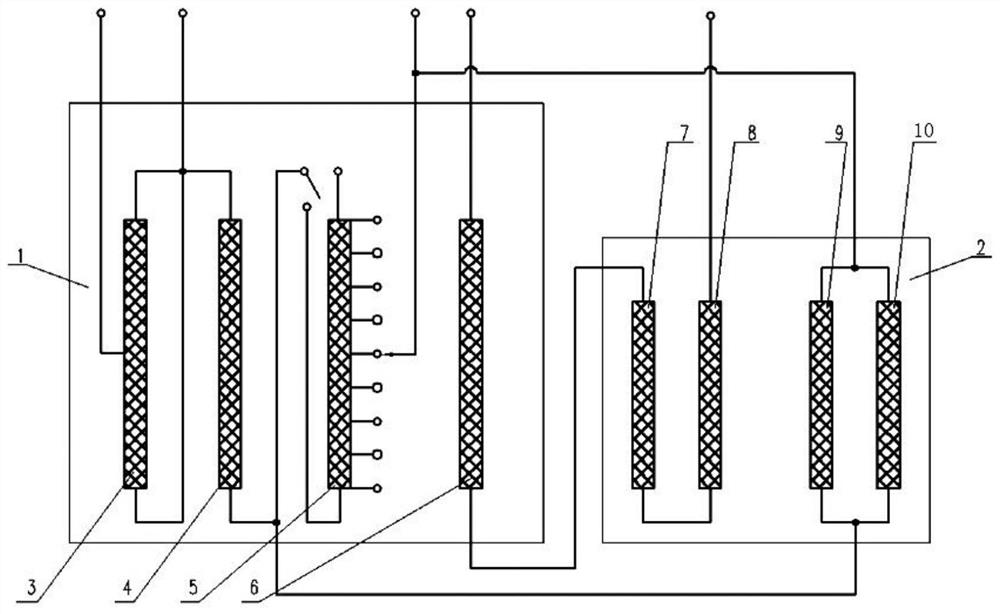

[0018] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail:

[0019] In the existing flux-changing autotransformer, the magnetic fluxes of the body 1 of the main transformer and the body 2 of the compensation transformer are relatively independent, and the voltage regulating winding 5 of the main transformer is connected with the first excitation winding 9 and the second excitation winding 9 of the compensation transformer. Windings 10 are connected in parallel. The voltage regulating winding 5 of the main transformer is located at the end of the common winding 4. When the gear of the switch is adjusted, the magnetic flux density in the iron core will change (variable flux voltage regulation), thereby causing the voltage fluctuation of the third winding 6. In order to keep the voltage of the third winding 6 constant, it is necessary to design a compensation winding connected in series with the third winding for compens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com