Method for chassis measurement and a device for measuring the chassis geometry of a vehicle

A driving mechanism and a technology for measuring parameters, which are applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of easy damage or deformation, expensive, troublesome and expensive, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

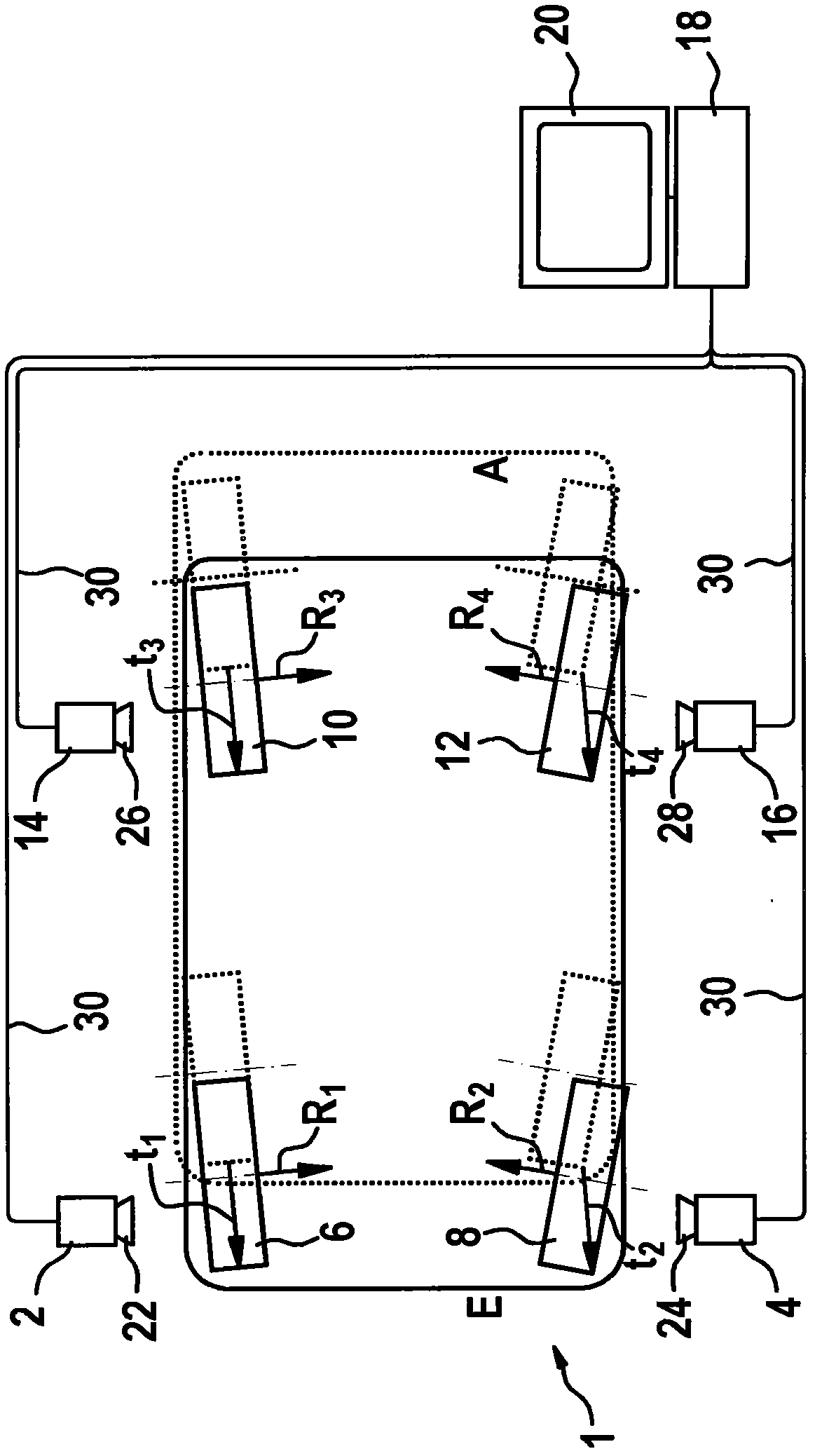

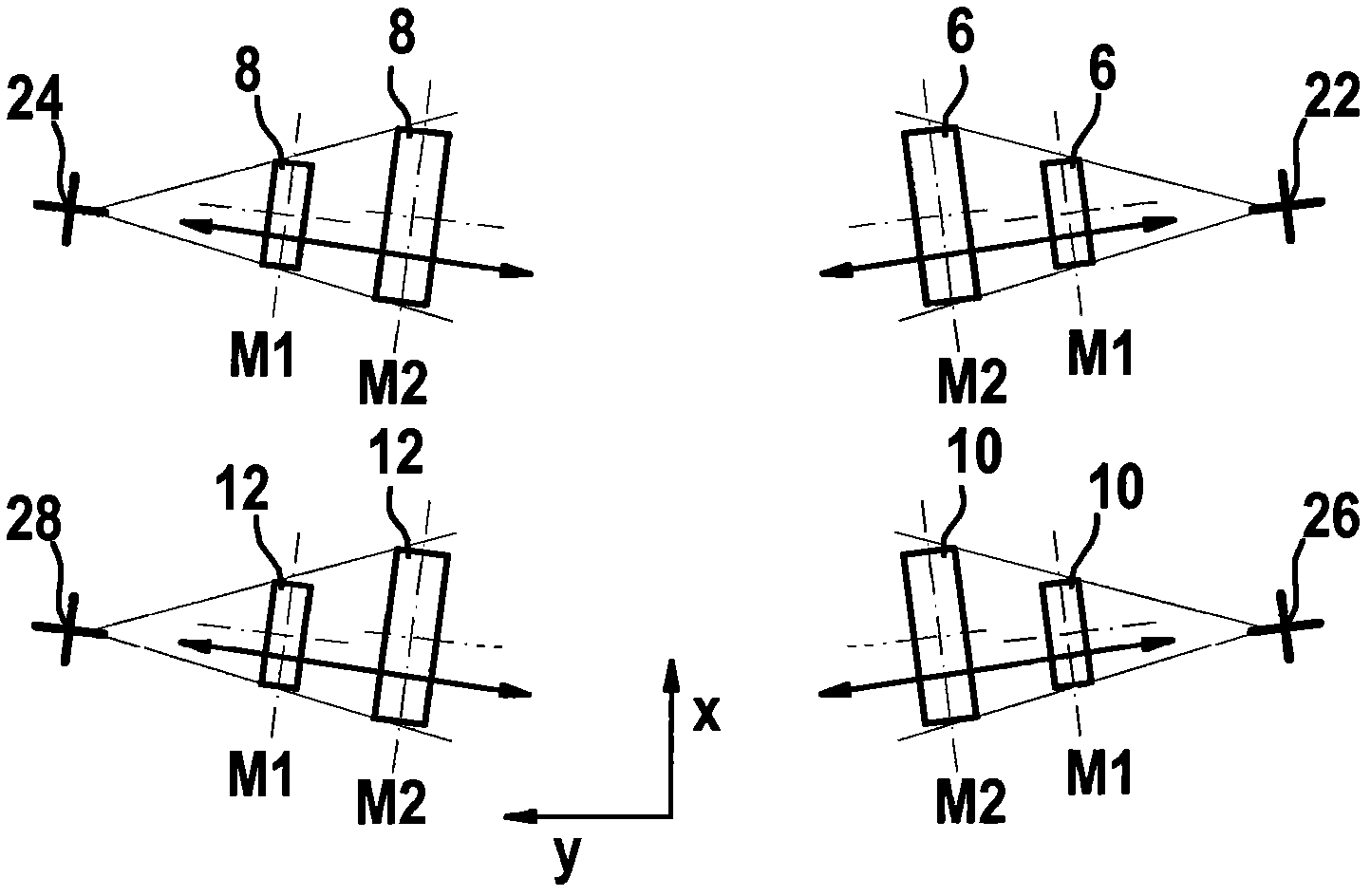

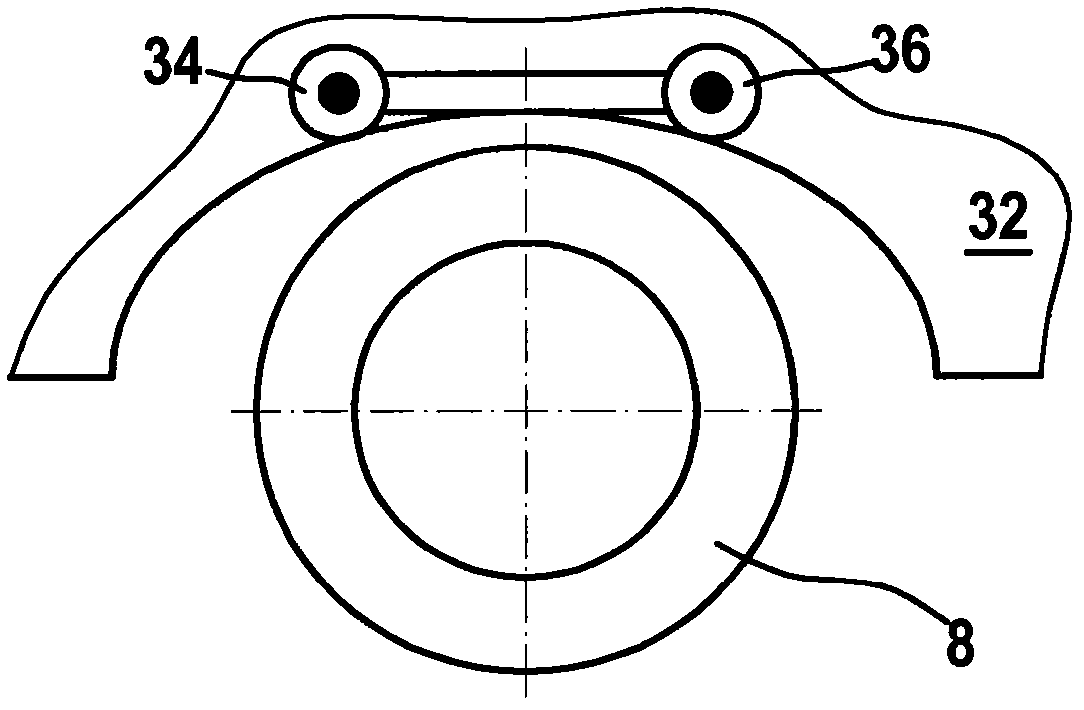

[0031] The device has four measuring heads 2 , 4 , 14 , 16 which are always arranged opposite each other in pairs on both sides of a motor vehicle 1 . Measuring heads 2 , 4 , 14 , 16 each have a monocular camera device 22 , 24 , 26 , 28 on their side facing motor vehicle 1 , which form, for example, cameras. The position of measuring heads 2 , 4 , 14 , 16 in the coordinate system of the measuring location is known and does not change during the measurement.

[0032] Motor vehicle 1 has four wheels 6, 8, 10, 12 and is arranged between measuring heads 2, 4, 14, 16 in such a way that each wheel 6, 8, 10, 12 is positioned on a camera device 22, 24, 26, 28 in view. Measuring heads 2 , 4 , 14 , 16 are connected via data lines 30 to an evaluation device for evaluating the data received and determined by measuring heads 2 , 4 , 14 , 16 . The evaluation device 18 is connected to a display 20 for displaying the measurement results. In addition, the evaluation device 18 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com