Assembly of twisted insulated electric wires

A component and twisting technology, which is applied in the direction of insulated cables, electrical components, insulated conductors, etc., can solve problems such as difficult separation of insulated electrical conductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] For brevity, the same elements have been denoted by the same reference numerals. Likewise, the main elements for understanding the present invention have been schematically shown, but not drawn to scale.

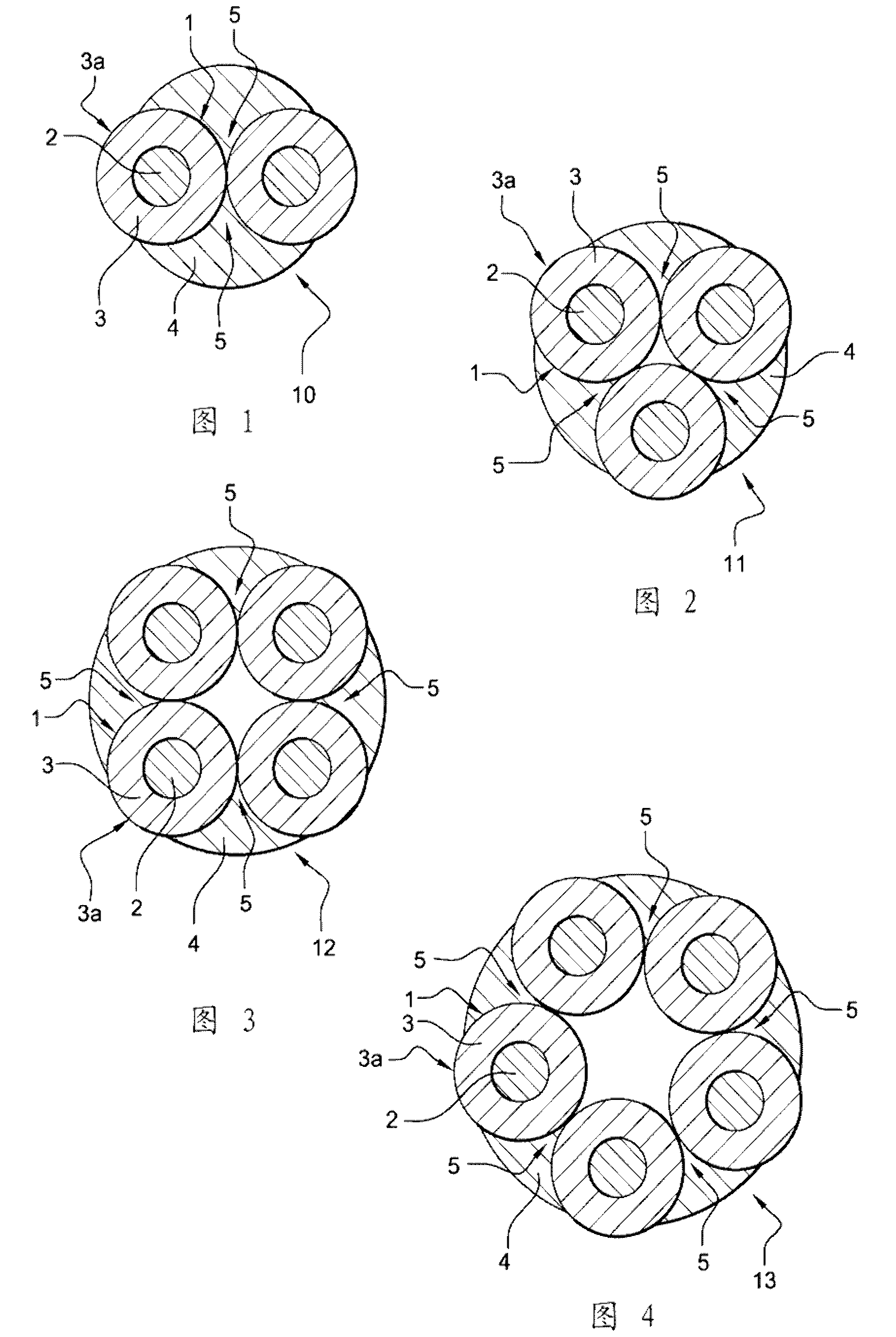

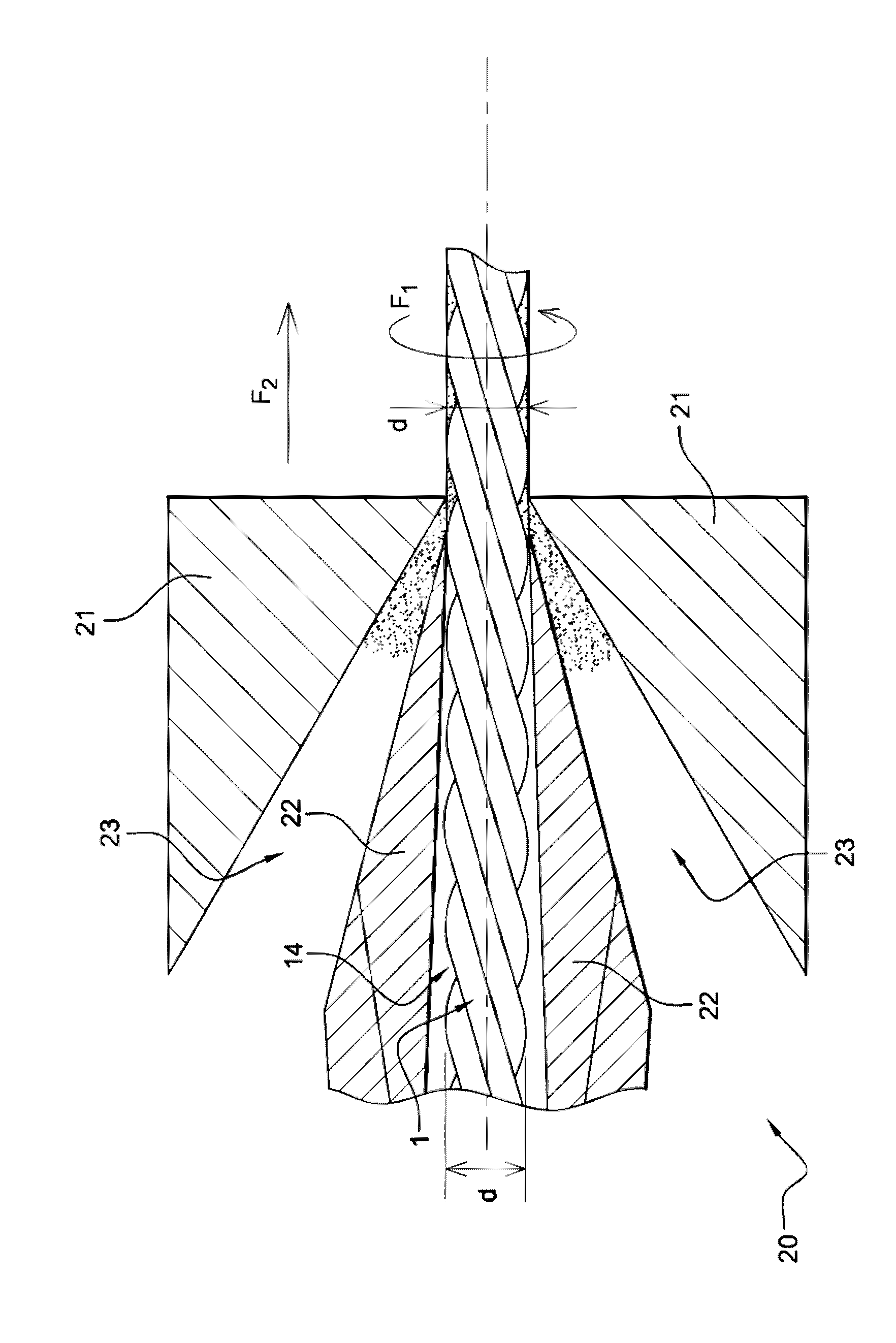

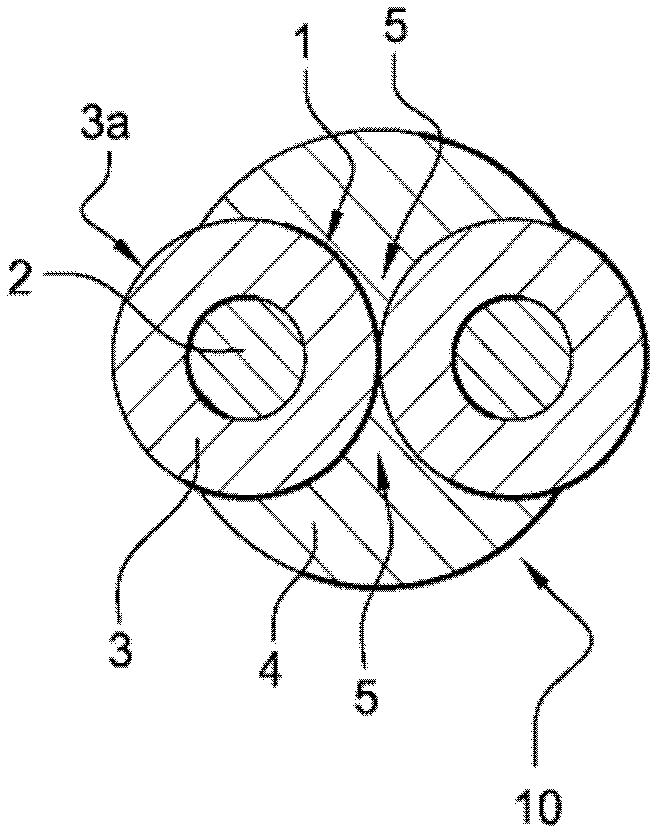

[0037] figure 1 An assembly 10 of two insulated wires 1 is shown, each insulated wire 1 comprising a central conductive core 2 surrounded by an insulating material 3. The two insulated wires are in contact with each other and twisted together. The thermoplastic holding material 4 is continuously extruded and deposited in the outer groove 5 formed between the two insulated wires in order to bond them together. The thermoplastic holding material fills the outer groove 5 so that the outer diameter of the circular cross section of the inscribed thermoplastic holding material is smaller than the outer diameter of the circular cross section of the inscribed twisted bundle. In this way, the thermoplastic holding material does not completely cover the twisted strands, but a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com