Clamping equipment for efficient drilling

A clamping and equipment technology, applied in drilling/drilling equipment, metal processing equipment, components of boring machine/drilling machine, etc., can solve the problems of low processing efficiency, low dimensional accuracy of workpiece, high labor intensity of workers, etc. The qualification rate of products, the effect of reducing labor difficulty and saving clamping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

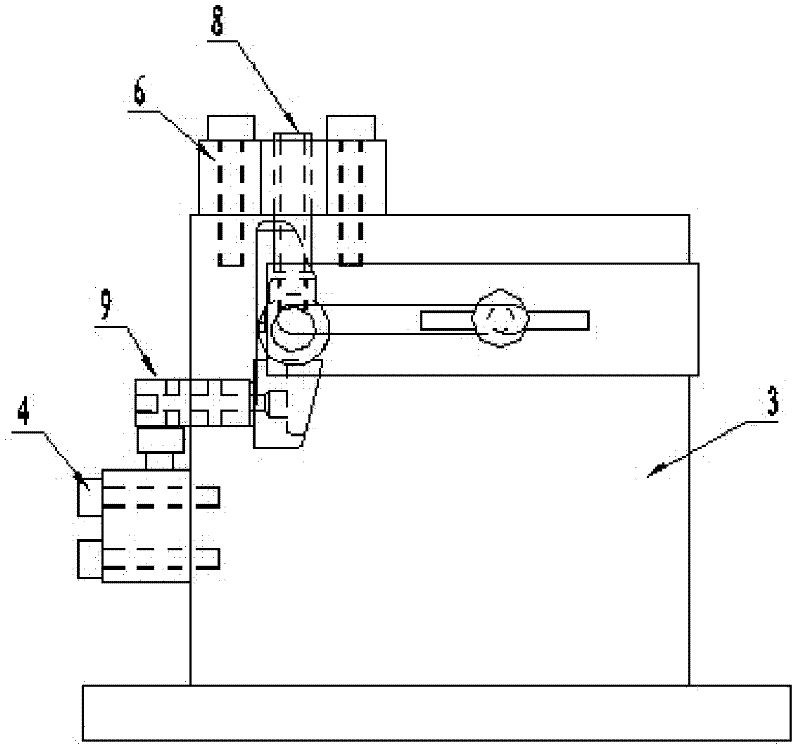

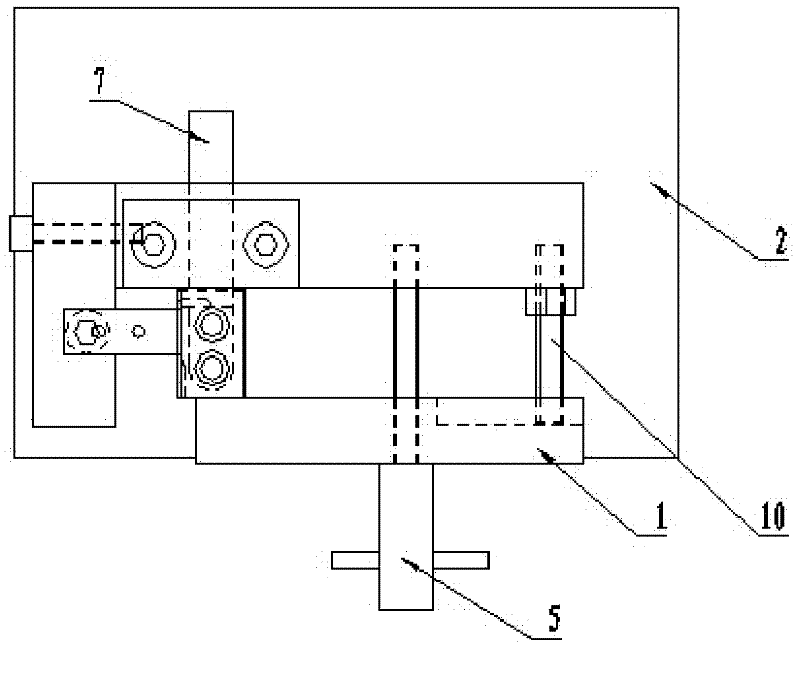

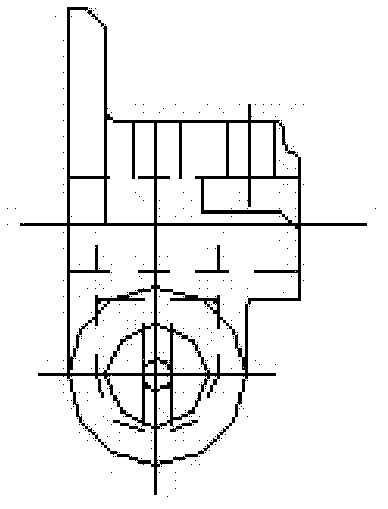

[0020] A clamping device for high-efficiency drilling, including a backing plate 2 and a stopper 3, the stopper is fixed vertically on the backing plate, a drill sleeve bracket 6 is installed on the upper end surface of the stopper, and two Drill sleeve 8, the drill sleeve is made of high-quality white steel material with good wear resistance.

[0021] A positioning rod 7 is inserted on the block below the drill sleeve support, and the two ends of the positioning rod extend to the outside of the front end face and the rear end face of the block respectively, and the positioning rod can be inserted in the through hole of the workpiece 9 to start to the role of positioning the workpiece. A positioning platform 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com