A servo pressing mechanism

A pressing mechanism and servo motor technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low positioning accuracy and inability to accurately control the pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

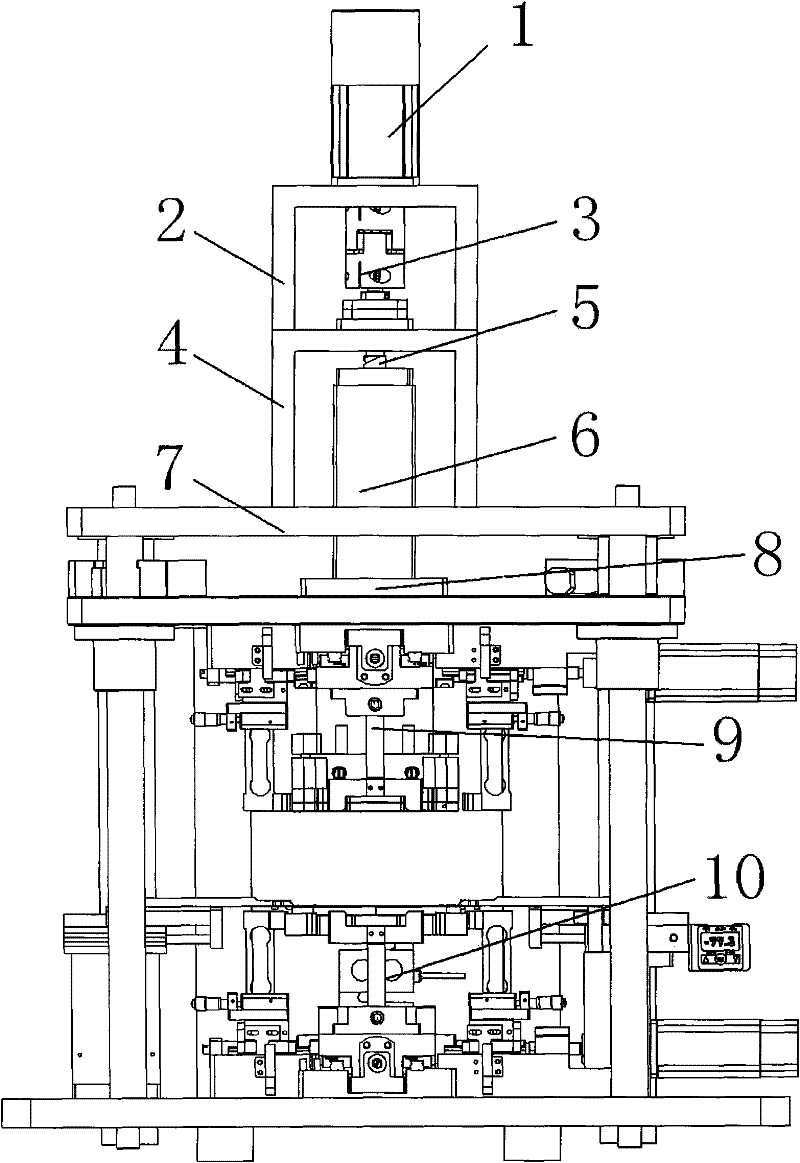

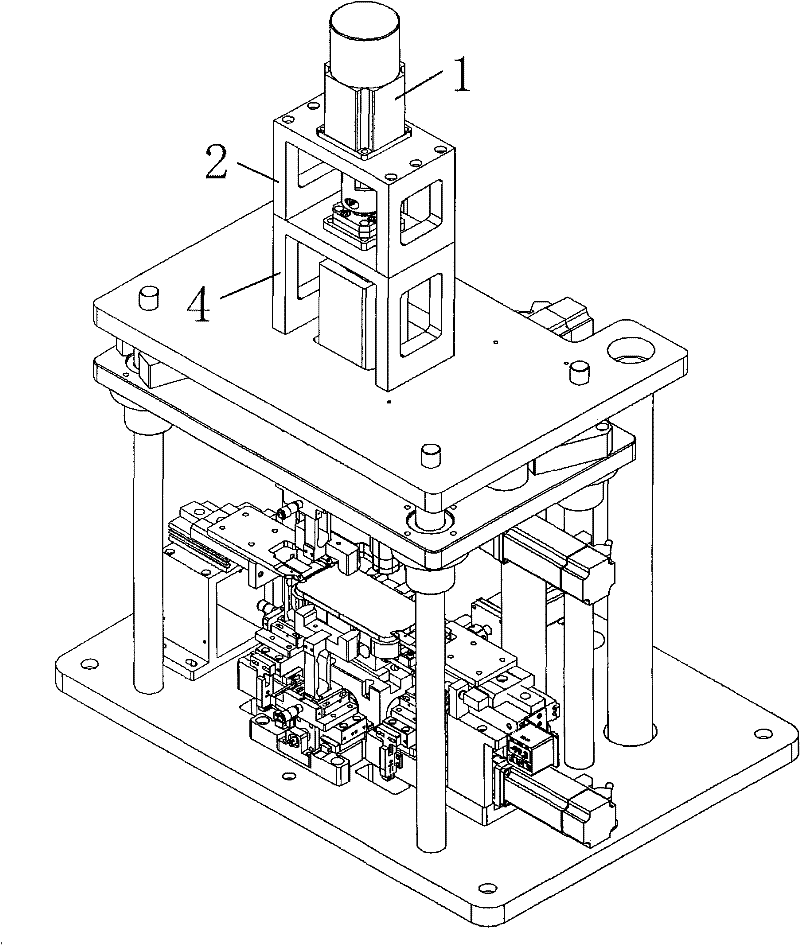

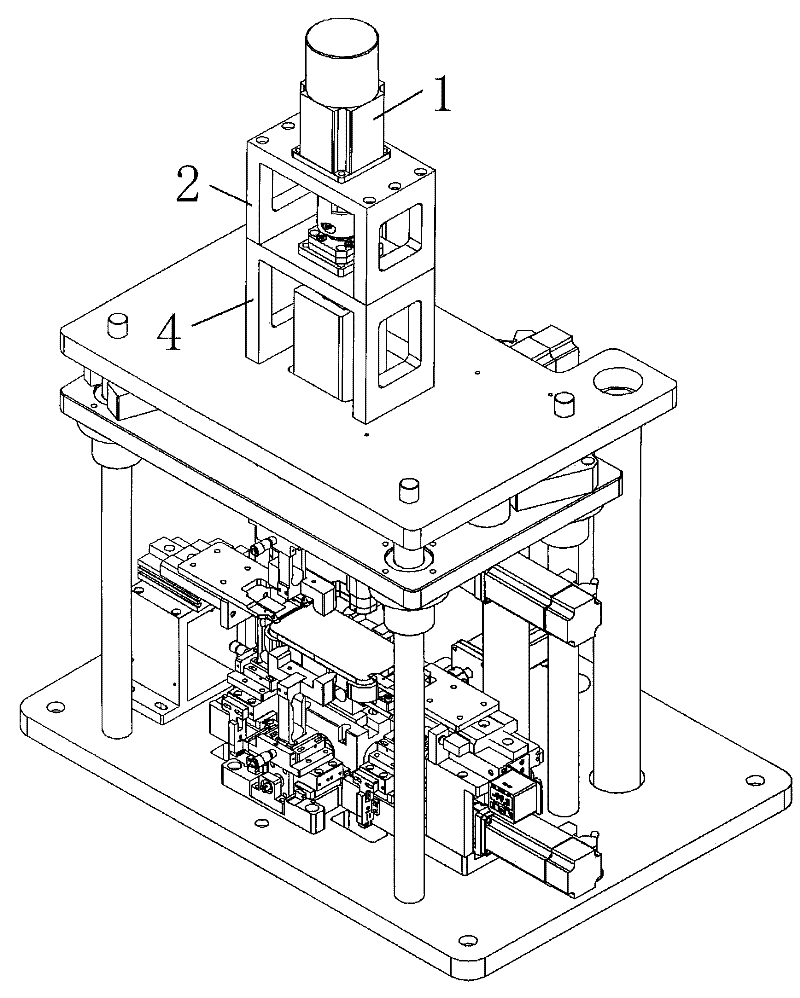

[0014] Examples, see attached figure 1 , 2 ; A servo pressing mechanism has a motor fixing seat 2 and a lead screw fixing seat 4, and the motor fixing seat 2 is fixed on the upper surface of the lead screw fixing seat 4; it can be fixed by welding or screwed by screws / bolts Fixed, there is a servo motor 1 on the motor fixing base 2, the servo motor 1 is fixedly connected with the ball screw 5 fixed on the screw fixing base 4; the slider 6 on the ball screw 5 and the upper cover carrier 9 The connecting block 8 is fixedly connected.

[0015] The servo motor 1 is connected with the ball screw 5 through a coupling 3 . When in use, the whole mechanism is fixed on the upper cover fixing plate 7 of the pressing machine through the screw fixing seat 4. The upper cover fixing plate has an opening that allows the ball screw to pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com