A profile heating device

A technology for heating equipment and profiles, applied in the field of metallurgy, can solve the problems of poor continuity and insufficient uniformity of workpieces, and achieve the effects of easy control of moving speed, stable transmission and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

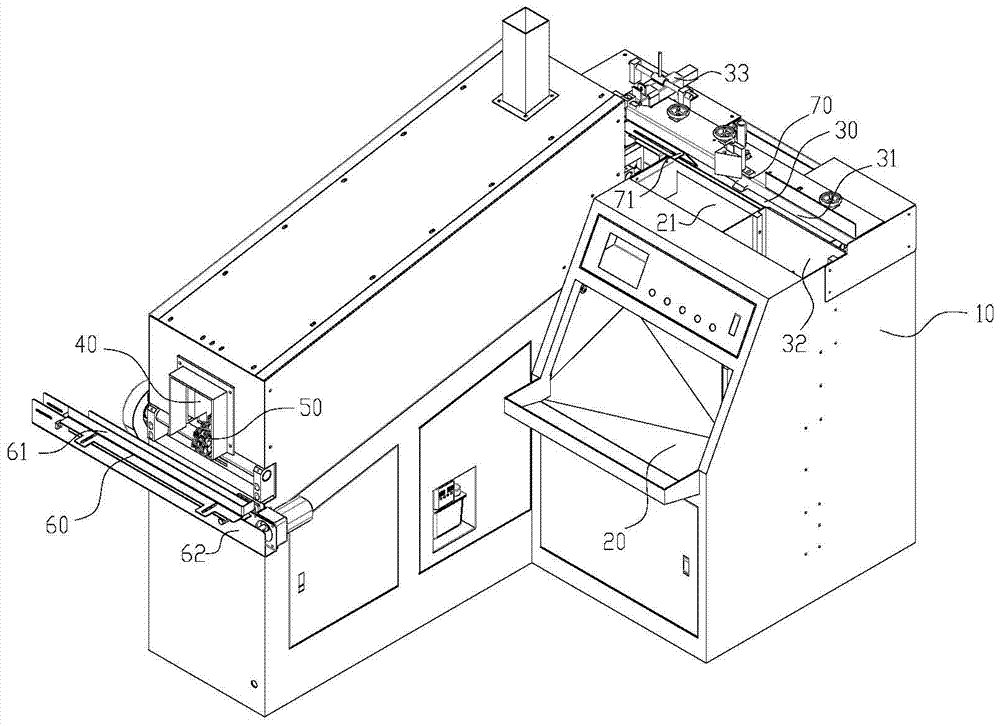

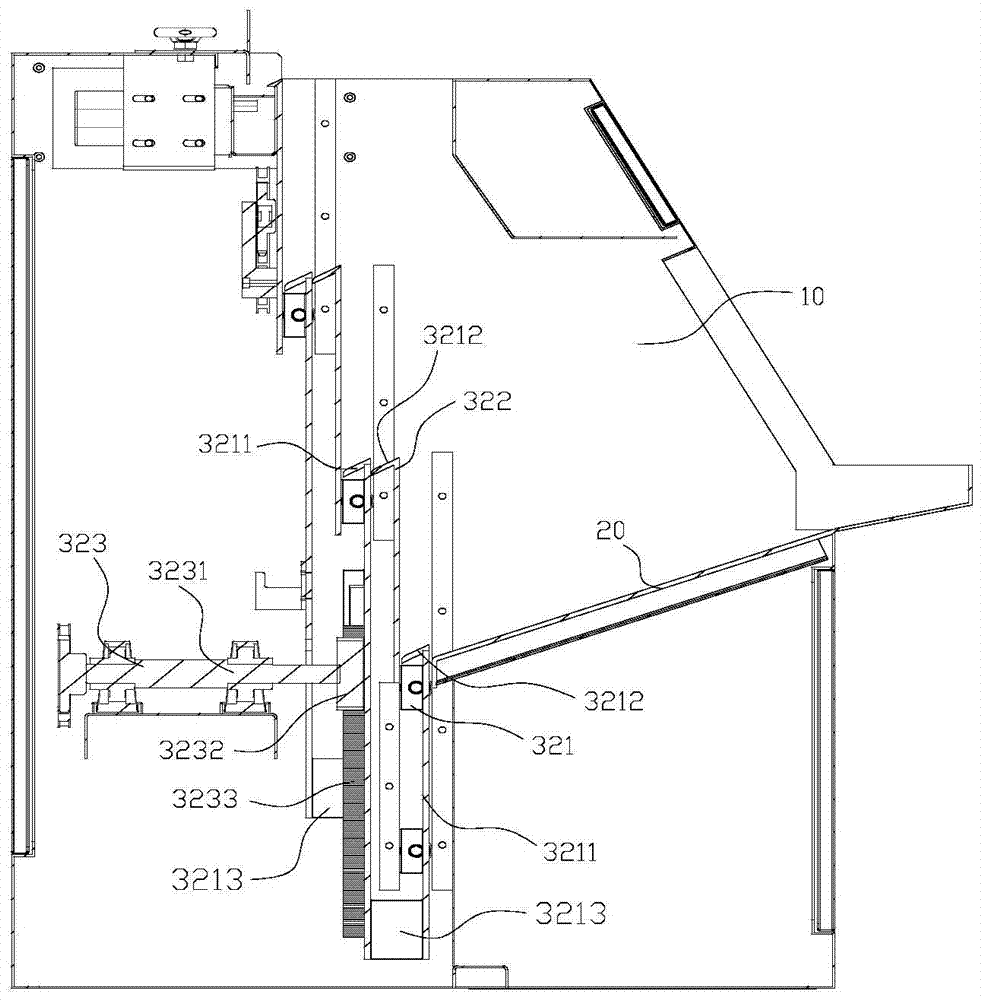

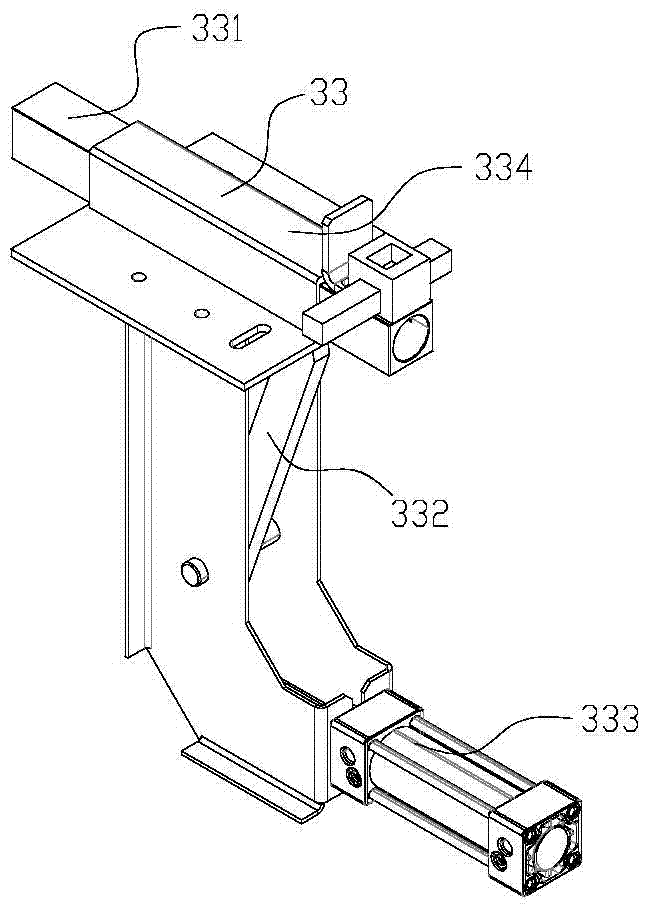

[0034] Examples, see Figure 1 to Figure 5 Shown: a profile heating equipment, including: a body 10, a hopper 20 is installed on the body 10, a large number of cylindrical workpieces are placed in the hopper 20, and the workpieces can also be other elongated workpieces; a conveying mechanism 30, The conveying mechanism 30 is arranged on the body 10 and can transport the workpiece in the hopper 20; the heating channel 40, the heating channel 40 is installed on the body 10, and the transmission chain 50 and the sprocket wheel 52 that drives the transmission chain 50 to rotate are installed in the heating channel 40 , the transmission chain 50 is composed of several sprockets 51 and hinge pins that link the sprockets 51 to form a closed loop, and a slot 515 is formed between two adjacent sprockets 51; the conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com