Machining device and method of leaking stoppage fiber particles

A processing device and fiber particle technology, applied in the field of mechanical processing, can solve the problems of low efficiency of manual winding, high production cost, poor quality control, etc., and achieve the effect of automatic winding, good clamping effect and easy moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

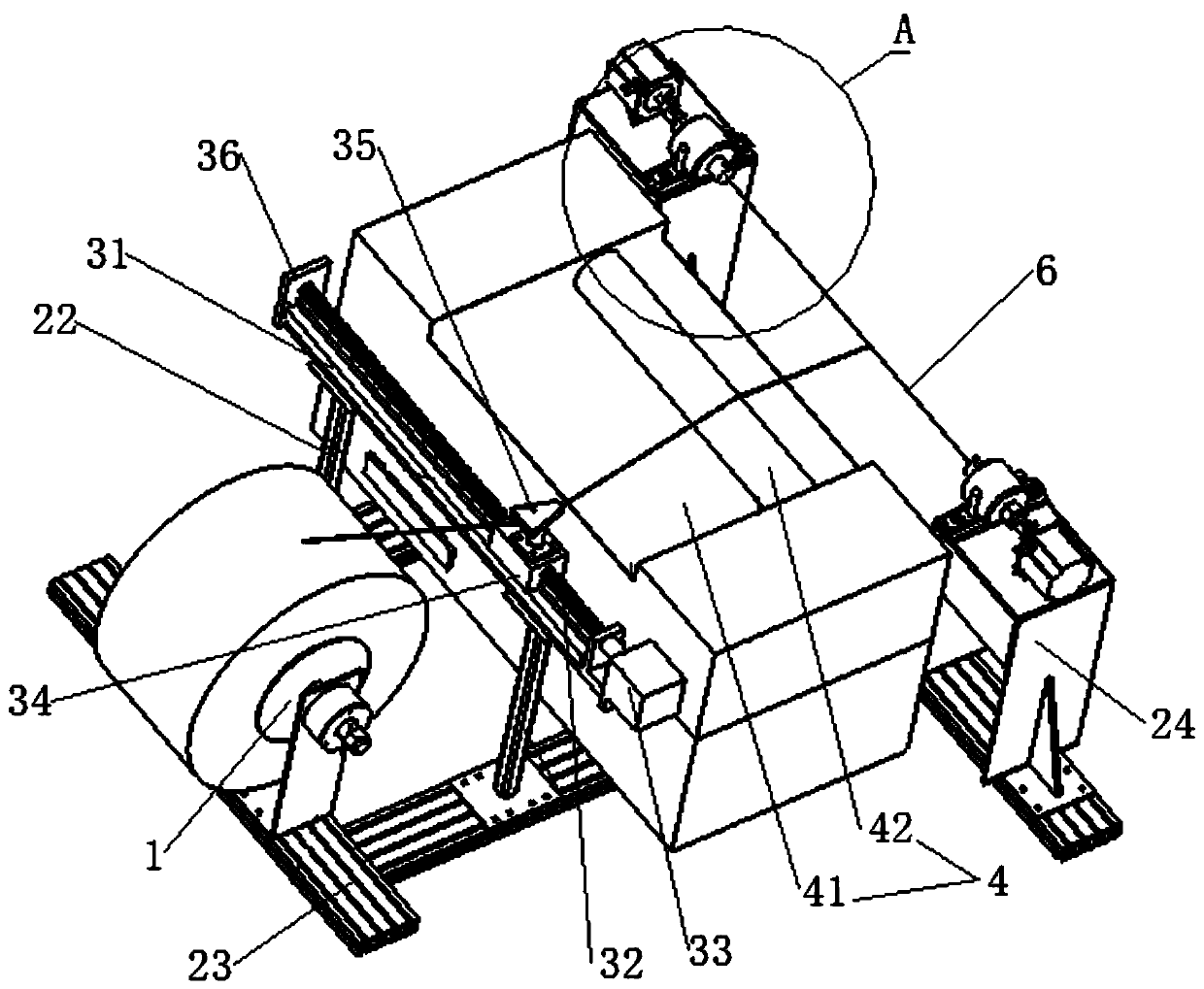

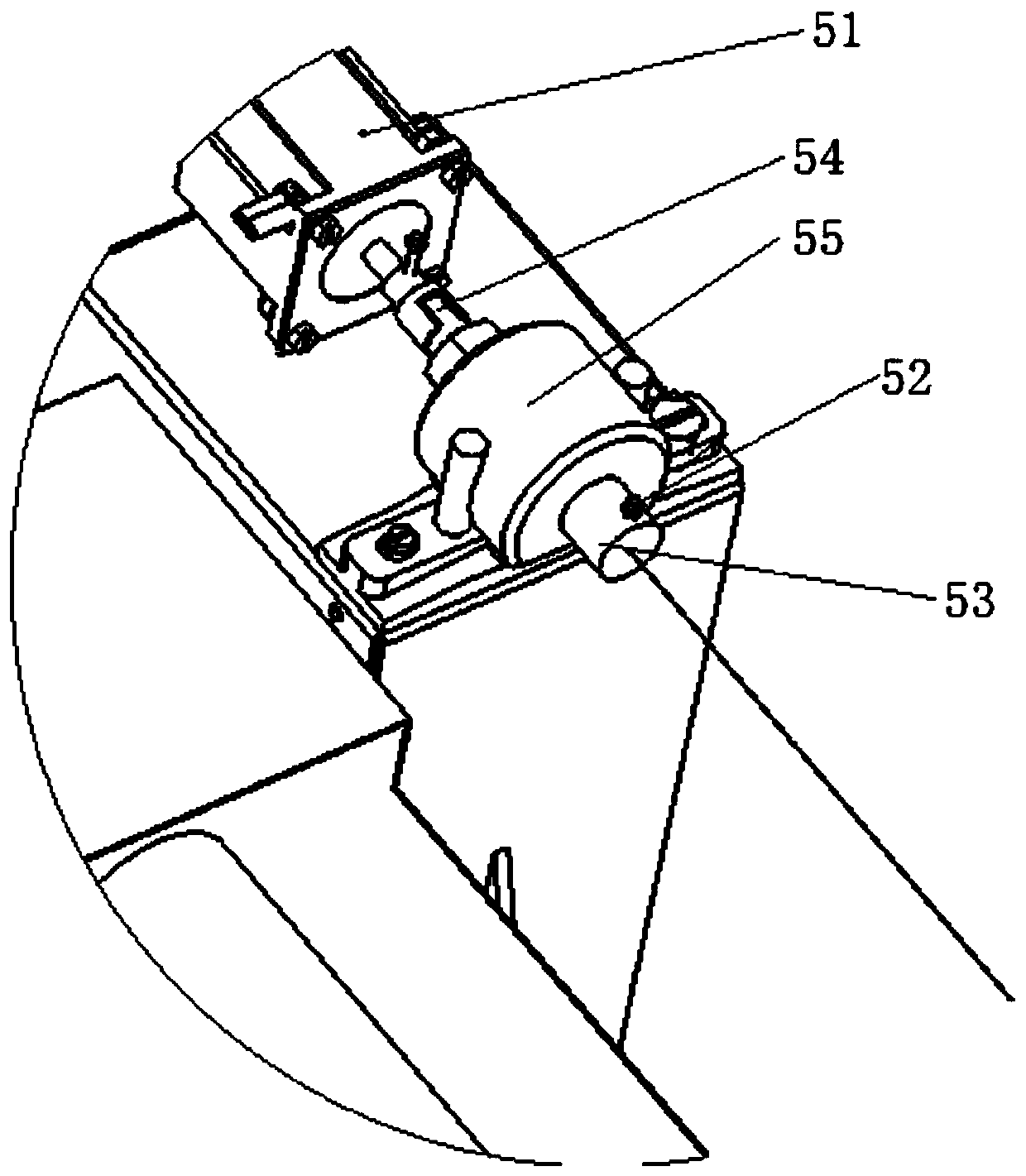

[0072] like figure 1 As shown, a processing device for plugging fiber particles includes a support frame, and an on-line mechanism 1 connected to the support frame, a glue hanging mechanism 4, a wiring mechanism and a rotating clamping mechanism, and the glue hanging mechanism 4 and the wiring mechanism are all provided with Between the upper thread mechanism 1 and the rotary clamping mechanism.

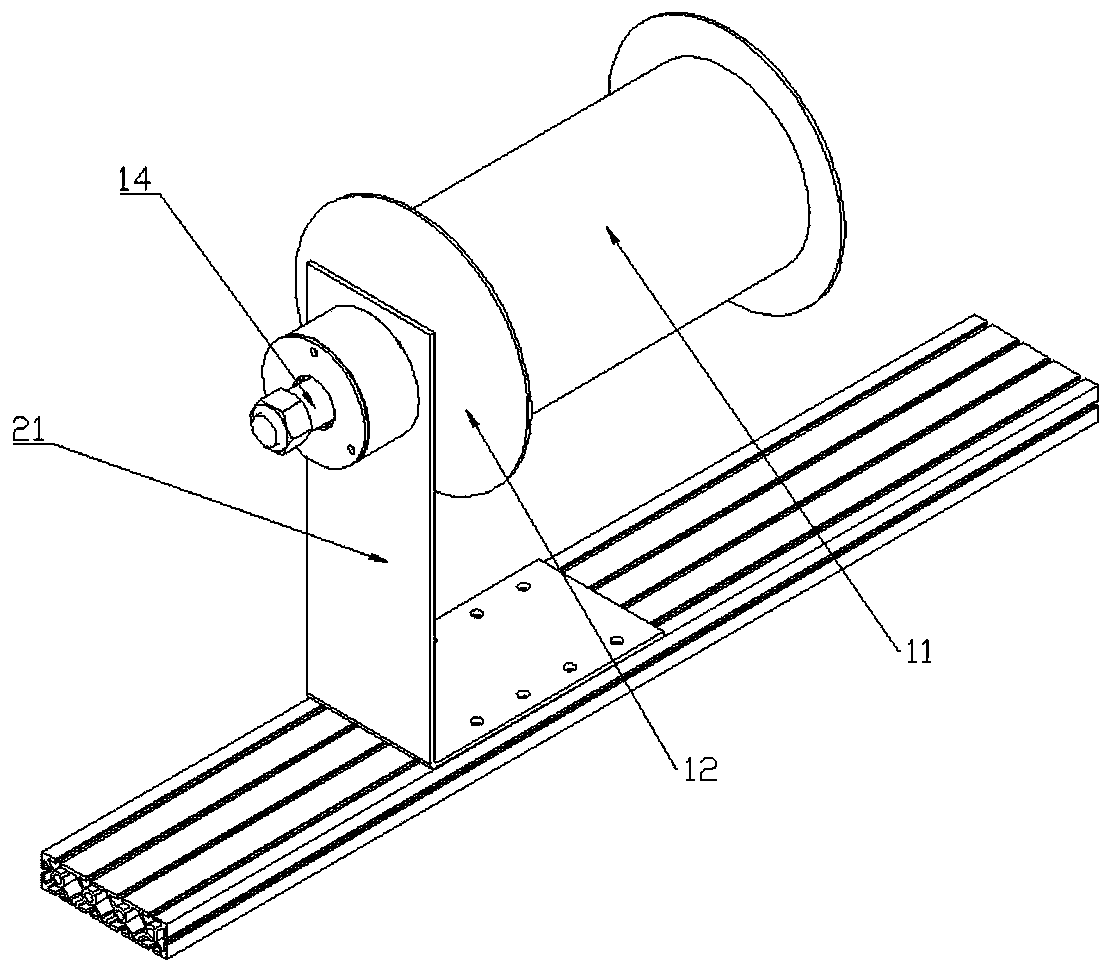

[0073] On-line mechanism 1, the on-line mechanism 1 is used to place fiber coils wound by fiber threads.

[0074] The rotating clamping mechanism is used to drive the steel wire 6 to rotate, and to wind the fiber thread around the steel wire 6 .

[0075] Wiring mechanism, the wiring mechanism is arranged between the glue hanging mechanism 4 and the threading mechanism 1, and the wiring mechanism is used to control the movement of the fiber wire along the axis of the steel wire 6, so that the fiber wire is evenly wound on the steel wire 6.

[0076] A glue-hanging mechanism 4, the gl...

Embodiment 2

[0079] like Figure 1-3 Shown, a kind of processing method of the processing device of plugging fiber particle, comprises the following steps:

[0080] Step A: Wrap the fiber wire around the steel wire 6 .

[0081] Step B: Fix the fiber thread and the steel wire 6 .

[0082] Step C: cutting the shaped fiber strands and steel wires 6 into sections to form granules.

Embodiment 3

[0084] like Figure 1-3 As shown, a processing device for plugging fiber particles includes a support frame, and an on-line mechanism 1 connected to the support frame, a glue hanging mechanism 4, a wiring mechanism and a rotating clamping mechanism, and the glue hanging mechanism 4 and the wiring mechanism are all provided with Between the upper thread mechanism 1 and the rotary clamping mechanism.

[0085] On-line mechanism 1, the on-line mechanism 1 is used to place fiber coils wound by fiber threads.

[0086] The rotating clamping mechanism is used to drive the steel wire 6 to rotate, and to wind the fiber thread around the steel wire 6 .

[0087] Wiring mechanism, the wiring mechanism is arranged between the glue hanging mechanism 4 and the threading mechanism 1, and the wiring mechanism is used to control the movement of the fiber wire along the axis of the steel wire 6, so that the fiber wire is evenly wound on the steel wire 6.

[0088] A glue-hanging mechanism 4, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com