Bioflocculant fermentation method with mycelium pellet as vector

A technology for fermentation organisms and mycelial balls is applied in the field of fermentation biological flocculants, which can solve the problems of being unsuitable for large-scale industrial fermentation production, low production efficiency and high production cost, reducing the chance of contamination by miscellaneous bacteria, improving production efficiency and flocculation. rate stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

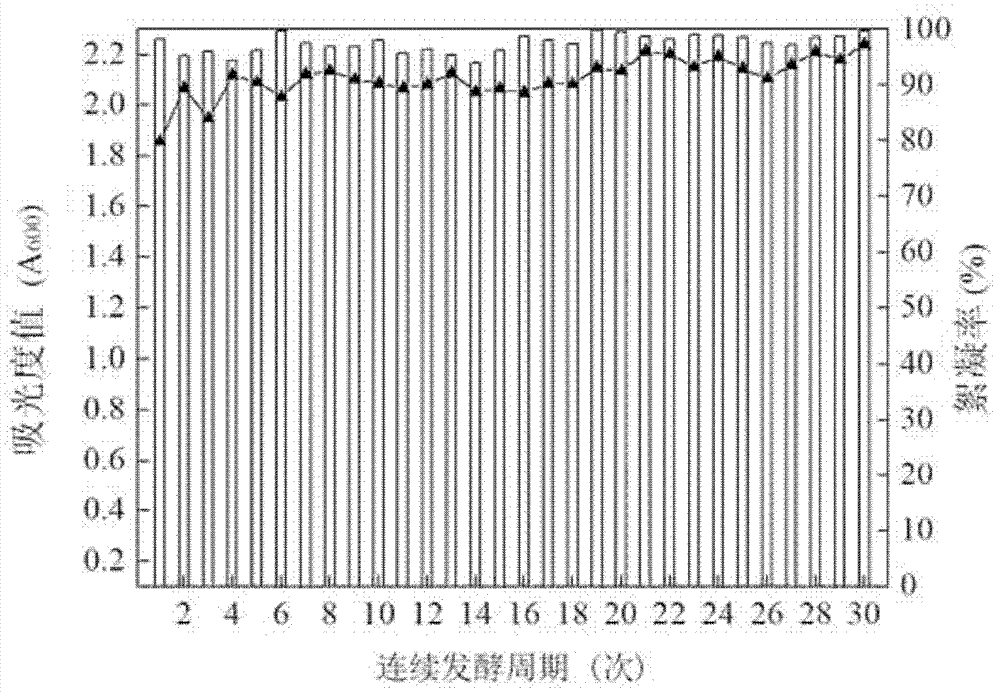

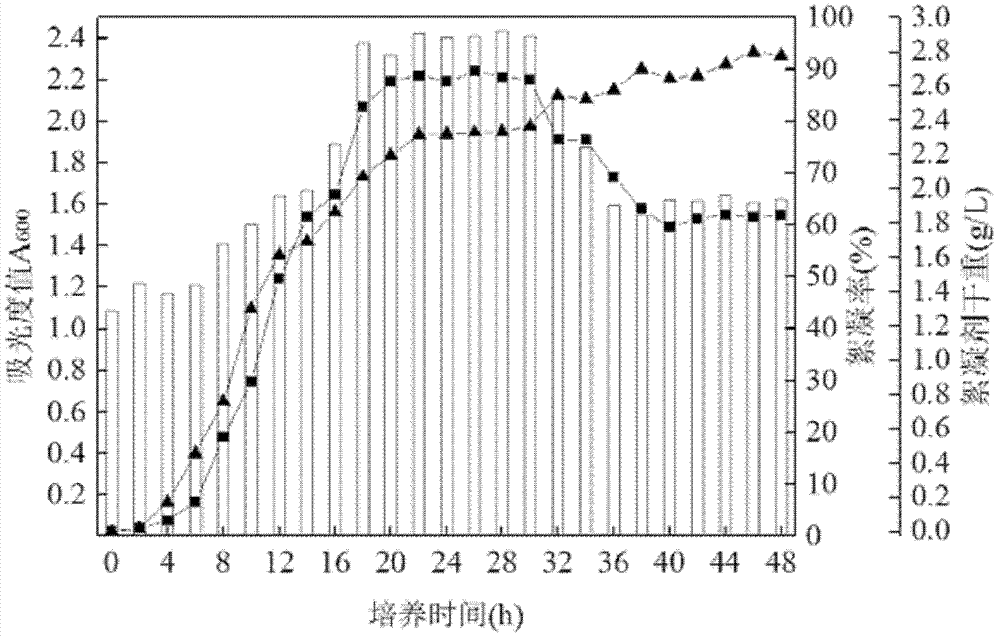

[0009] Specific embodiment 1: In this embodiment, the method for fermenting biological flocculants with mycelium balls as a carrier is carried out in the following steps: 1. After mixing Rhizobium radiata and Bacillus sphaericus in a volume ratio of 1:1, inoculate it into a 100mL flocculation-producing container In a 250mL Erlenmeyer flask with bacterial culture medium, place it in a shaker with a temperature of 20-30°C and a rotation speed of 120-160r / min for 18-30 hours to obtain the floc-producing fungus seed liquid; 2. The spore suspension of Aspergillus niger Inoculate into a 250mL Erlenmeyer flask containing 100mL of mycelium ball medium, place it in a shaker with a temperature of 28-32°C and a rotation speed of 140r / min and cultivate it for 1-7 days to obtain mature mycelium balls; 3. Mature Rinse mycelium balls with sterilized phosphate solution and add them to a 250mL Erlenmeyer flask containing 100mL flocculogen culture medium, then add flocculogen seed liquid at a vo...

specific Embodiment approach 2

[0015] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, it is placed in a shaker with a temperature of 20° C. and a rotation speed of 160 r / min for 30 hours to obtain flocculogen seed liquid. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0016] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 1, it is placed in a shaker with a temperature of 30° C. and a rotation speed of 120 r / min for 18 hours to obtain flocculogen seed liquid. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com