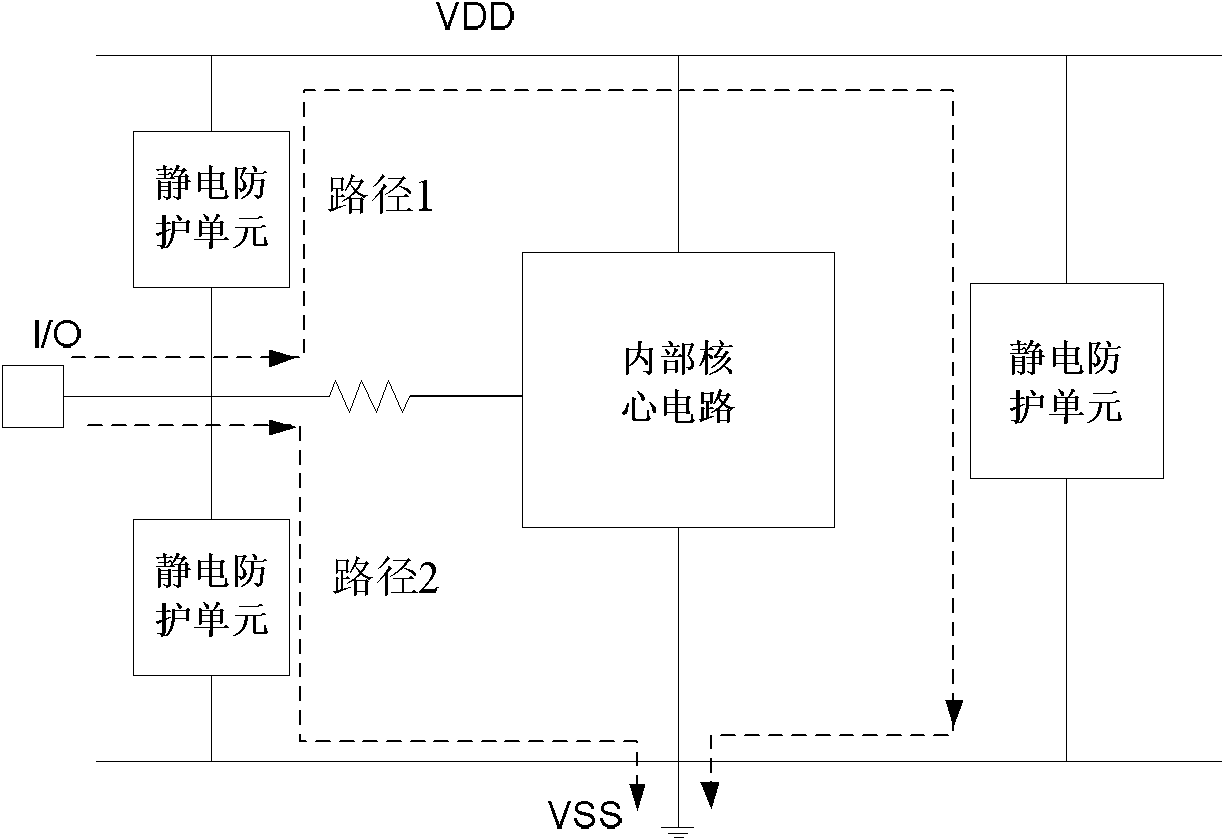

A Reverse Diode Trigger SCR for Electrostatic Protection

A reverse diode, electrostatic protection technology, applied in the direction of diodes, circuits, electrical components, etc., can solve the problems of large energy, short time, damage to circuit devices, etc., and achieve the effects of uniform current, rapid response, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

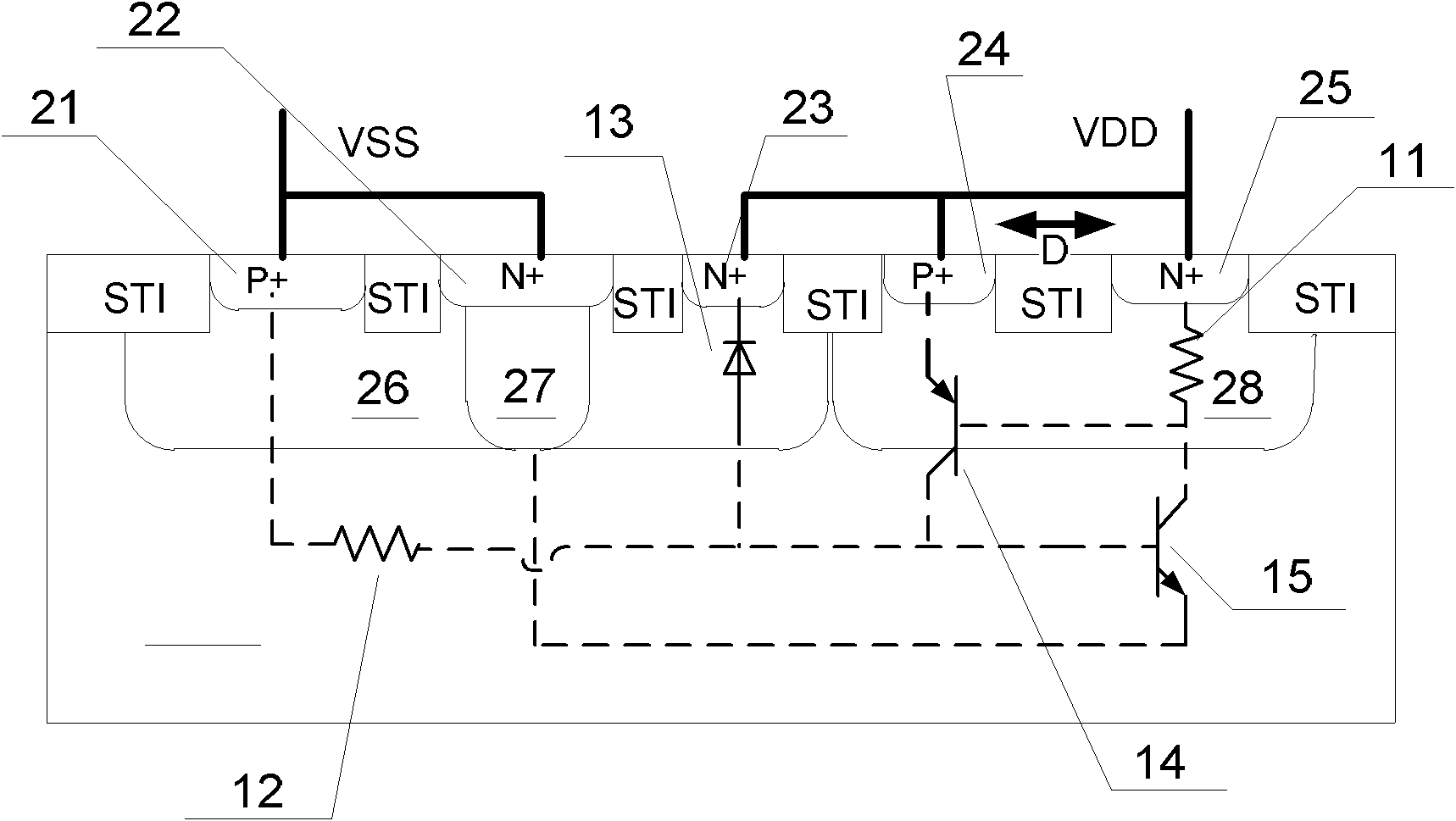

[0019] The structures of P well, N well, N+ active injection region and P+ active injection region in the present invention can be realized by using the existing standard CMOS integrated circuit manufacturing process.

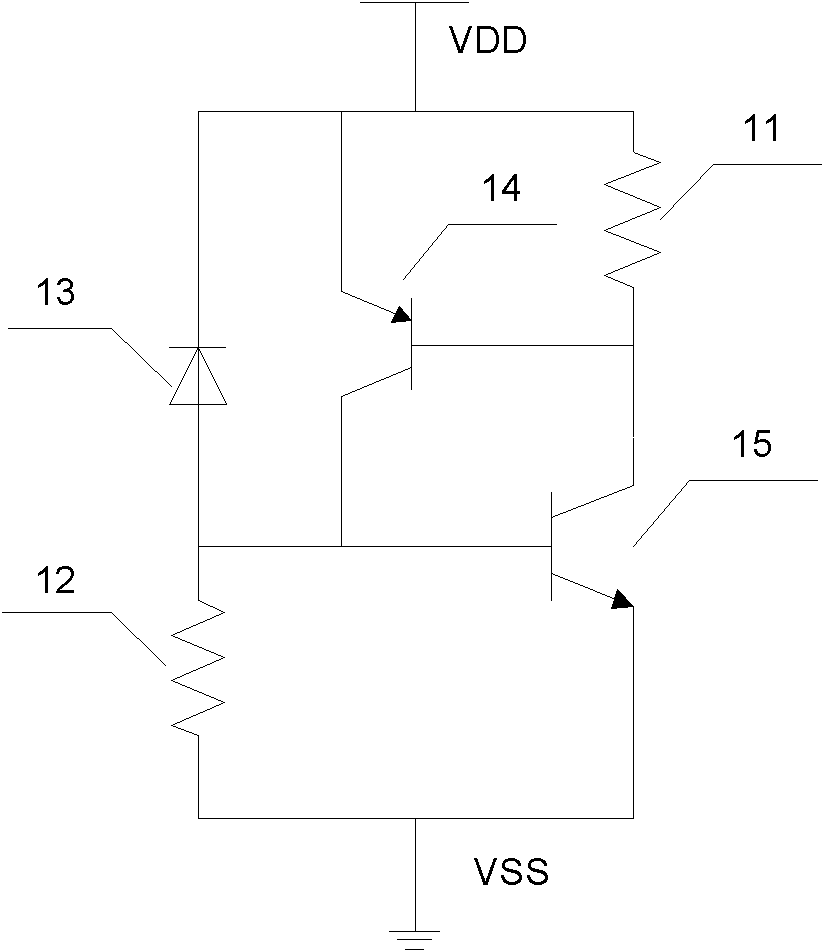

[0020] The equivalent circuit diagram of the present invention sees figure 2 , comprising a first bipolar transistor PNP14, a second bipolar transistor NPN15 and a reverse diode 13, wherein the emitter of the first bipolar transistor PNP14 is connected to the power supply terminal, and the base is connected to the power supply terminal through an N-well resistor 11; the second bipolar transistor PNP14 is connected to the power supply terminal; The emitter of the two bipolar transistors NPN15 is grounded, and the base is grounded through the P well and the P substrate resistor 12; the base of the first bipolar transistor PNP14 is connected to the collector of the second bipolar transistor NPN15, and the second bipolar transistor NPN15 is connected to the base. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com