Composite electrolyte for colloidal lead-acid battery

A lead-acid battery and electrolyte technology, used in lead-acid batteries and other directions, can solve the problems of electrical performance not meeting the promulgated indicators, low capacity and starting discharge performance, and obvious solid-liquid interface, etc. rate increase, improve the effect of small capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

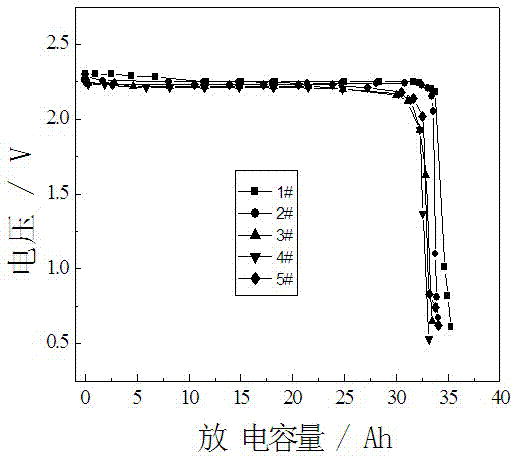

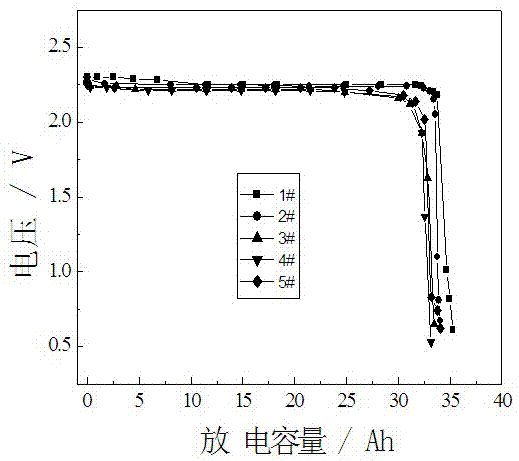

Image

Examples

Embodiment Construction

[0008] Weigh silicon dioxide, sulfate, polyacrylamide (PAM) and sodium carboxymethyl cellulose (CMC) with a particle size of 5-20 nm in proportion, add deionized water to the mixed solution and stir statically. Slowly add 98% concentrated sulfuric acid and sulfate to the mixed solution and carry out ultrasonic dispersion for 10-20 minutes, and leave it for 2 days to make it stable, that is, the colloidal composite electrolyte for lead-acid batteries is made.

[0009] The specific feed composition of each component accounts for the weight percentage (100%) of the total feed:

[0010] Scheme 1 (1#): SiO 2 : 0.2%, Na 2 SO 4 : 0.02%, K 2 SO 4 : 0.1%, MgSO 4 : 0.02%, H 2 SO 4 : 52.62%, polyacrylamide (PAM): 0.1%, sodium carboxymethylcellulose (CMC): 0.01%, La 2 (SO 4 ) 3 : 0.001%, the rest is deionized water.

[0011] Scheme 2 (2#): SiO 2 : 0.3%, Na 2 SO 4 : 0.2%, K 2 SO 4 : 0.04%, MgSO 4 : 0.1%, H 2 SO 4 : 50.26%, polyacrylamide (PAM): 0.03%, sodium carboxymethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com