Fluid-enclosed vibration isolation device

A vibration isolation and fluid technology, which is applied in the direction of shock absorber, shock absorber-spring combination, spring, etc., can solve the problems that the movable plate touches the collision sound easily, produces impact sound, collision, etc., and reduces the number of parts , Avoid collision sound, reduce speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

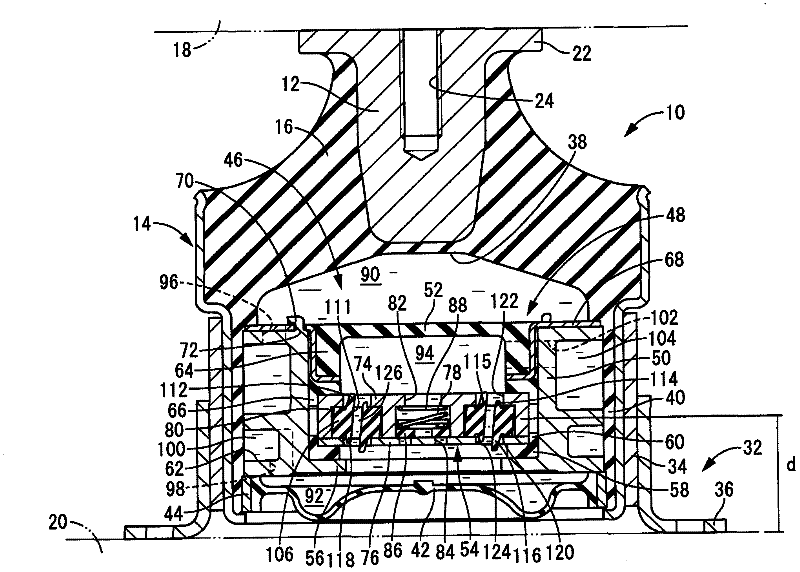

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, in figure 1 In the figure, an automobile engine mount 10 is shown as a first embodiment of a fluid-filled vibration isolator having a structure based on the present invention. The engine mount 10 for an automobile has a structure in which a first mounting member 12 and a second mounting member 14 are connected to each other by a main body rubber elastic body 16 . In addition, the first mounting member 12 is mounted on the power unit 18 , and the second mounting member 14 is mounted on the vehicle body 20 , thereby coupling the power unit 18 to the vehicle body 20 through vibration isolation. In addition, in the following description, the up-down direction means in principle figure 1 in the up and down direction.

[0048] More specifically, the first attachment member 12 has a substantially cylindrical shape and is formed of a highly rigid member made of metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com