Apparatus and method for treating process exhaust gas

A waste gas treatment device and waste gas treatment technology, which are applied in separation methods, chemical instruments and methods, and dispersed particle separation to achieve the effects of slowing down corrosion, reducing corrosion, and being convenient for replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

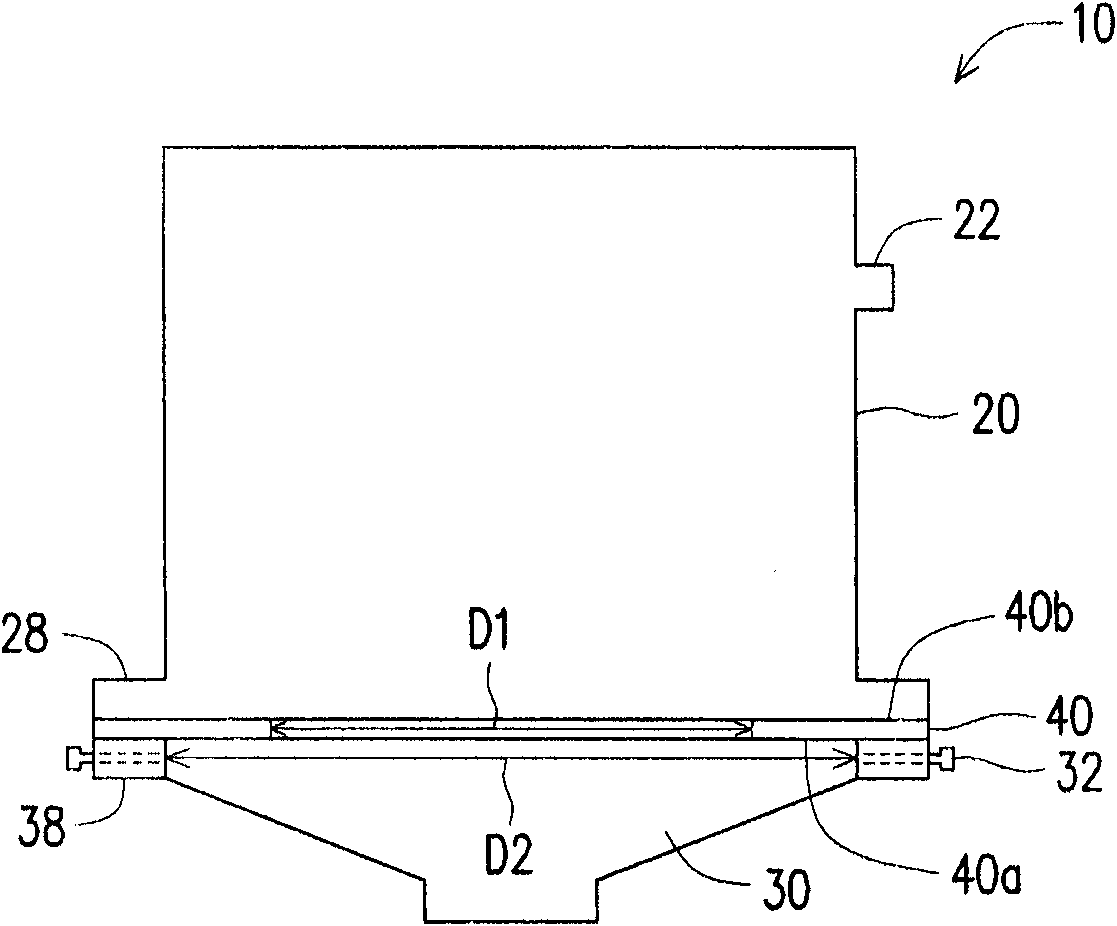

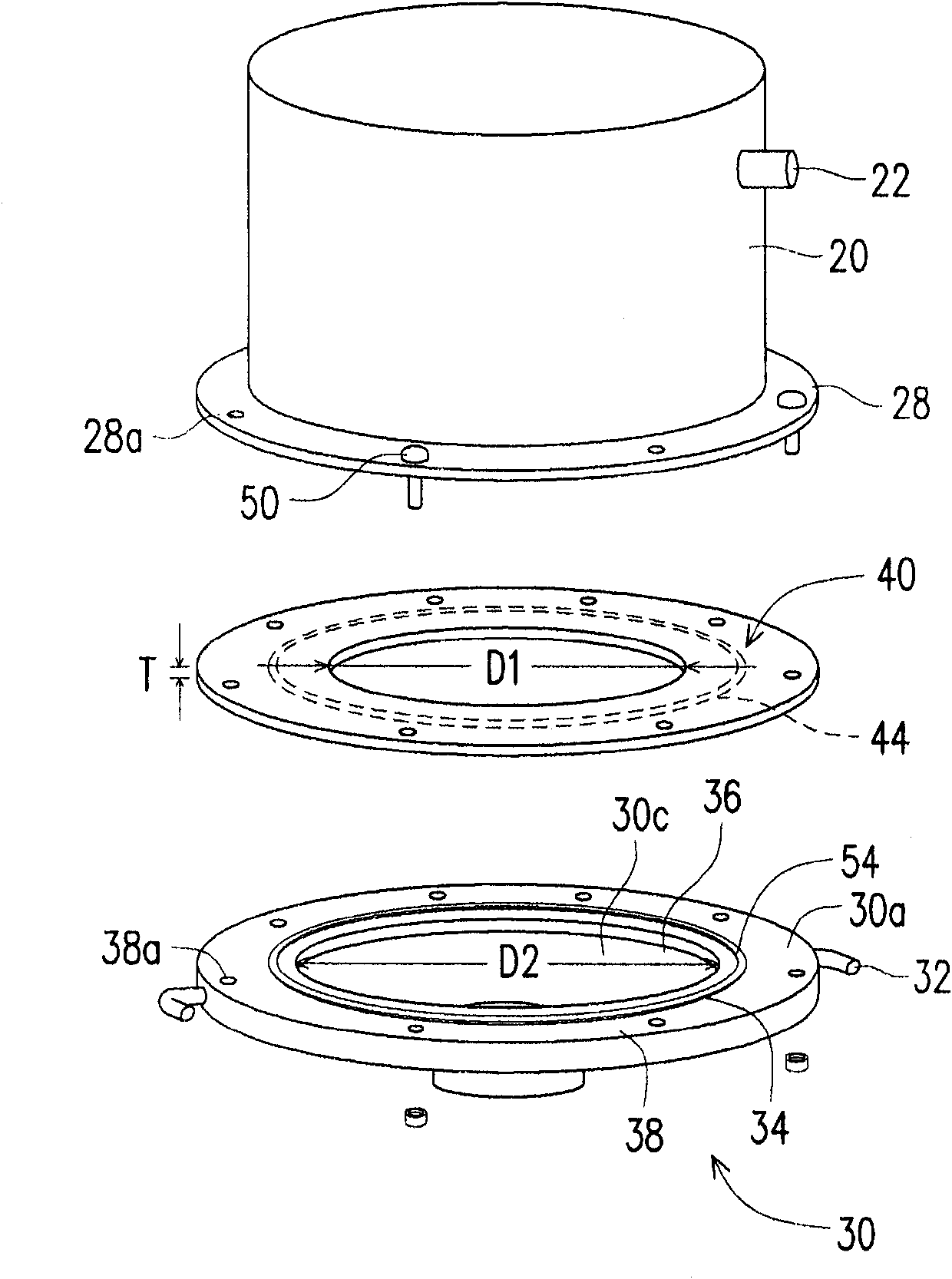

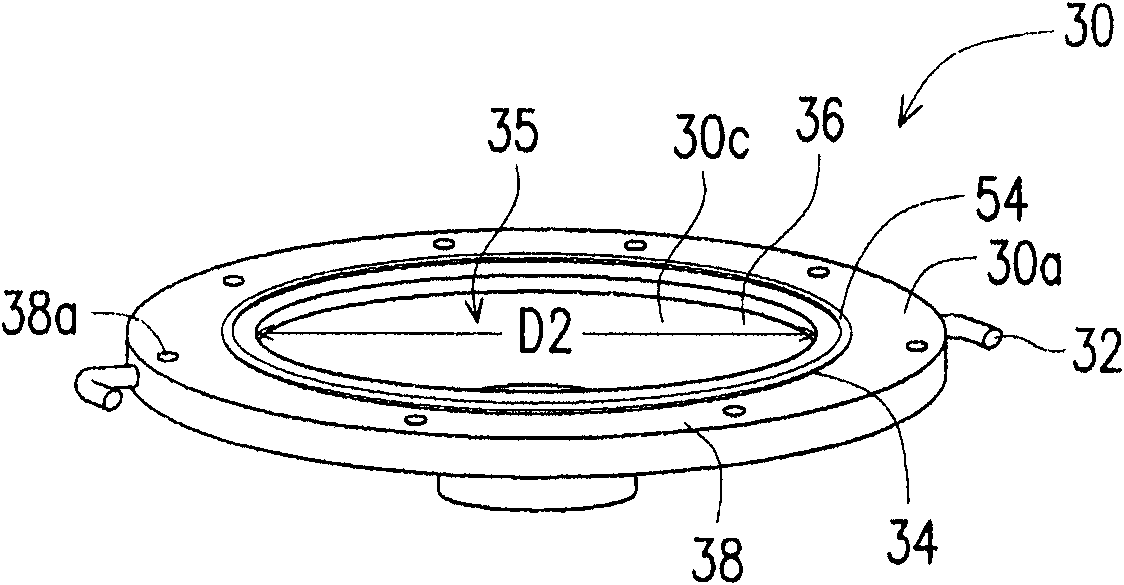

[0049] figure 1 A schematic cross-sectional view of a process waste gas treatment device according to an embodiment of the present invention is shown. figure 2 A schematic disassembly diagram of a process waste gas treatment device according to an embodiment of the present invention is shown. image 3 A schematic diagram showing the funnel of the process waste gas treatment unit. Figure 4 A schematic diagram showing the cap ring on the funnel.

[0050] Please refer to figure 1 , the process waste gas treatment device 10 includes a cavity 20 , a funnel 30 and a top cover ring 40 . The cavity 20 has at least one waste gas inlet 22, which can introduce the process waste gas generated by the process equipment. In the drawings, the exhaust gas inlet 22 is arranged on the side wall of the cavity 20 , but not limited thereto, the exhaust gas inlet 22 can also be arranged at a suitable position according to actual needs, such as above the cavity 20 . The cavity 20 may have a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com