Pneumatic clamping system

A clamping and pneumatic technology, applied in the direction of clamping, positioning device, support, etc., can solve the problems of low efficiency, poor positioning accuracy, unfavorable large-scale processing and production, etc., to change the operation mode, improve the efficiency and accuracy of clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

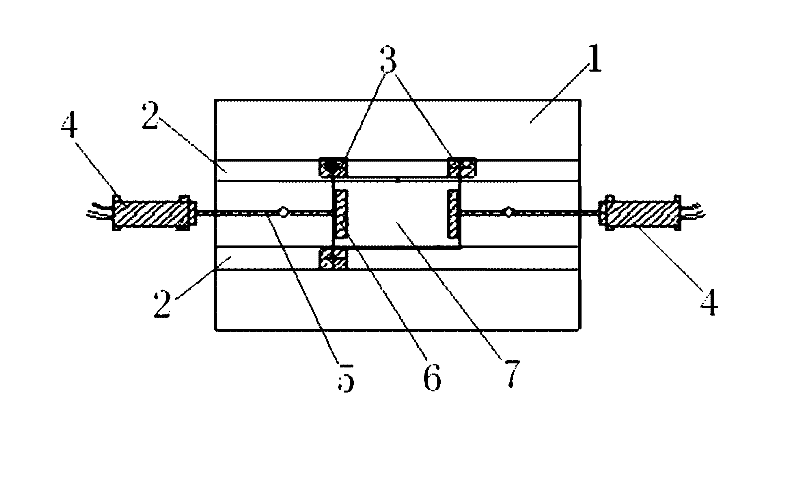

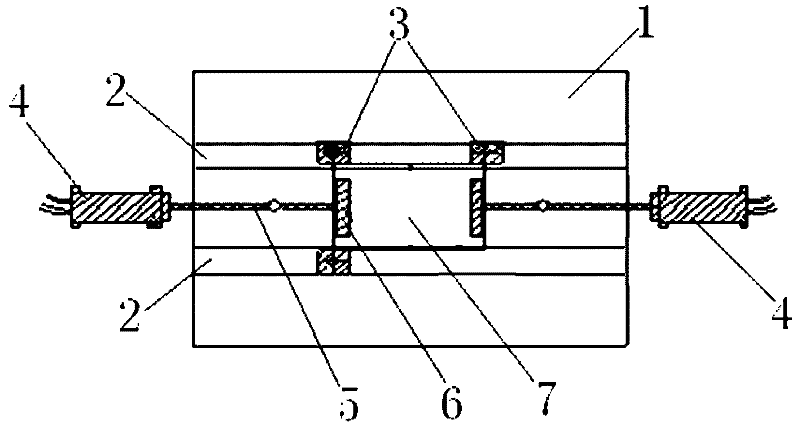

[0012] As shown in the accompanying drawings, the working table 1 of the pneumatic clamping system is provided with positioning grooves 2, and the positioning grooves 2 are distributed up and down, and positioning blocks 3 are arranged in it, and the two sides of the working table 1 between the positioning grooves 2 are provided Cylinder 4, said cylinder 4 is connected with briquetting block 6 through crankshaft 5, in order not to damage the surface of workpiece 7 during processing, said briquetting block 6 is a nylon briquetting block. The workpiece 7 is fixed between the pressure blocks 6 .

[0013] If the nut on the compression block is loosened by the traditional method, and then the nut is tightened for positioning, the efficiency is very low, and the positioning accuracy is also relatively poor, which is not conducive to large-scale processing and production.

[0014] Through the operation of the cylinder 4 on the positioning block 3, the cylinder 4 is started, and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com