Glass substrate grinding method and grinding device

A glass substrate and grinding method technology, which is applied in grinding devices, grinding machine tools, grinding machines, etc., can solve the problems of weakened adsorption and broken glass substrates, and achieve the effect of preventing pollution and simplifying the liquid supply system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Hereinafter, preferred aspects of the polishing method and polishing apparatus of the glass substrate according to the embodiment of the present invention will be described in detail with reference to the drawings.

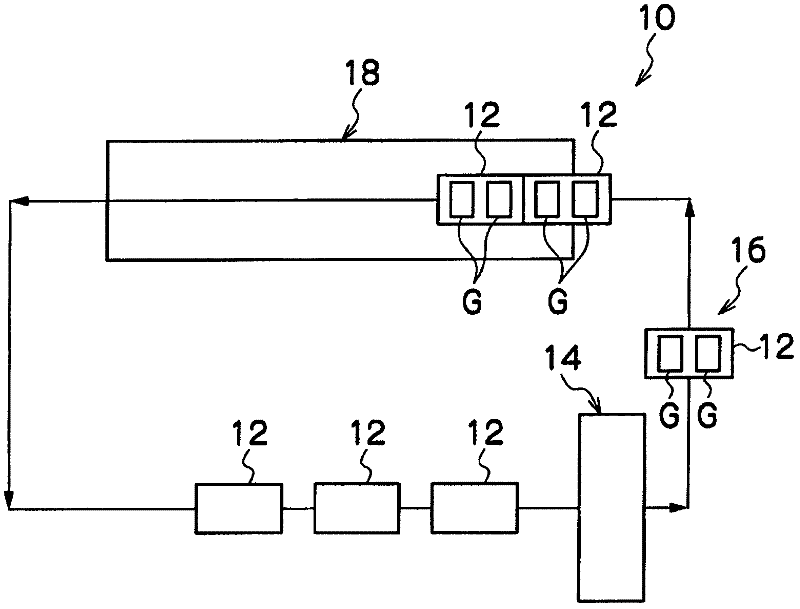

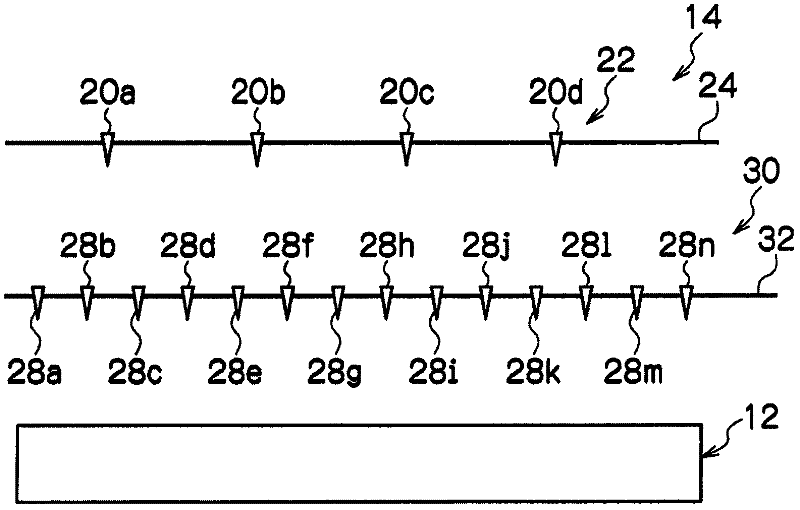

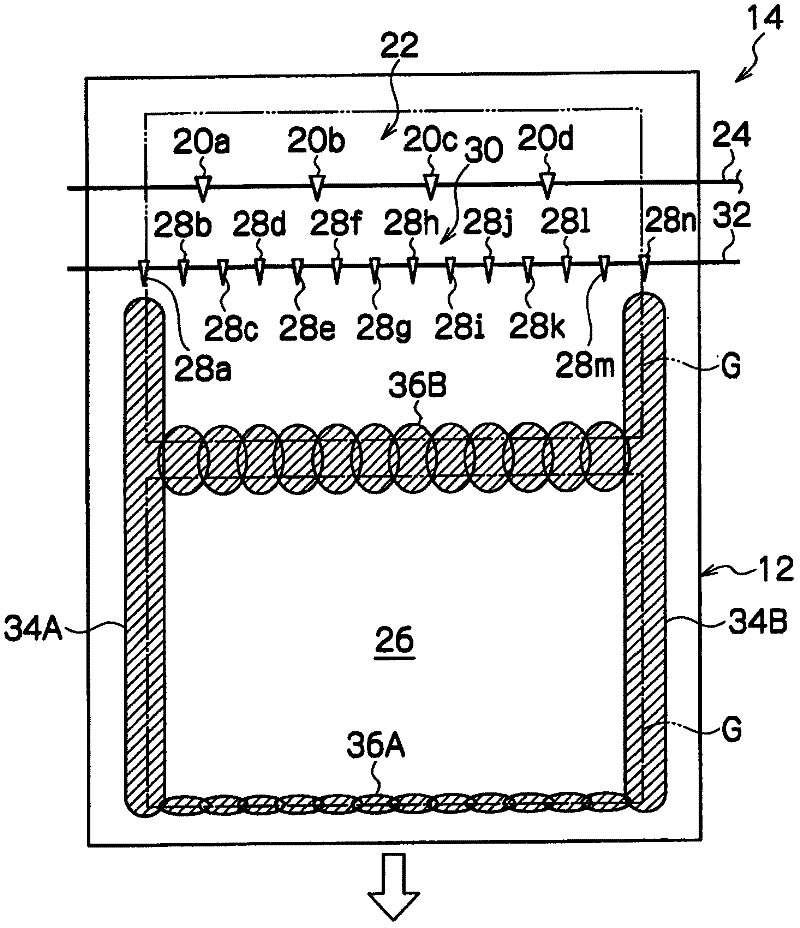

[0079] figure 1 It is a plan view which shows the whole structure of the polishing apparatus 10 of the glass substrate concerning embodiment. exist figure 1 In, the arrow shows the stage conveyance path of the rectangular-shaped stage 12 which adsorb|sucks and fixes the non-polishing surface of the rectangular-shaped glass substrate G.

[0080] On the stage conveyance path, the liquid spray part 14, the glass substrate fixing part 16, and the polishing part 18 are arrange|positioned in this order from the upstream side of a stage conveyance path toward a downstream side. Moreover, the downstream side of the grinding|polishing part 18 is provided with the glass substrate unloading part and the table cleaning part which are not shown in figure.

[0081] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com