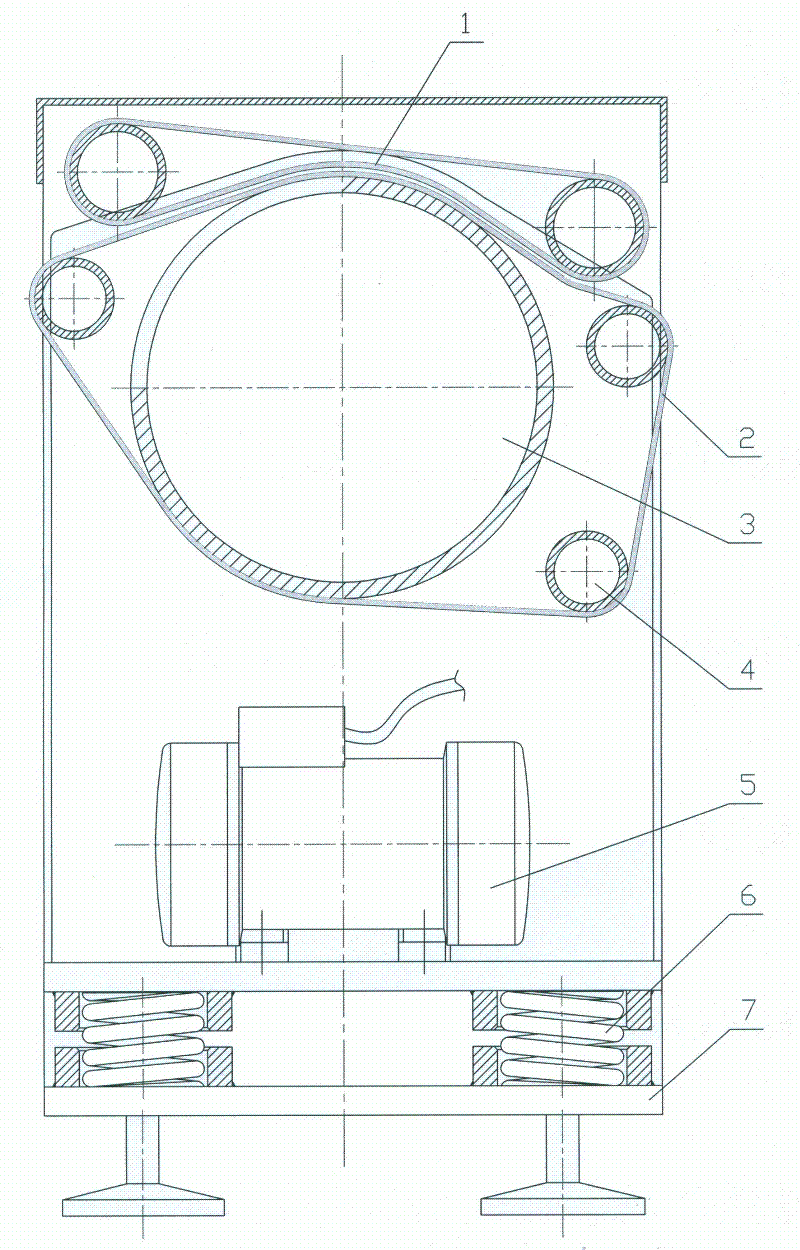

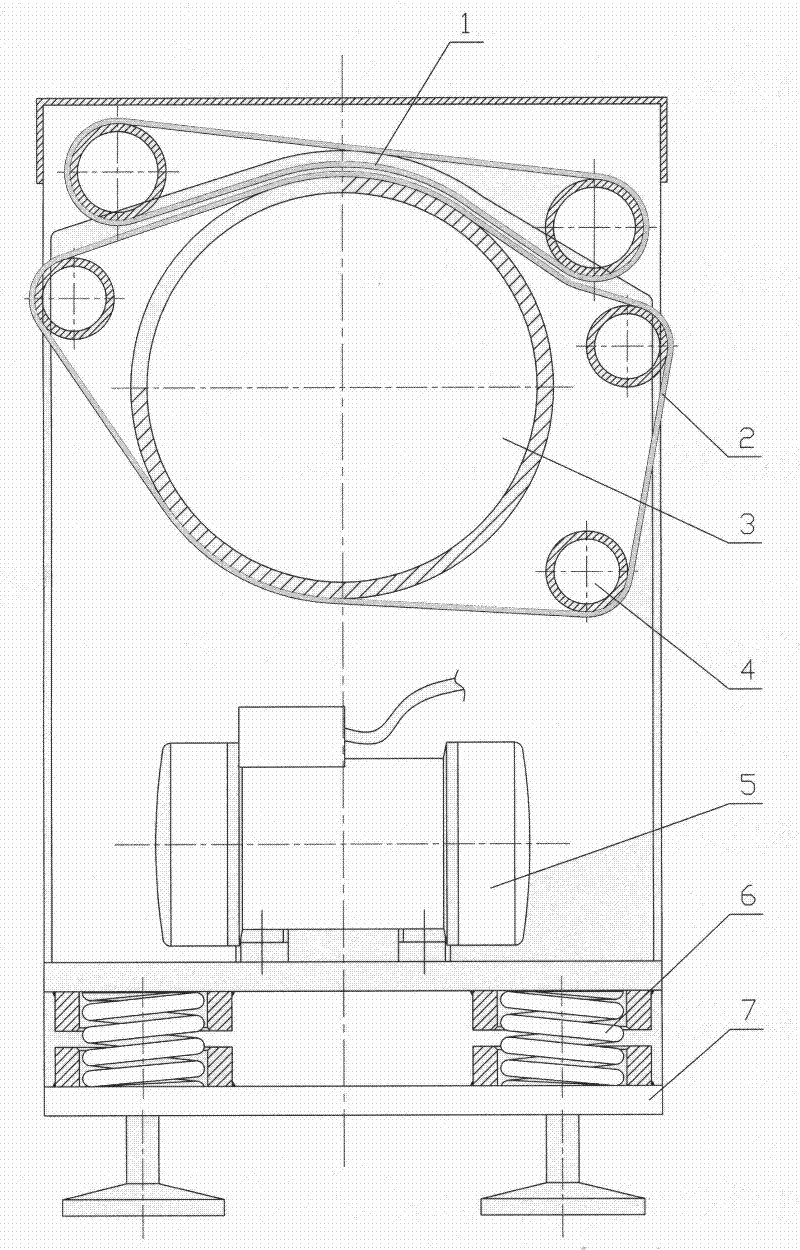

A leveling mechanism of a heating machine

A technology of leveling mechanism and warming machine, applied in packaging and other directions, can solve problems such as difficult balance of force, low work efficiency, uneven distribution, etc., and achieve the effects of prolonging service life, reducing noise, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] With reference to the accompanying drawings, the leveling mechanism of this kind of warm bag machine includes a frame 7 and a transmission device, and the frame 7 is provided with a vibrator 5, and the vibrator 5 includes a vibrating roller 3, and the vibrator 5 A shock-absorbing spring 6 is arranged between the frame 7, and the shock-absorbing spring 6 buffers the vibration generated by the vibrator 5, thereby reducing damage to the frame 7 and the vibrator 5, prolonging its service life, and reducing damage caused by vibration. noise. Described transmission device comprises motor and transmission roller 4, does not draw motor among the figure, and described transmission roller 4 is connected with the output shaft of motor, and described transmission roller 4 and vibrating roller 3 are provided with conveyor belt 2, and described transmission The top of belt 2 is provided with flattening belt 1, and described flattening belt 1 guarantees that the warm paste jumps betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com