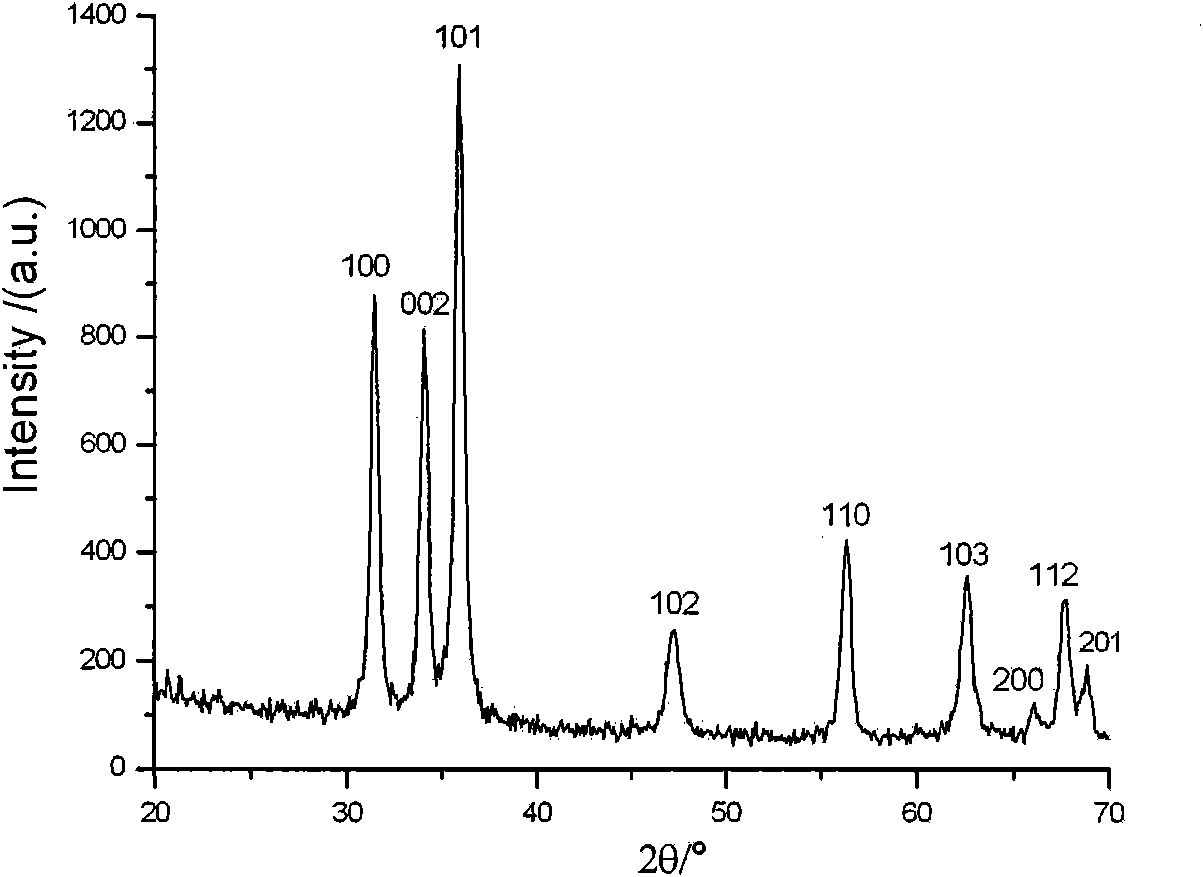

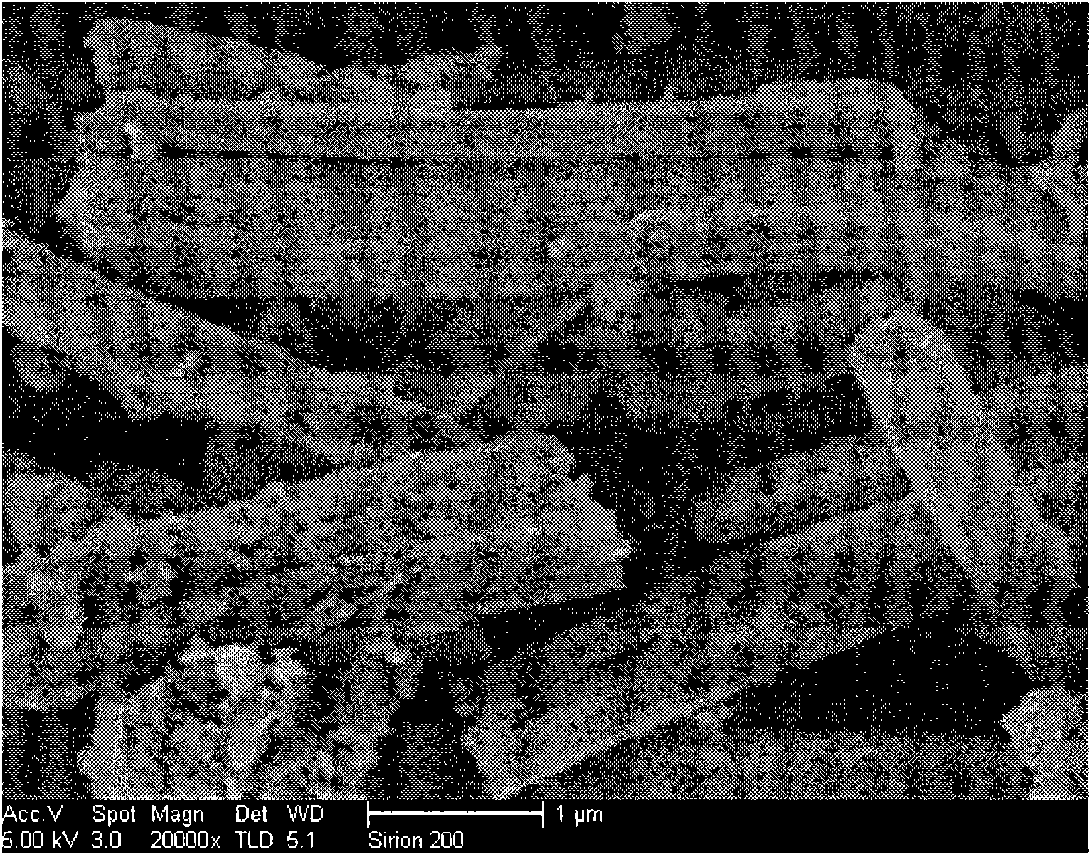

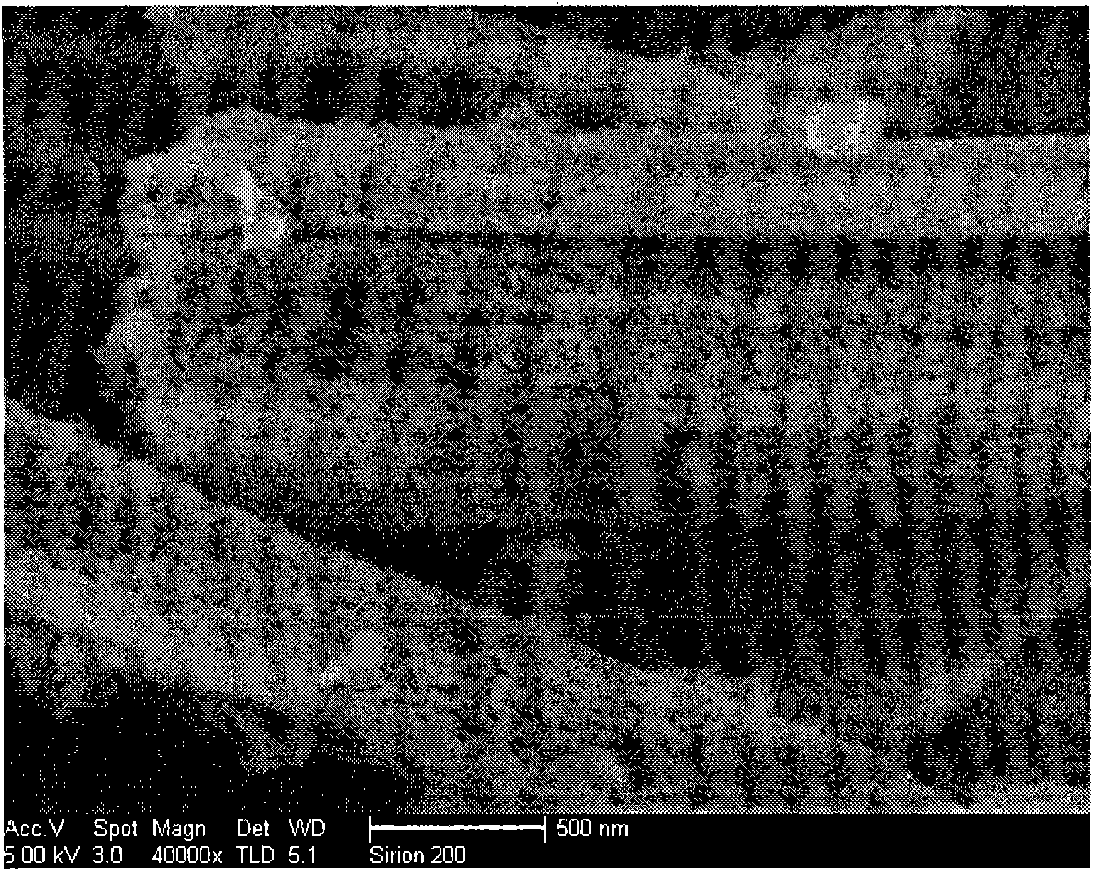

Flesh-colored ZnO porous nanoscale rod-like material and preparation method thereof

A nano-rod-shaped, skin-colored technology, applied in the direction of zinc oxide/zinc hydroxide, etc., to achieve the effect of simple equipment, easy-to-obtain raw materials, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The skin-colored ZnO porous nano-rod material of the present invention is prepared by two-step method of microwave heating and roasting thermal decomposition, that is, zinc oxalate, deionized water and ethylenediamine are used as raw materials, and the reaction solution is dispersed by ultrasonic waves and then heated by microwaves. Precursor compounds are then calcined and thermally decomposed in air. Its specific process steps are as follows:

[0022] 1) Weigh 0.306g of zinc oxalate and disperse it into a suspension with 60mL of deionized water;

[0023] 2) Slowly add 0.14mL ethylenediamine;

[0024] 3) After fully stirring for 30 minutes, sonicate in an ultrasonic cleaner for 10 minutes;

[0025] 4) Cover it with PE film, put it in a household microwave oven, and heat it on low heat for 8 minutes;

[0026] 5) Take out and cool to room temperature naturally, filter the precipitate, wash with deionized water 3 times, put the precipitate in an oven and heat for 8 hou...

Embodiment 2

[0032] The skin-colored ZnO porous nano-rod material of the present invention is prepared by two-step method of microwave heating and roasting thermal decomposition, that is, zinc oxalate, deionized water and ethylenediamine are used as raw materials, and the reaction solution is dispersed by ultrasonic waves and then heated by microwaves. Precursor compounds are then calcined and thermally decomposed in air. Its specific process steps are as follows:

[0033] 1) Weigh 0.306g of zinc oxalate and disperse it into a suspension with 60mL of deionized water;

[0034] 2) Slowly add 0.07mL ethylenediamine;

[0035] 3) After fully stirring for 20 minutes, sonicate in an ultrasonic cleaner for 10 minutes;

[0036] 4) Cover it with PE film, put it in a household microwave oven, and heat it on low heat for 6 minutes;

[0037] 5) Take out and cool to room temperature naturally, filter the precipitate, wash with deionized water 3 times, put the precipitate in an oven and heat for 8 hou...

Embodiment 3

[0041] The skin-colored ZnO porous nano-rod material of the present invention is prepared by two-step method of microwave heating and roasting thermal decomposition, that is, zinc oxalate, deionized water and ethylenediamine are used as raw materials, and the reaction solution is dispersed by ultrasonic waves and then heated by microwaves. Precursor compounds are then calcined and thermally decomposed in air. Its specific process steps are as follows:

[0042] 1) Weigh 0.306g of zinc oxalate and disperse it into a suspension with 60mL of deionized water;

[0043] 2) Slowly add 0.21mL ethylenediamine;

[0044] 3) After fully stirring for 30 minutes, sonicate in an ultrasonic cleaner for 10 minutes;

[0045] 4) Cover it with PE film, put it in a household microwave oven, and heat it on low heat for 10 minutes;

[0046] 5) Take out and cool to room temperature naturally, filter the precipitate, wash with deionized water 3 times, put the precipitate in an oven and heat for 8 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com