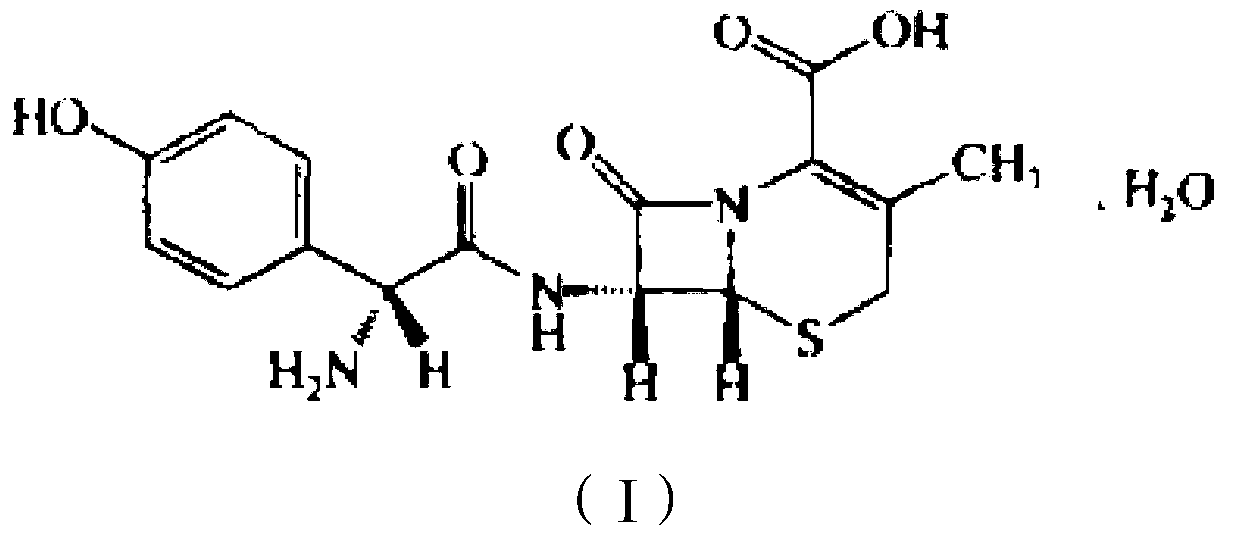

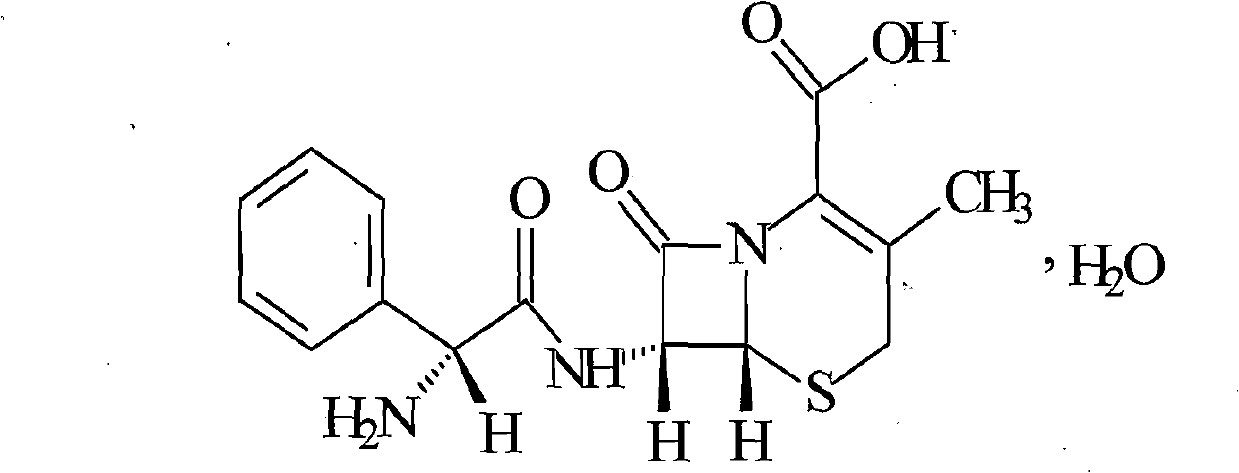

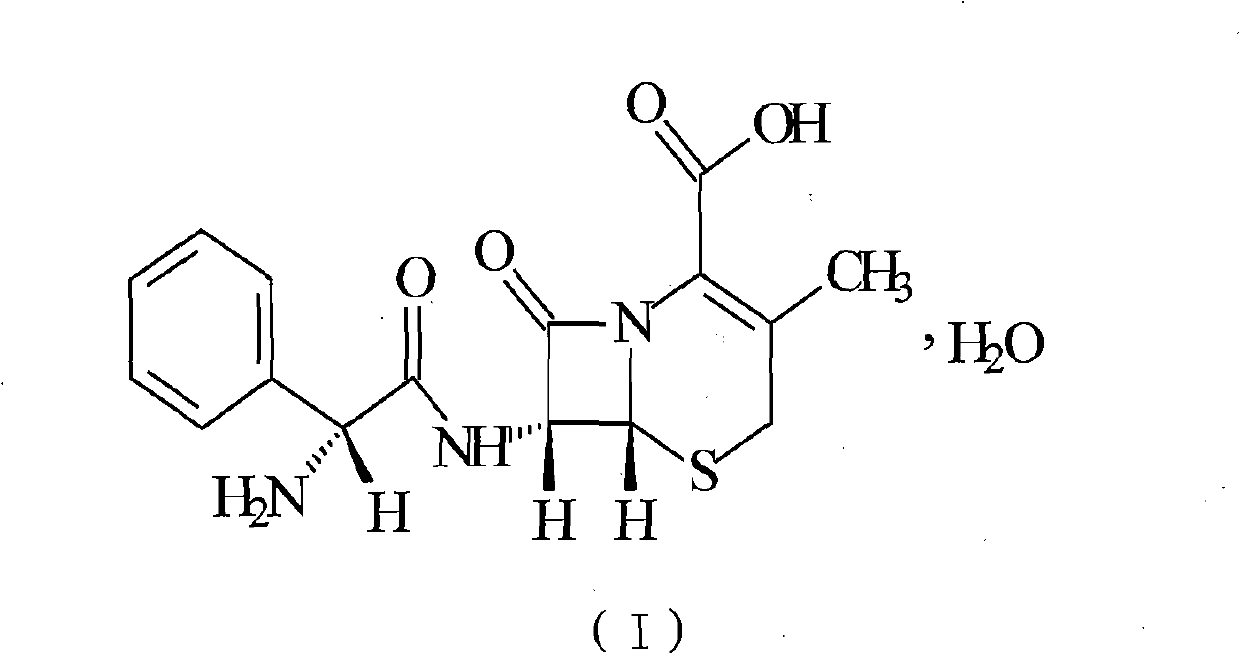

Cefadroxil compound and preparation method thereof

A cefadroxil compound and a technology for cefadroxil are applied in the field of purifying cefadroxil compounds and preparation methods thereof, and can solve the problems of low purity and low yield of cefadroxil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Get 10g cefadroxil crude product, the content of cefadroxil recorded by high performance liquid chromatography is 94%, and the polymer content measured by gel chromatography system is 3%. Add ethanol to the raw material cefadroxil, control the temperature not to exceed 28°C, stir vigorously, and then filter, wash the filter cake with ethanol at a temperature of 12-14°C, and air dry.

[0050] The filter cake is put into 18% ammonia water, and the treatment time is 2 hours, until the aqueous solution reaches weak alkalinity, preferably with a pH value not exceeding 8.5. Stirring is carried out during the treatment, and the separated precipitate is filtered off. Then the aqueous solution was heated to 40°C to remove the remaining ammonia gas components in the aqueous solution.

[0051] Slowly add hydrochloric acid with a concentration of 2 mol / L to the obtained ammonia solution of cefadroxil, control the temperature at 40° C., and finally control the pH at 5.0, keep it fo...

Embodiment 2

[0054] Get 10g cefadroxil crude drug (Suzhou Zhonglian Chemical Pharmaceutical Co., Ltd., batch number: 20100906), the purity of cefadroxil recorded by high performance liquid chromatography is 96%, and the polymer impurity content measured by gel chromatography is 2.2%. Add diethyl ether to the raw material cefadroxil, control the temperature not to exceed 25°C, stir vigorously, then filter, wash the filter cake with diethyl ether at a temperature of 10-13°C, and dry in vacuum.

[0055] The filter cake is put into 15% ammonia water, and the treatment time is 3 hours, until the aqueous solution reaches weak alkalinity, preferably the pH value is not more than 9. Stirring is carried out during the treatment, and the separated precipitate is filtered off. Then the aqueous solution was heated to 45°C to remove the remaining ammonia gas components in the aqueous solution.

[0056] Slowly add hydrochloric acid with a concentration of 1.8 mol / L to the ammonia solution of cefadroxil...

Embodiment 3

[0059] Get the longer cefadroxil bulk drug (Shanxi Weiqida Pharmaceutical Co., Ltd., batch number: 20080215) of 10g production date, the purity of cefadroxil recorded by high performance liquid chromatography is 92%, and the gel chromatography is determined polymer Impurity content 5%. Adding ethanol to the raw material cefadroxil, controlling the temperature not to exceed 20°C, vigorously stirring, and then filtering, washing the filter cake with ethanol at a temperature not exceeding 12-15°C, and vacuum drying.

[0060] Put the filter cake into ammonia water with a concentration of 20%, and the treatment time is 4 hours, until the aqueous solution reaches weak alkalinity, preferably the pH value is not more than 8. Stirring is carried out during the treatment, and the separated precipitate is filtered off. Then the aqueous solution was heated to 50°C to remove the remaining ammonia gas components in the aqueous solution.

[0061] Slowly add hydrochloric acid with a concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com