A two-color elastic clothing fabric with strong three-dimensional effect

A three-dimensional, fabric technology, applied in the field of clothing fabrics, can solve the problems of inability to be refined, unable to overcome the flat feeling, and use too many threads, and achieve the effect of filling the gap, obvious three-dimensional effect and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

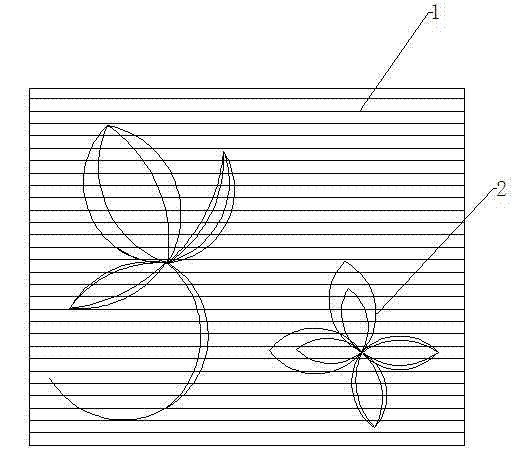

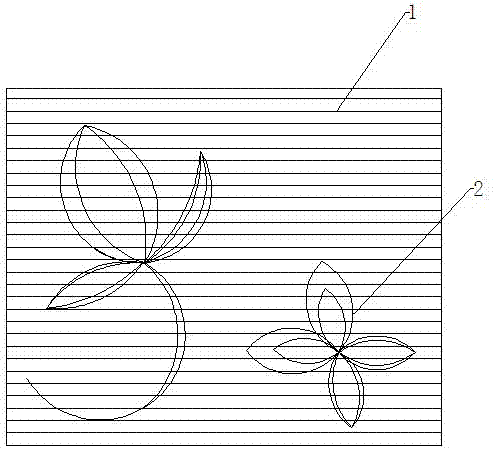

[0012] What the present embodiment makes is to be the base color of gray purple with pinstripes, and pattern line is the cloth blank of purple. Such as figure 1 Shown: Cloth 1 is gray-purple with thin stripes, and the border of pattern 2 is purple.

[0013] In this example, 40s cotton purple yarns and 40s light gray yarns are used as the wefts, and the arrangement of the purple and light gray yarns is 1 light gray yarn between every 20 purple yarns; light gray 40s yarns are used Lines are warps. When weaving, the composition of the lines is that the ground part adopts plain weave, and the flower part adopts weft satin weave plus 4:1 spandex.

[0014] The jacquard part of the woven fabric is conventionally wrinkled and finished to obtain a three-dimensional patterned fabric with good visual effect and natural pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com