New one-piece wheel train

A one-piece, wheel train technology, which is applied to portable lifting devices, belts/chains/gears, components with teeth, etc., can solve the problems that the belt and the wheel train cannot cooperate well and affect the belt transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

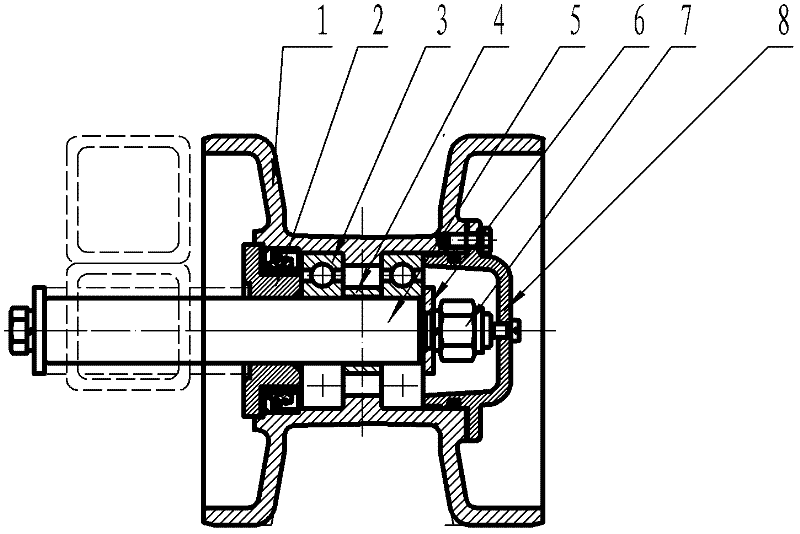

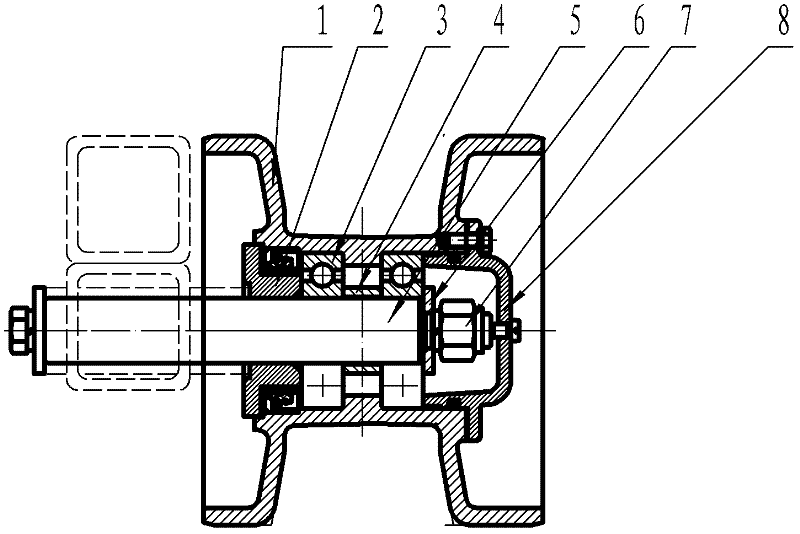

[0009] Such as figure 1 As shown, the conjoined track roller 1 of the present invention is interference-fitted with the outer circles of the two bearings 3 through the bearing holes, and the two bearings 3 are spaced apart by a spacer 4, and the outer circle of the oil seal 2 is in contact with the outer circle of the two bearings 3 . The outer circle of the mandrel 5 and the inner hole of the bearing 3 have an interference fit, and are positioned by the end face of the bearing 3. After the mandrel 5 is fitted with the inner hole of the washer 6, it is locked and fixed by the nut 7, and the end cover 8. After the outer circle cooperates with the inner hole of the one-piece supporting wheel 1, it is locked and fixed with bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com