An explosion-proof fire-stop breathing valve

A breathing valve and fire-blocking technology, which is applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problems of airtightness and flexibility that cannot be balanced, and affect the performance of breathing valves, so as to solve the problem of airtightness and flexibility that cannot be balanced , Increase the effect of lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

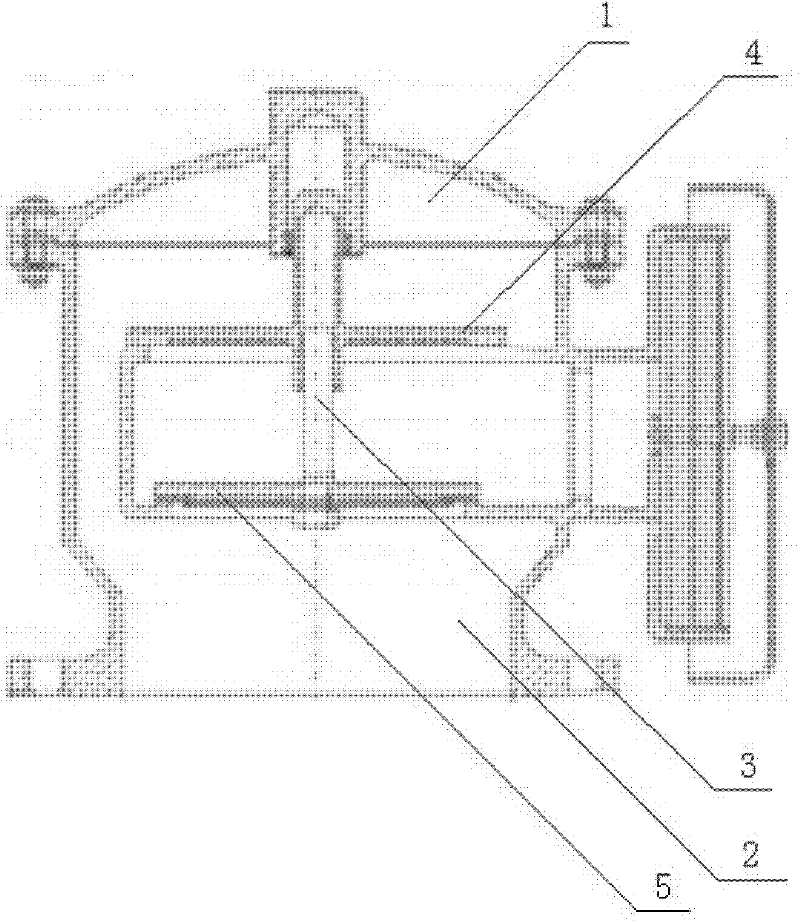

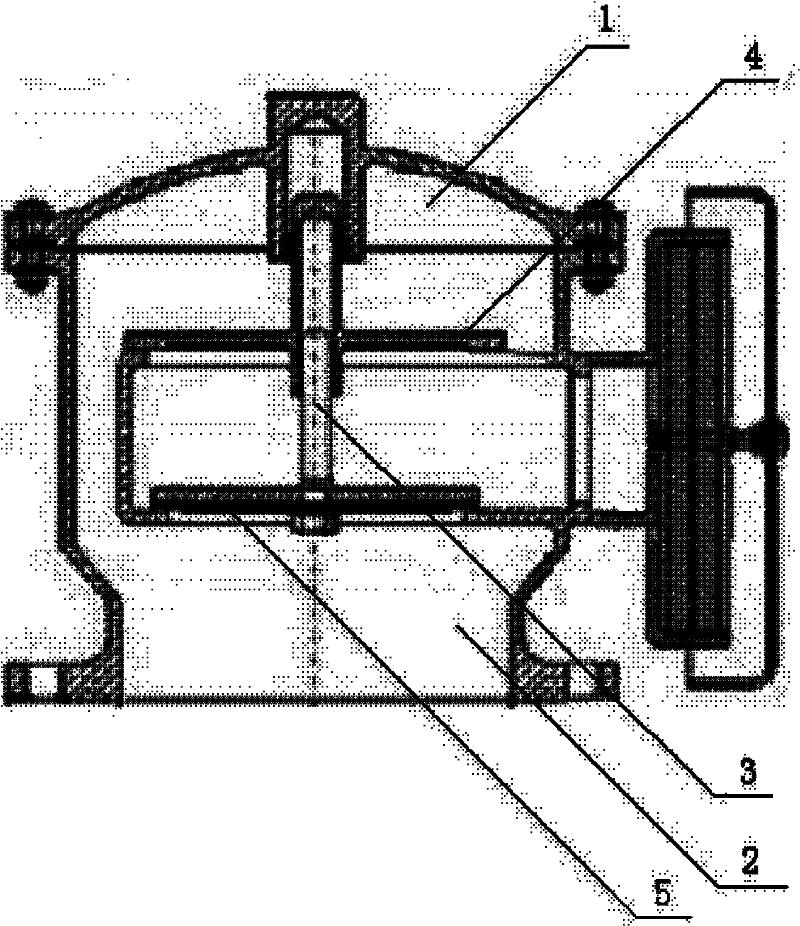

[0013] For further illustrating the present invention, now cooperate with accompanying drawing to elaborate:

[0014] An explosion-proof and fire-resistant breathing valve, which consists of a valve cover 1, a valve body 2 and an air flow channel 3, the valve cover 1 and the valve body 2 are fixedly connected by bolts, the air flow channel 3 is placed at the inner central axis of the valve body 2, and also includes Positive pressure valve disc 4 and negative pressure valve disc 5, the positive pressure valve disc 4 is vertically fixed on the upper end of the air flow channel 3 through the valve disc motion control device, and the negative pressure valve disc 5 is vertically fixed on the air flow channel 3 through the valve disc motion control device At the lower end, the positive pressure valve disc 4 and the negative pressure valve disc 5 are circular airbags, and nitrogen is filled between the positive pressure valve disc 4 and the negative pressure valve disc 5, and the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com