A cast iron plate type air preheater

A technology of air preheater and cast iron plate, which is applied in the direction of heat exchanger, heat exchanger type, indirect heat exchanger, etc., can solve the problem that the air preheater cannot be compared, and achieve the effect of low leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

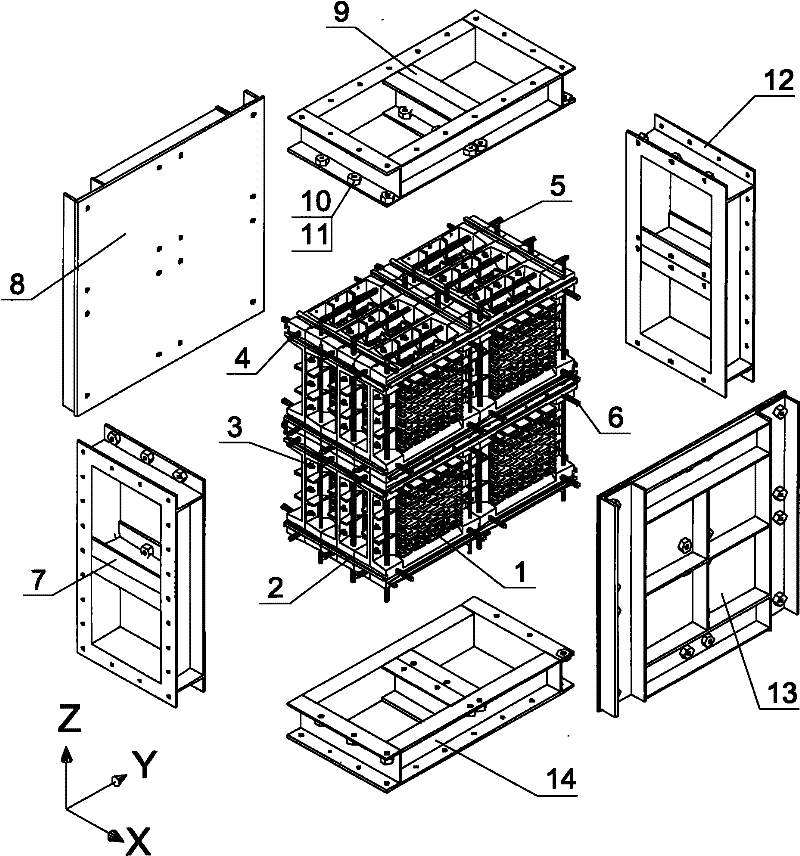

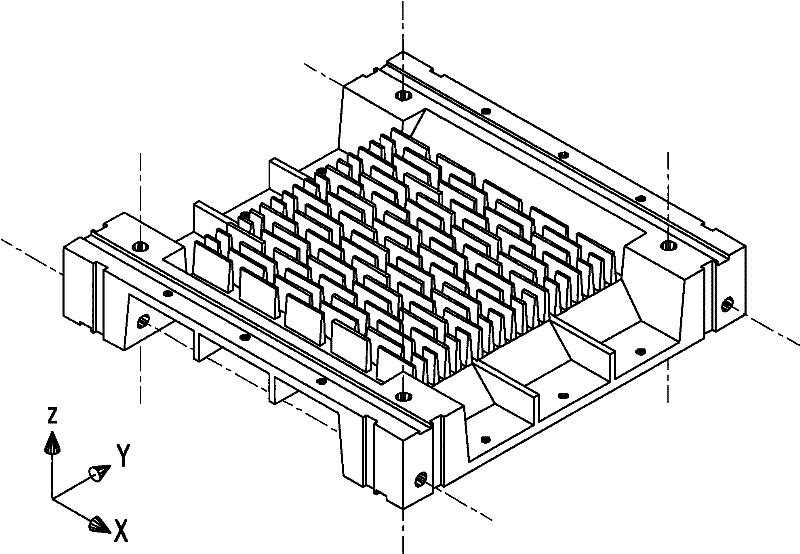

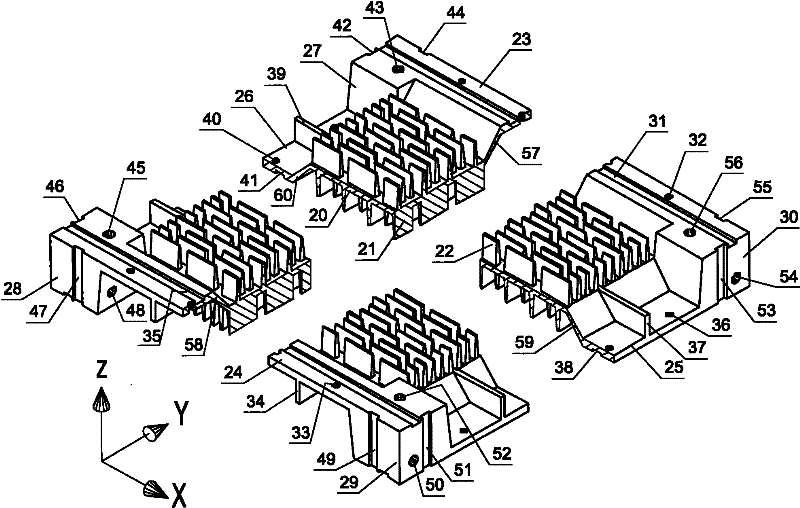

[0045] figure 1 It is a three-dimensional assembly diagram of a cast iron plate air preheater of the present invention. The multiple cast iron heat transfer plates 1 are connected in a three-dimensional space, the contact surfaces of the adjacent cast iron heat transfer plates are sealed with a sealing material 2, and the four sides of the adjacent cast iron heat transfer plates 1 are sealed by connecting bolts and nuts 3. The cast iron heat transfer plates 1 in the three-dimensional space are connected in three-dimensional series through the X-direction rod 6, the Y-direction rod 4 and the Z-direction rod 5. At the same time, through the X-direction rod 6, Y-direction rod 4, Z-direction rod 5, rod nut 10 and spring washer 11, the cast iron heat transfer plate 1 in the three-dimensional space, the air inlet frame 7, the left side sealing frame 8, the smoke The air inlet frame 9, the air outlet frame 12, the right side sealing frame 13, and the flue gas outlet frame 14 are tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com