A complete set of equipment and method for rapid hydrogen charging based on gas drive pressurization technology

A gas-driven and fast technology, which is applied to the device that can be quietly and quickly pressurized. The compression efficiency is not high and cannot be used, so as to achieve the effect of high compression efficiency, good function, and elimination of potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

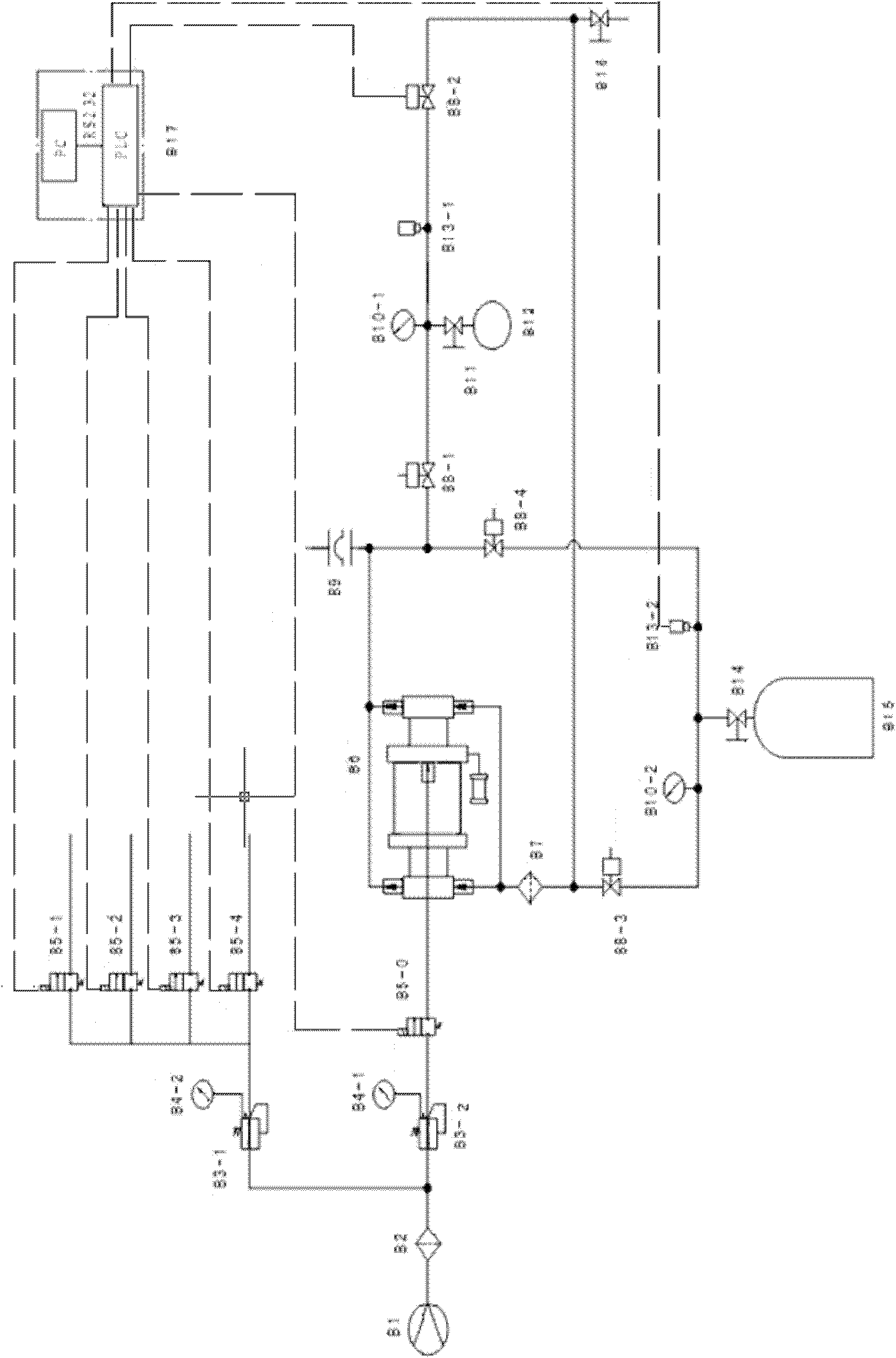

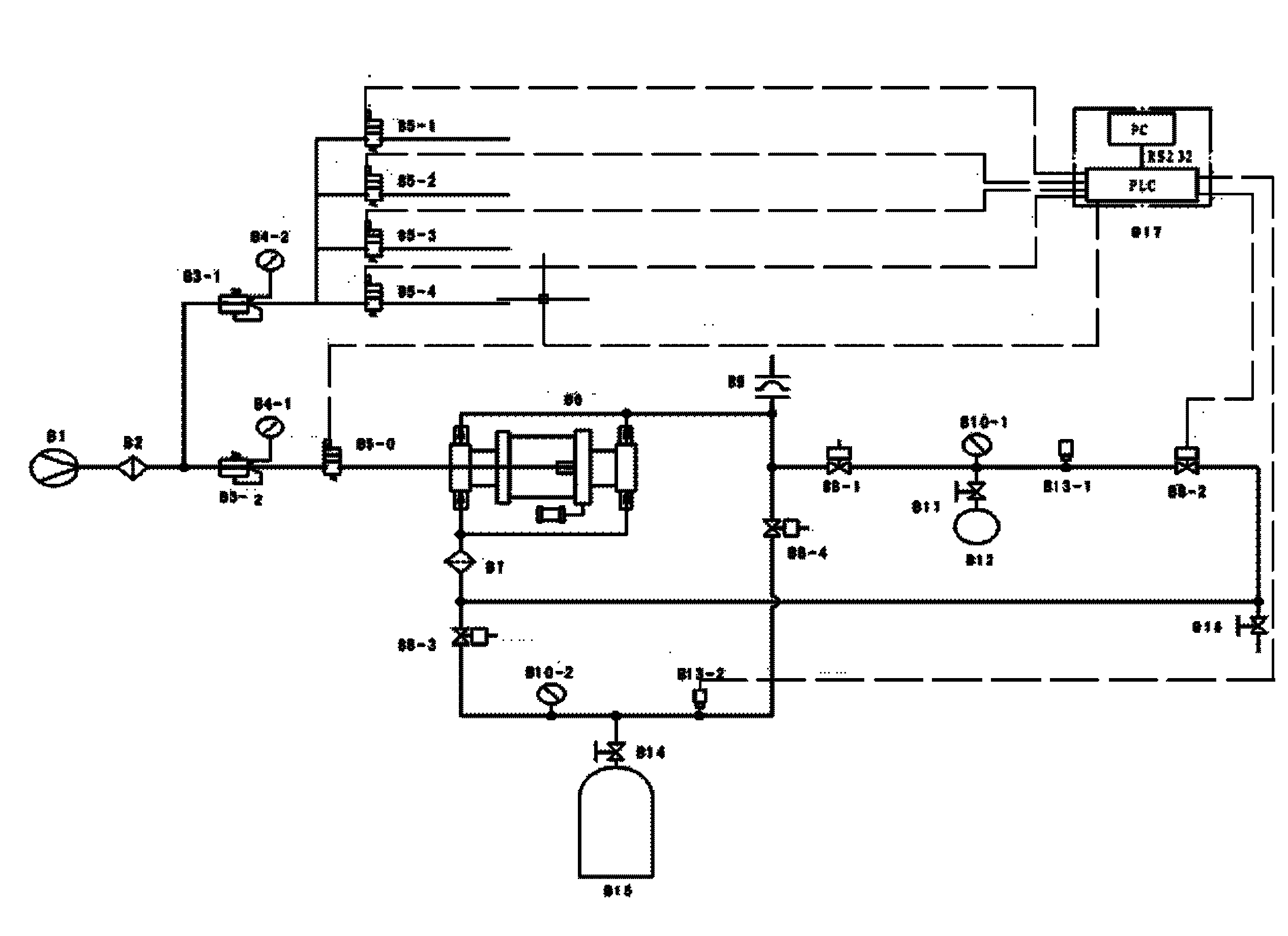

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] like figure 1 As shown, a complete set of rapid hydrogen charging equipment based on gas-driven booster technology, which includes pre-increased hydrogen storage tank B15, gas-driven booster pump B6, tested hydrogen storage tank B12, first pressure sensor B13-1, PLC The controller B17, the first to fourth solenoid valves B5-1-B5-4, the first to fourth air control valves B8-1-B8-4 and the fifth solenoid valve B5-0 controlled by the corresponding solenoid valves, the The air inlet of the air-driven booster pump B6 is connected to the corresponding outlet pipelines of the tested hydrogen storage tank B12 and the pre-increased hydrogen storage tank B15, and the gas outlet of the air-driven booster pump B6 is connected to the tested hydrogen storage tank B12 and the pre-increased hydrogen storage tank B15. The corresponding intake pipeline of the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com