A Fatigue Design Method for Deepwater Riser

A design method and riser technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of deep water riser fatigue damage, fatigue damage, service period extension, etc., to achieve simple linear superposition science, Effects in line with the laws of nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with specific embodiments.

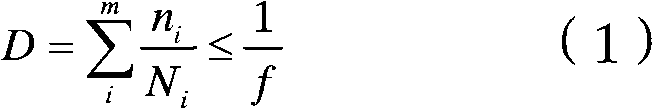

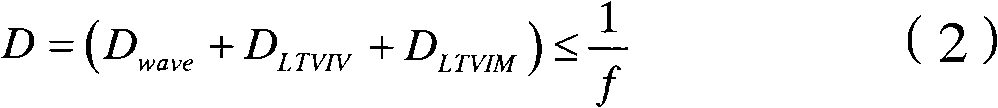

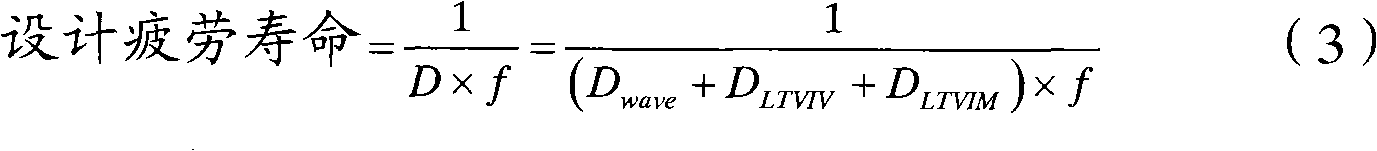

[0040] Short-term flow is an "occasional" strong flow field, but because it is not an environmental phenomenon that occurs every year, the existing deep-water riser fatigue design method does not consider short-term flow vortex-induced vibration when calculating the design fatigue life of the riser Induced fatigue damage, that is, short-term flow-induced fatigue damage is not included in the calculation of cumulative fatigue damage. However, due to the high strength of the short-term flow (large flow velocity), the fatigue damage caused by the short-term flow is calculated separately in the existing deep-water riser fatigue design. This is obviously unreasonable, because the fatigue damage caused by the short-term flow will not "heal" with the disappearance of the short-term flow, it will still exist in the riser and accumulate with the original fatigue damage and subsequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com