Fairing system for a horizontal stabilizer of an aircraft and method for installing the same

A system installation, fairing technology, applied in the field of fairing systems, can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

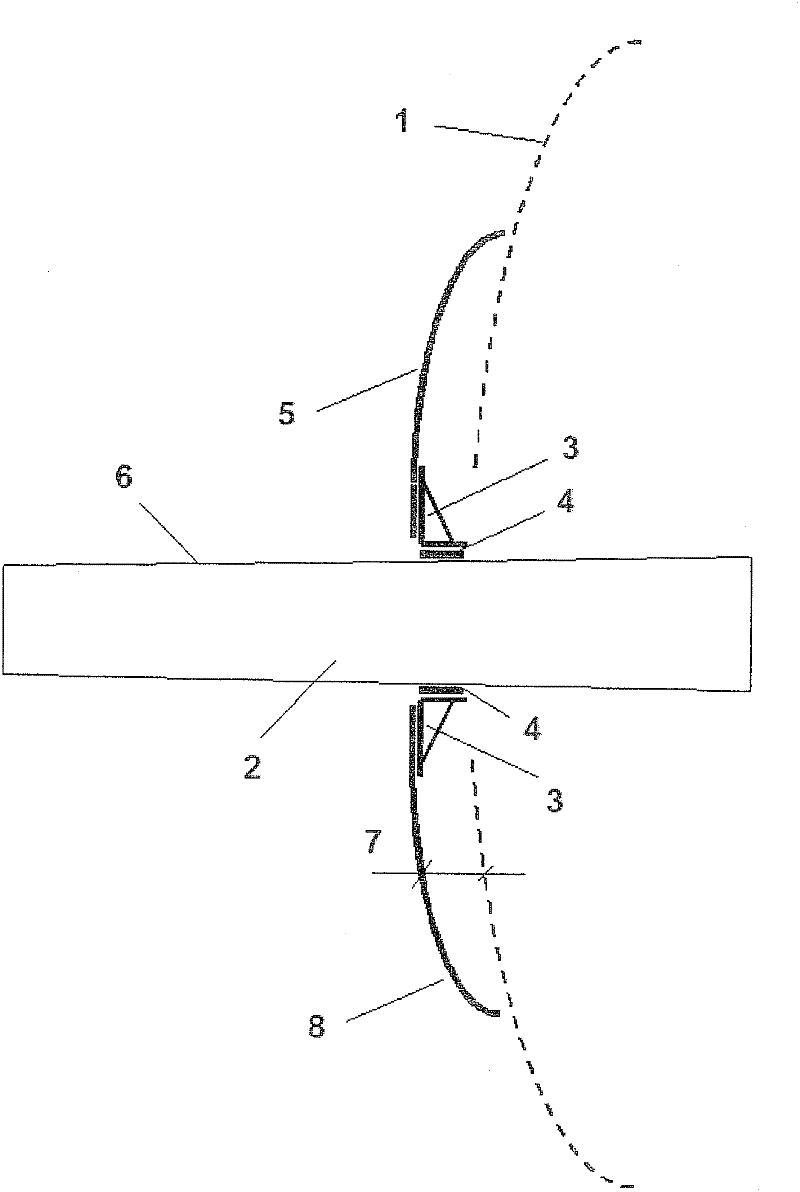

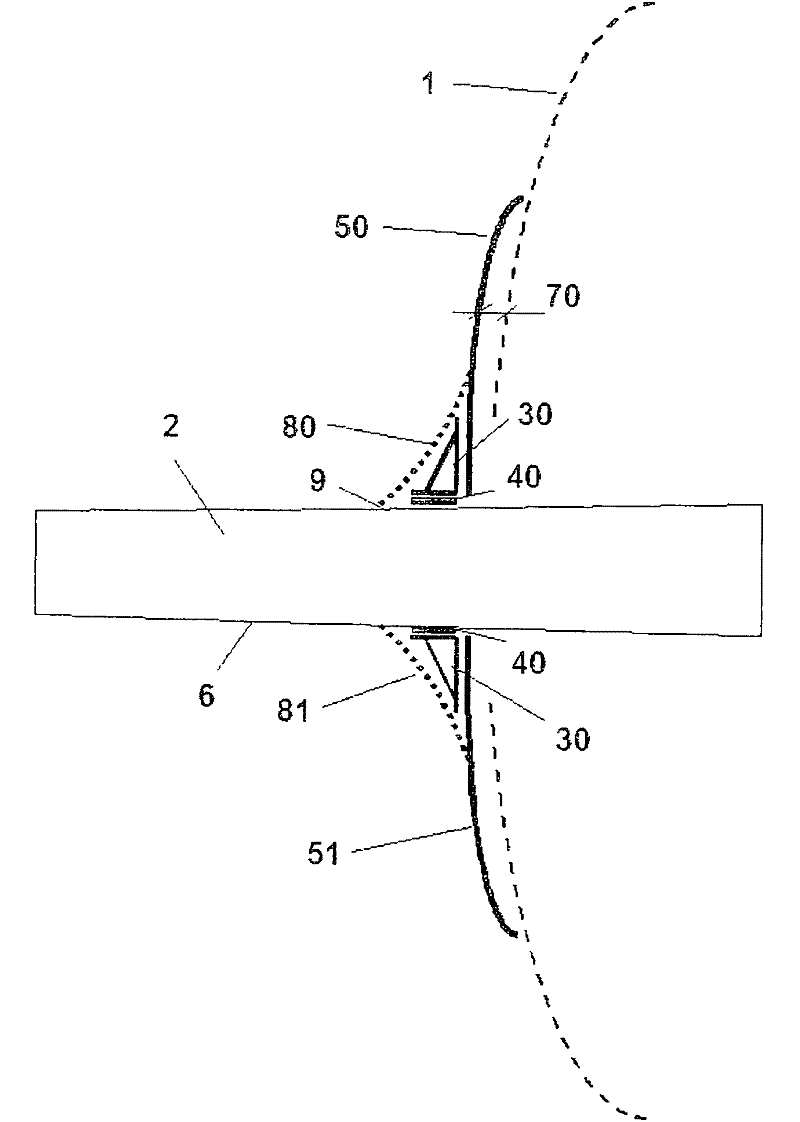

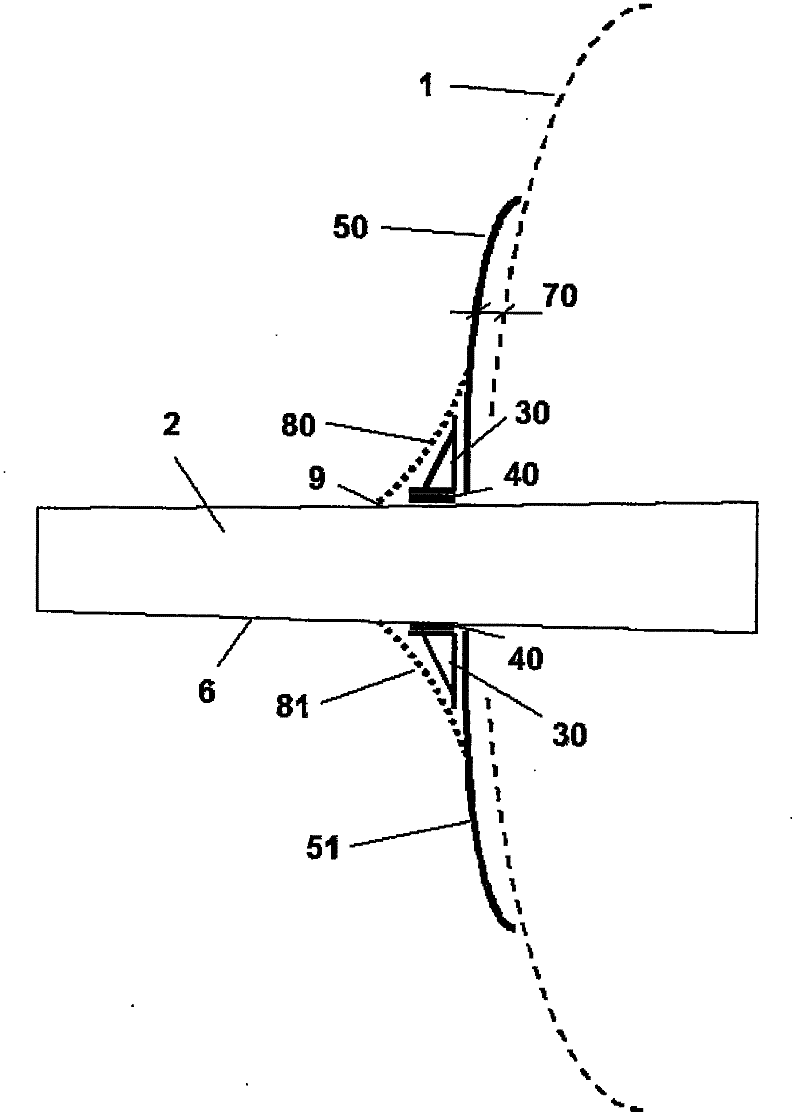

[0013] According to known technology ( figure 1 ), the supporting system for supporting the upper fairing 5 and the lower fairing 8, which cover the fuselage 1 of the aircraft and its adjustable level, are executed from the inside of the aforementioned upper fairing 5 and lower fairing 8 The gap that exists between the stabilizers 2. Said upper fairing 5 and lower fairing 8 are connected to the skin 6 of the horizontal stabilizer 2 by means of supports 3 and bases 4 . The actual upper fairing 5 and lower fairing 8 thus hide these supports 3 on the exterior of the fuselage.

[0014] Thanks to a structure similar to that described above, the support 3 of the fairings 5 and 8 is free to move until it is secured to the base 4 of said support, which is connected to the skin 6 of the horizontal stabilizer 2, so that once it has Once its correct position is achieved the movement of the support is restricted. In the conventional fairings 5 and 8, this setting or adjustment is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com