A three-roll spiral groove rolling mill

A technology of helical hole and rolling mill, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of single production variety, difficult to adapt to the processing of multi-variety parts, complex overall design, etc. The effect of advanced angle, reasonable overall design and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

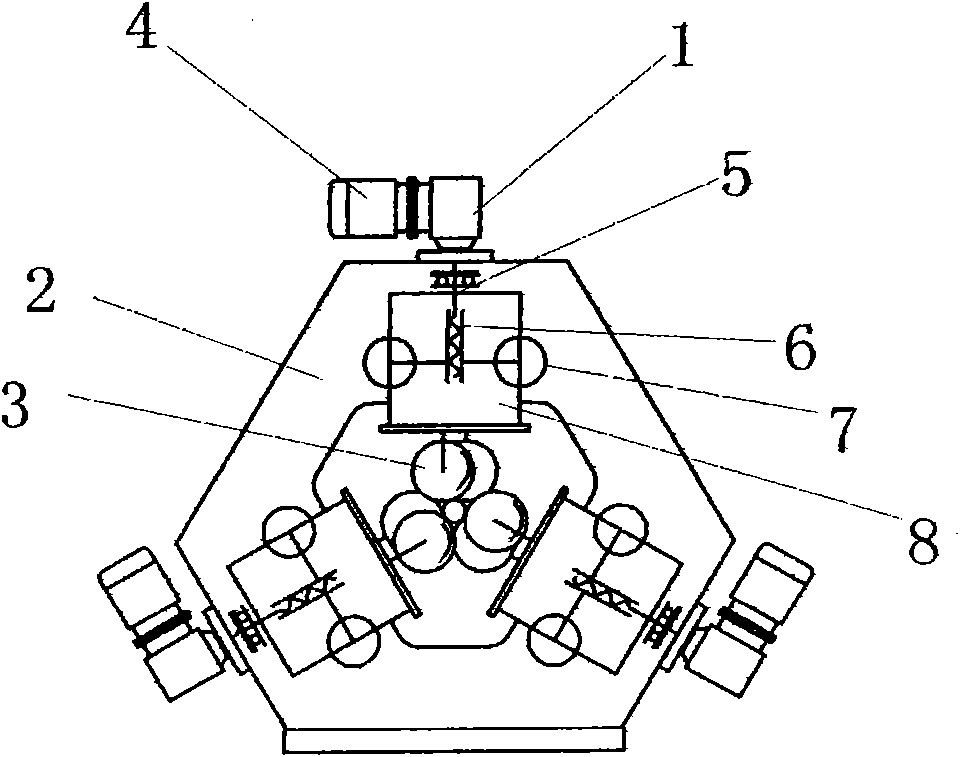

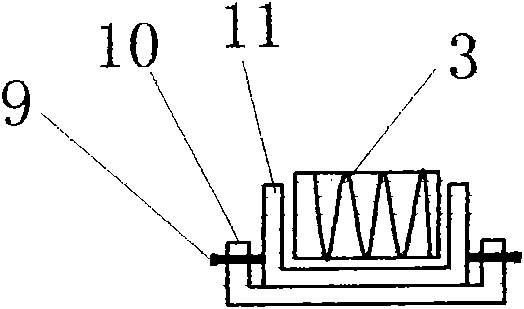

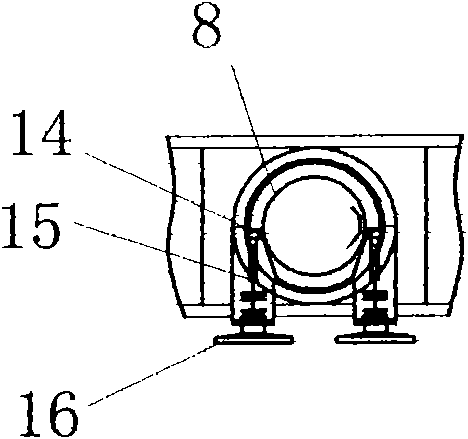

[0012] The present invention as figure 1 , figure 2 , image 3 , Figure 4 As shown, a three-roller spiral groove rolling mill includes a roll device 1 and a frame 2, and the roll device 1 includes three sets of roll assemblies installed on the frame 2 in the shape of a product, and each roll assembly consists of The roll 3, the roll reduction adjustment mechanism, the roll axial adjustment mechanism and the roll feed angle adjustment mechanism, wherein: the above-mentioned roll reduction adjustment mechanism includes a motor 4, a screw shaft 5 depression nut 6 and a rotating drum 8. One end of the screw shaft 5 is driven and connected with the motor 4, and the other end drives the drum to move up and down by pressing down the nut 6; the above-mentioned roll axial adjustment device includes a roll tray 10, a roll stand 11 and a roll 3, and the roll stand 11 is slidingly arranged on the roll tray 10, and adjusting bolts 9 are respectively arranged on both sides of the roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com