U-rib welding process of steel bridge deck

A steel bridge deck and welding process technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of reduced welding efficiency and inability to achieve simultaneous welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

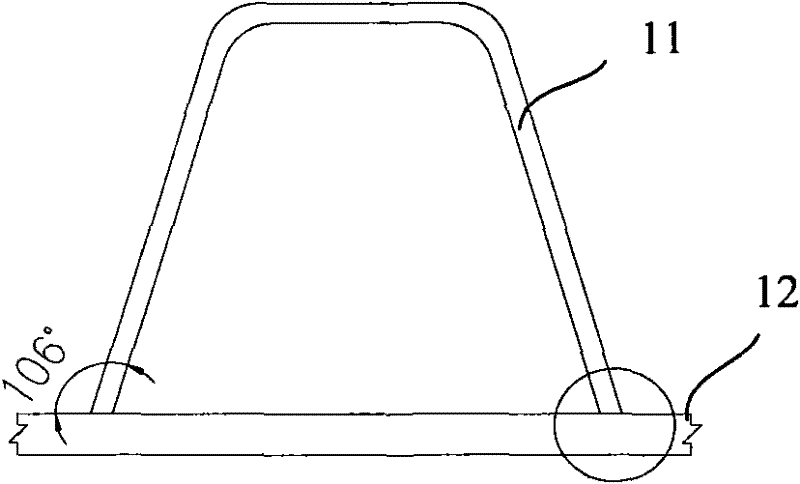

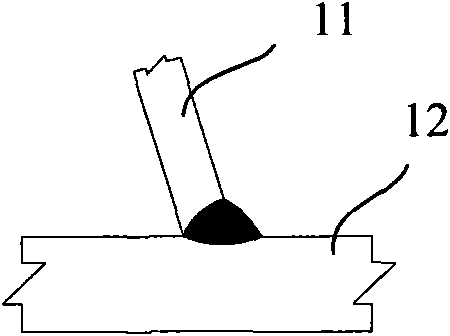

[0021] Figure 1A A schematic diagram showing the welding of steel bridge deck and U-rib. As shown in FIG. 1 , the two ends of the U rib 11 are placed at the welding position of the steel bridge deck 12 to wait for welding. The thickness of the U-rib used in this embodiment may be 12 mm or more, the thickness of the bottom plate may be 14-30 mm, and the angle between the U-rib and the bottom plate may be 106°. Typically, the welding requirement is that the weld penetration should exceed 80%. In addition, the workpiece material is ASTM A709M345.

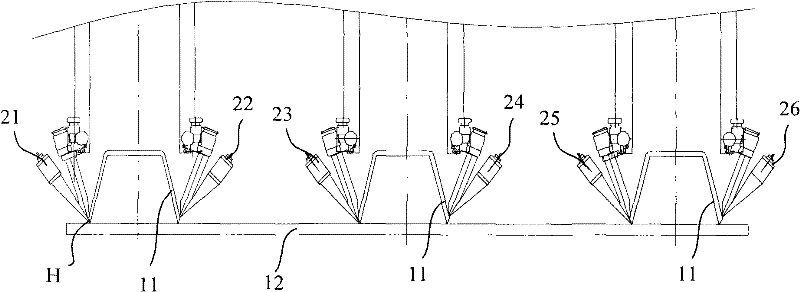

[0022] In the embodiment of the present invention, according to the requirements of AWS D1.5, the welding procedure qualification test and the mechanical property test of the selected welding material are carried out to determine the required mechanical properties of the welding material, thereby determining the appropriate welding process. In summary, the welding process adopts the method of solid core wire mixed gas bottoming and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com