Yarn dyeing method with controllable ring dyeing effect and indigo-dyed yarn

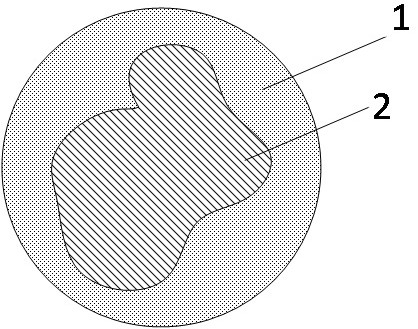

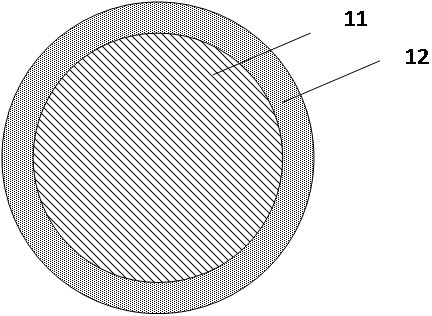

A yarn dyeing and ring dyeing technology is applied in the field of dyeing and finishing of denim fabrics, which can solve the problems of uncontrollable effect of ring dyeing of cotton yarns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] (1) Cotton yarn is subjected to scouring treatment: scouring enzyme 3g / L, penetrant 2g / L, treatment time 5min, treatment temperature 95°C.

[0086] (2) Soften the cotton yarn: steam the yarn with a pressure of 4 atmospheres, and release the pressure after 4 minutes of treatment.

[0087] (3) Waterproof treatment of cotton yarn: Put the cotton yarn into the waterproof treatment solution, pass the padding process, and go through two padding treatments, one dipping and one rolling; the cotton yarn after the padding treatment is baked, and the baking temperature is 150°C, treatment time 3min.

[0088] Wherein, the waterproof treatment liquid includes 40g / L of DM-6118N waterproofing agent of Demei Fine Chemicals, 5g / L of DM-3918 bridging agent of Demei Fine Chemicals, and 2g / L of crosslinking agent with trade name CATAL MK NEW. L.

[0089] (4) Carry out baking treatment on cotton yarn: the baking temperature is 150°C, and the treatment time is 2 minutes.

[0090] (5) Poly...

Embodiment 2

[0103] (1) Cotton yarn is subjected to scouring treatment: scouring enzyme 4g / L, penetrant 3g / L, treatment time 4min, treatment temperature 90°C.

[0104] (2) Soften the cotton yarn: steam the yarn with a pressure of 3 atmospheres, and release the pressure after 3 minutes of treatment.

[0105] (3) Waterproof treatment of cotton yarn: Put the cotton yarn into the waterproof treatment solution, pass the padding process, and go through two padding treatments, one dipping and one rolling; the cotton yarn after the padding treatment is baked, and the baking temperature is 170°C, treatment time 2min.

[0106] Wherein, the waterproof treatment liquid includes 50g / L of DM-6118N waterproofing agent of Demei Fine Chemicals, 10g / L of DM-3918 bridging agent of Demei Fine Chemicals, 4g / L of crosslinking agent with trade name CATAL MK NEW L.

[0107] (4) Baking treatment of cotton yarn: the baking temperature is 180°C, and the treatment time is 1min.

[0108] (5) Polyurethane (PU) paddi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com