A gas permeability testing device

A gas permeability and testing device technology, which is applied in the direction of measuring devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as gas permeability testing, achieve simple structure, high flexibility, and reduce errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

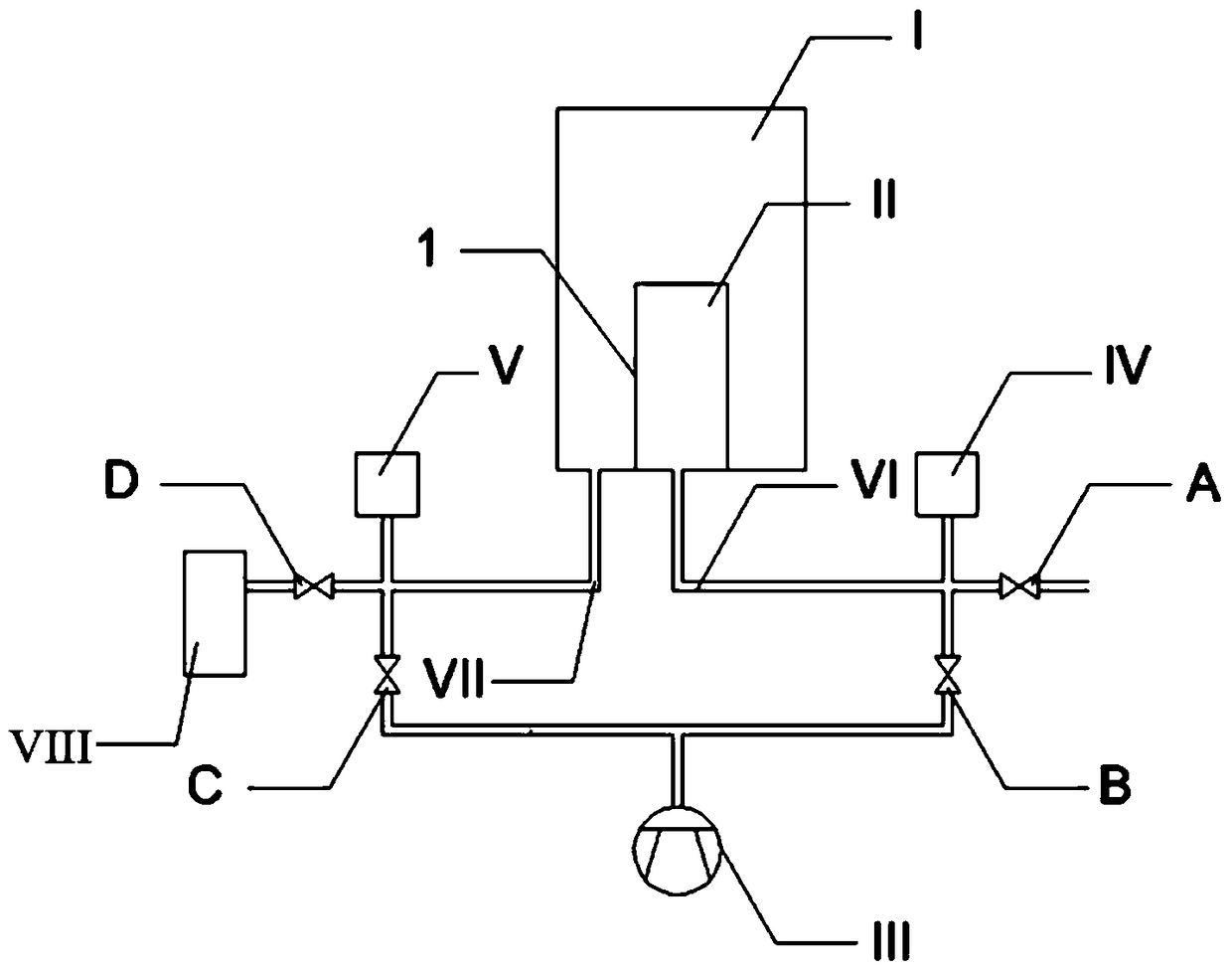

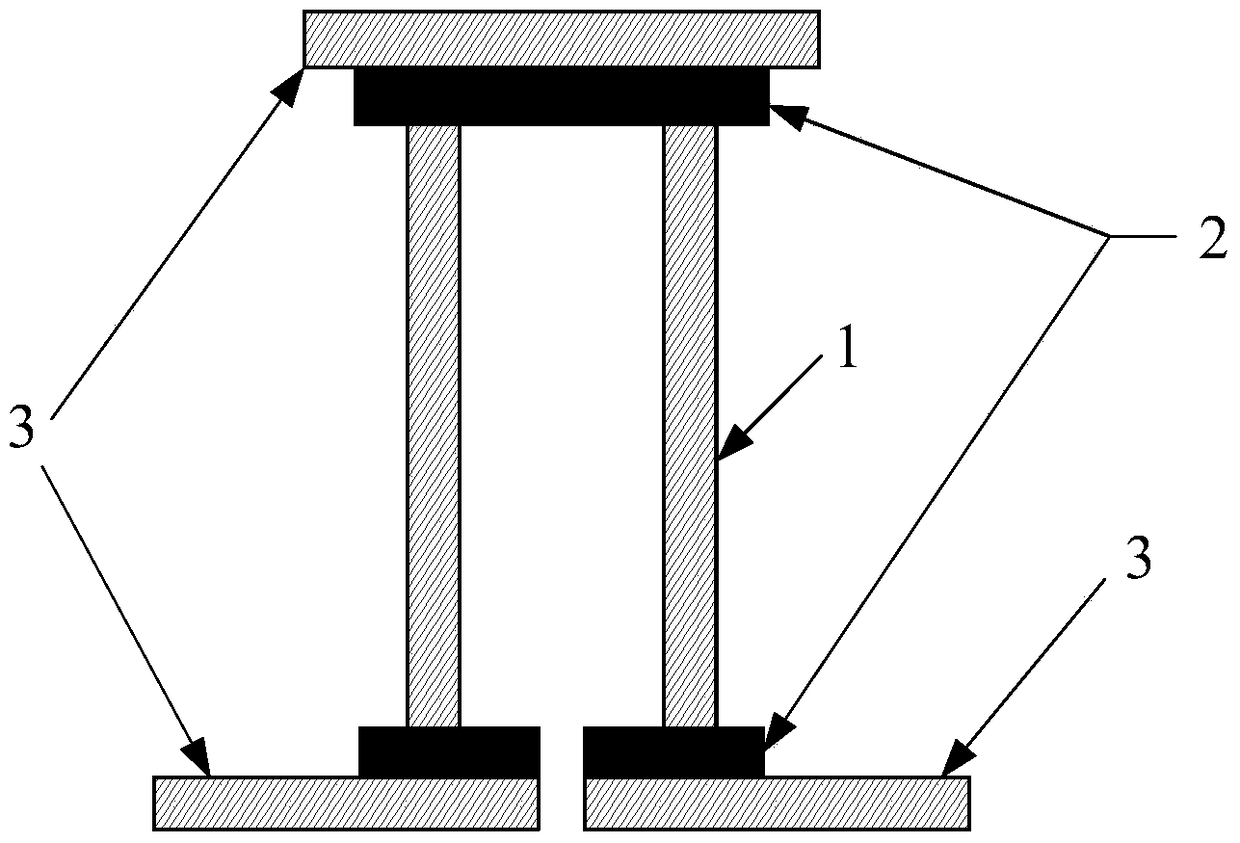

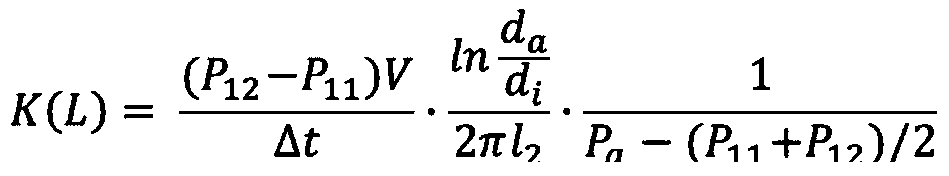

[0034] Such as figure 1 As shown in the illustration, connect and assemble the vacuum pump III, the first vacuum gauge IV, the second vacuum gauge V, the test gas chamber I, the test chamber II, the first pipeline VI, and the second pipeline VII, and connect the test sample 1 according to figure 2 The shown clamp is fixed in the vacuum chamber in the fixture, and the vacuum chamber is divided into two parts: the test gas chamber I and the test chamber II. Close the first vacuum breaking valve A and the second vacuum breaking valve D, open the first vacuum valve B and the second vacuum valve C, turn on the vacuum pump III to evacuate the test gas chamber I and the test chamber II; measure through the first vacuum gauge IV The vacuum degree of the test chamber II is measured by the second vacuum gauge V to measure the vacuum degree of the test gas chamber I; when the vacuum degree of both reaches the background vacuum degree, such as <100Pa, close the first vacuum valve B and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com