A new structure cleaning tank

A new structure, cleaning tank technology, applied in the field of cleaning tanks, new structure cleaning tanks, can solve the problems of large water volume and unsatisfactory cleaning effect, achieve the effect of less water consumption, ideal cleaning effect, and overcome large water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

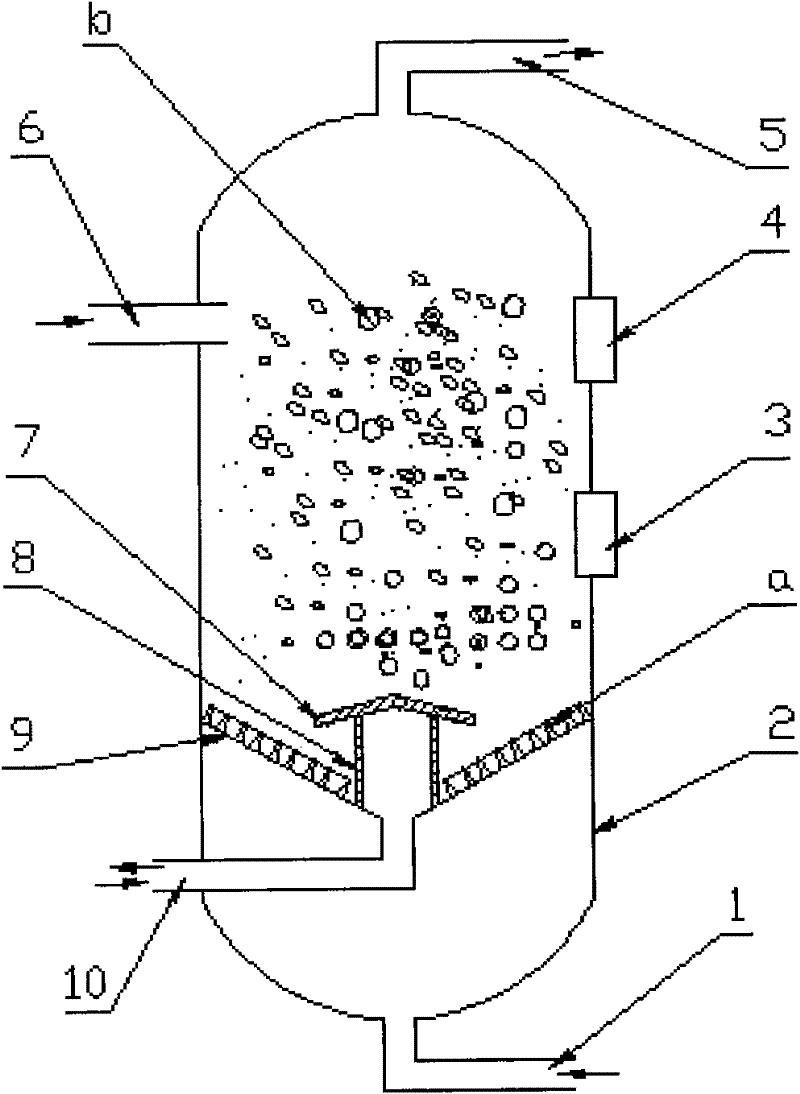

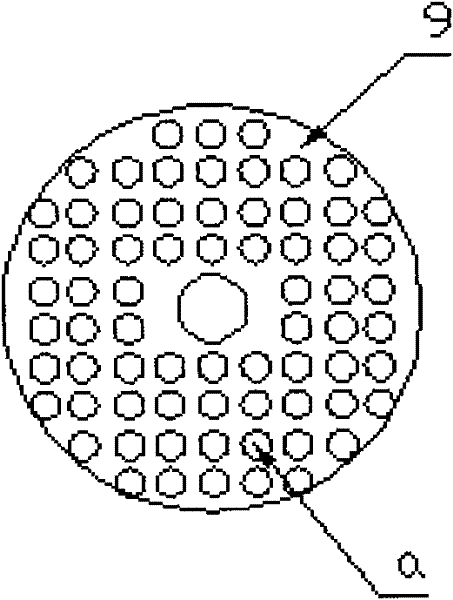

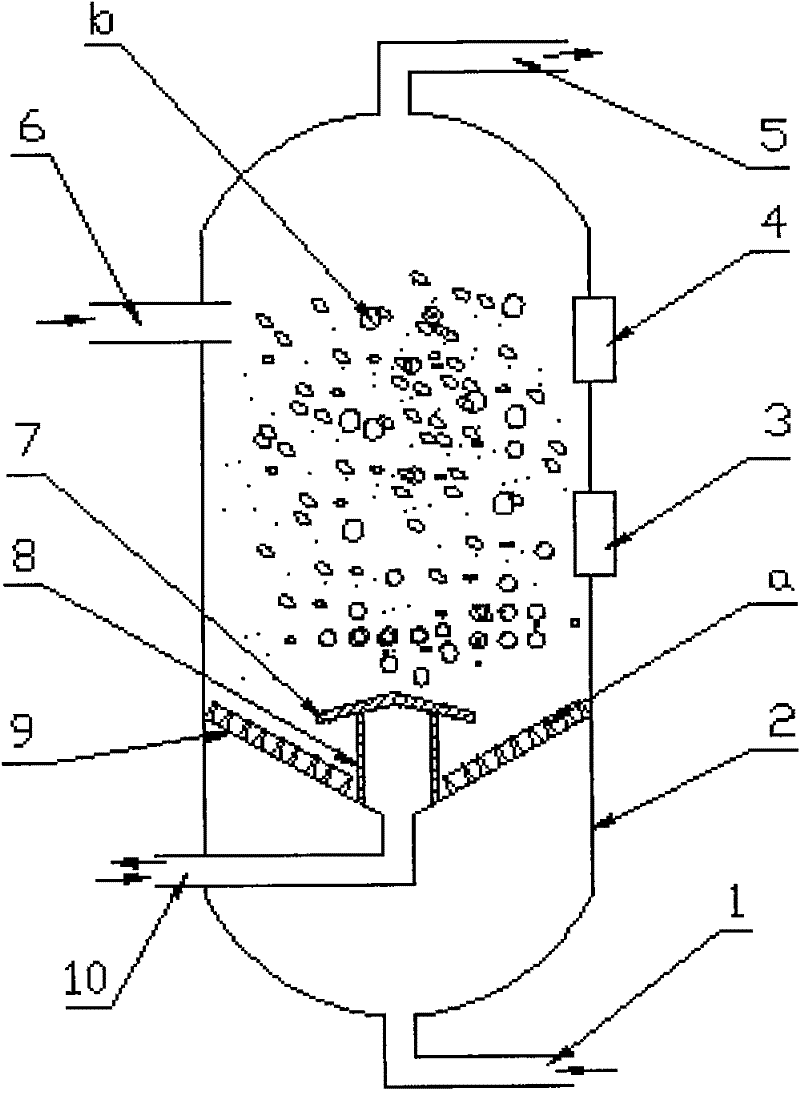

[0012] The cleaning tank has a conical cleaning plate (9), densely covered with through holes (a) on the conical cleaning plate (9), the diameter of the through hole (a) is less than the diameter of the normal resin (b), and the conical cleaning plate (9) ) is installed at the lower part of the tank body (2), the conical part of the conical cleaning plate (9) faces downward, and the conical part of the conical water retaining cap (7) is installed upwards on the Directly above the conical cleaning plate (9), the normal resin return pipe (10) is communicated with the middle hole of the conical cleaning plate (9) through the lower part of the tank body (2), and the high-pressure water inlet pipe (1) is installed on the The lowest part of the tank body (2), the lower observation mirror (3) and the upper observation mirror (4) are respectively installed on the upper and lower positions of the side wall of the tank body (2) on the upper part of the conical cleaning plate (9) to crush...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap