A method for installing a guide wire

A technology of pilot rope and installation system, which is applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., which can solve the problems of large traffic impact, high energy consumption, and high cost, and achieve the goal of reducing impact, low energy consumption, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

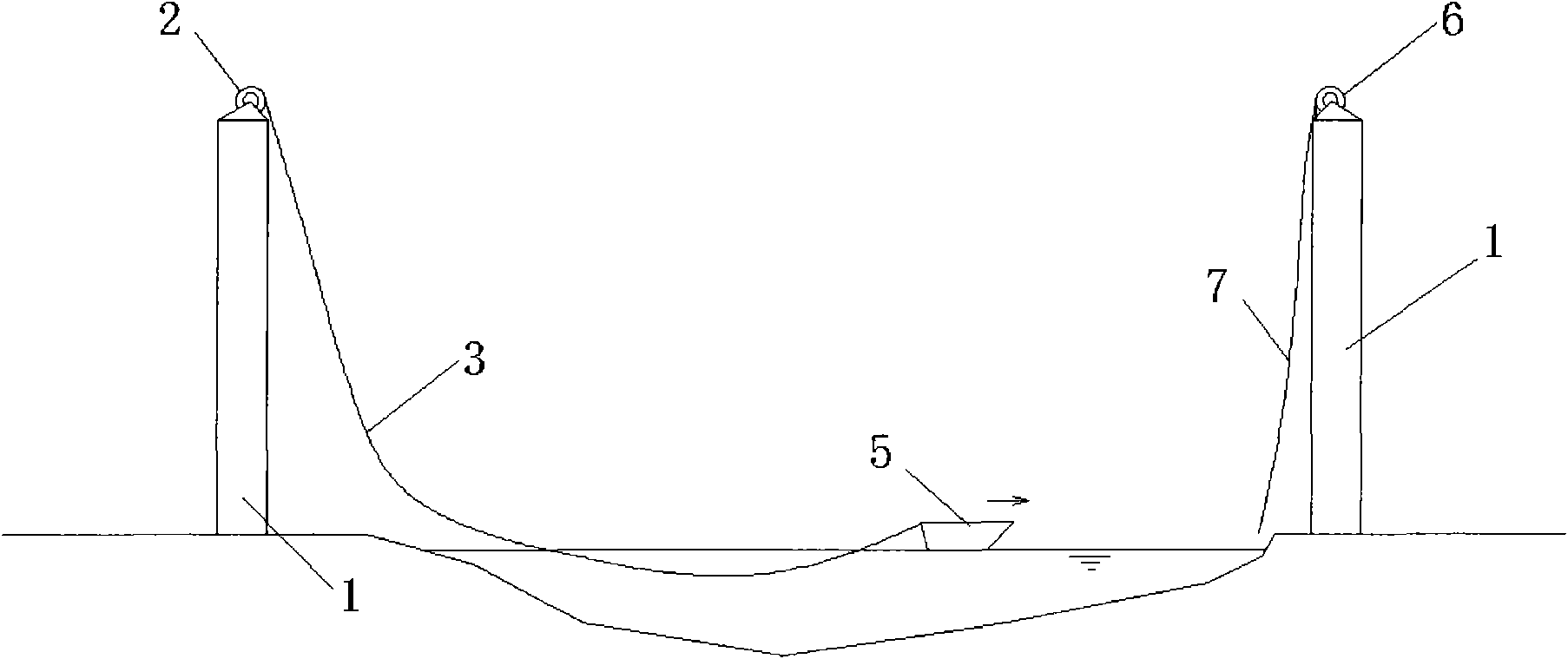

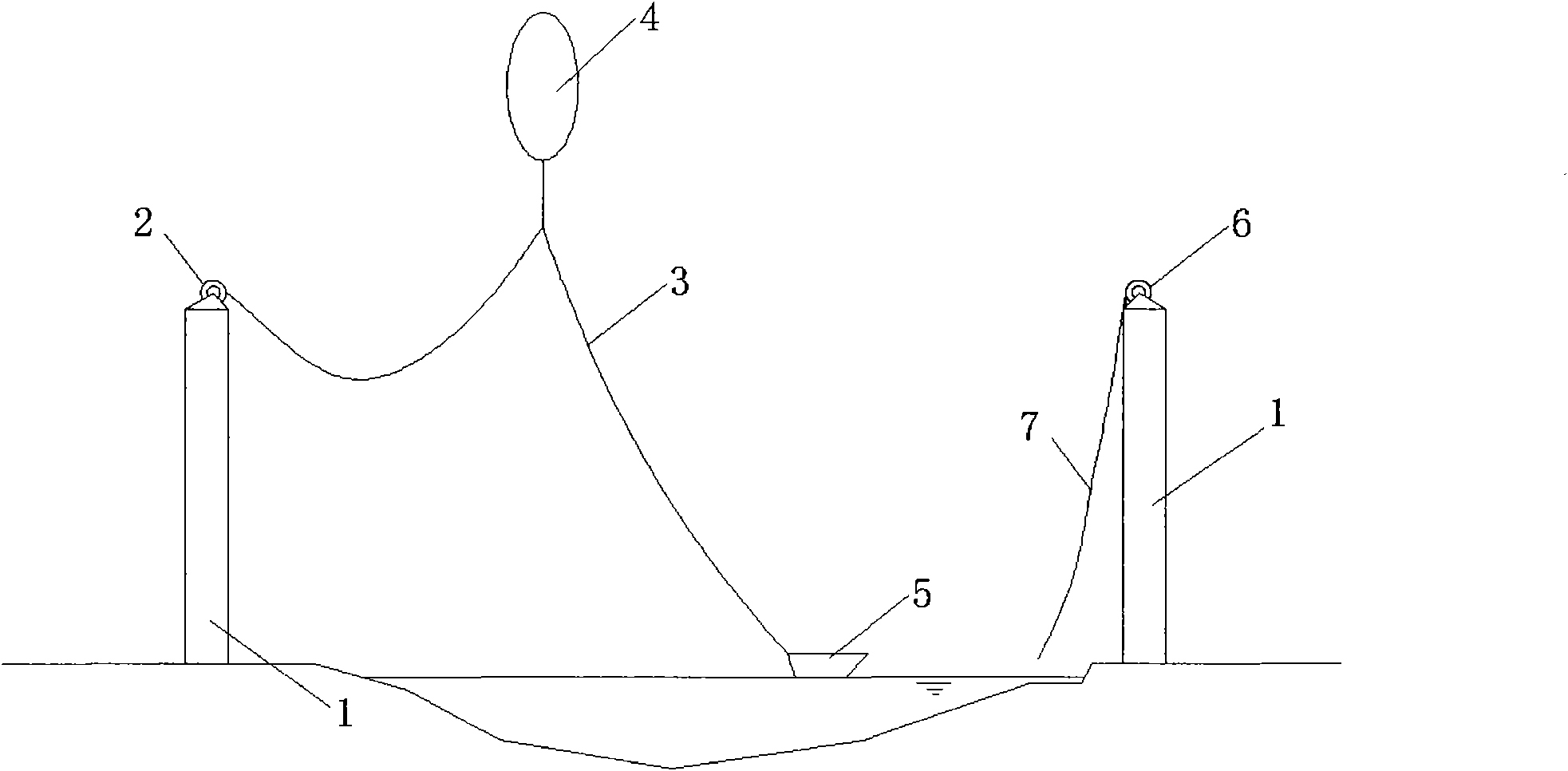

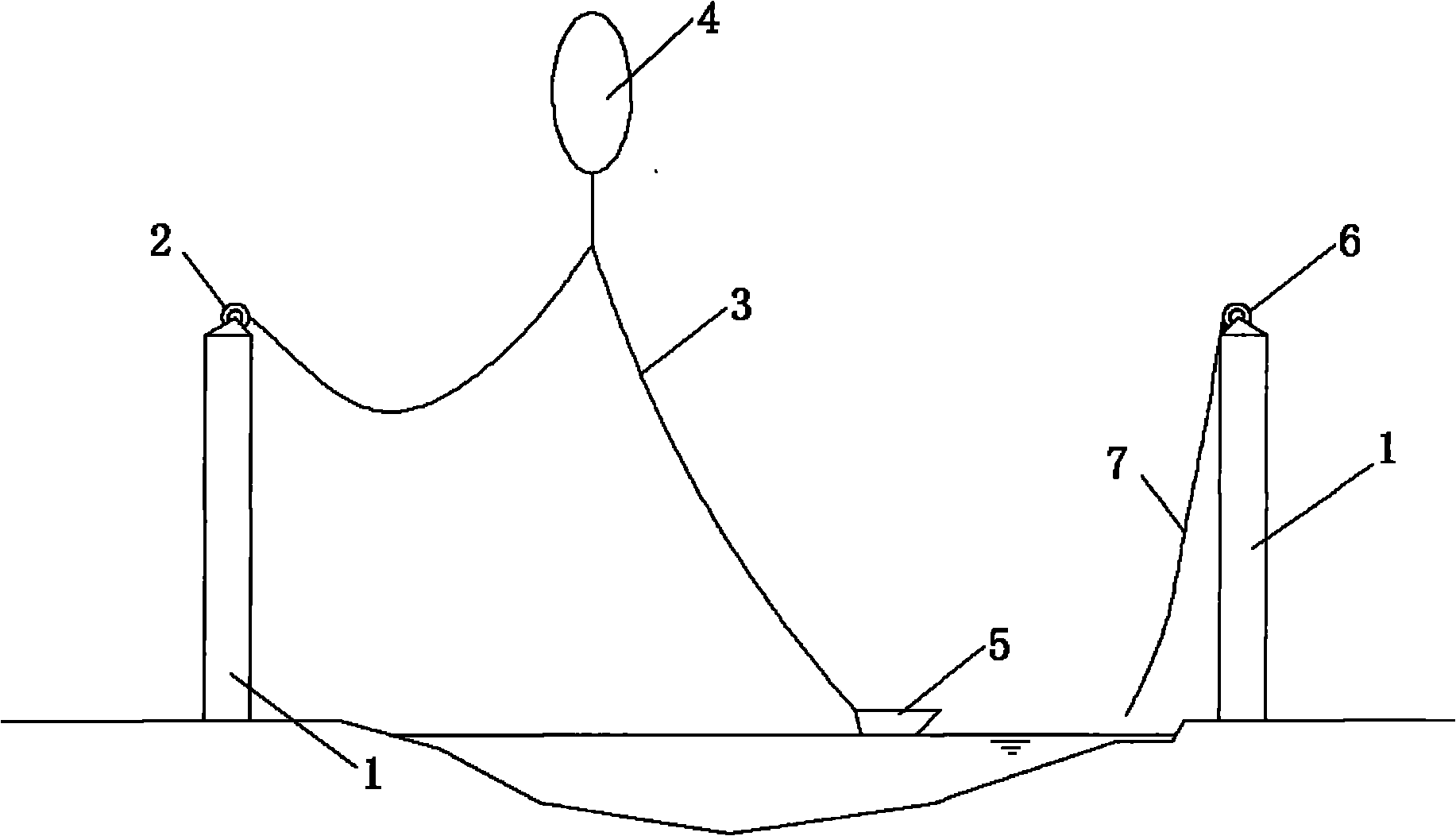

[0029] like figure 1 As shown, the pilot cable installation system of the present invention is composed of a cable release device (2), a pilot cable (3), a balloon (4), a ship (5), a cable retractor (6) and a transition cable (7). Composition, the cable release device (2) is fixed on the top of the A bridge tower (1), the rear end of the pilot cable (3) is fixed, and the front end is drawn out and connected with the ship (5) after passing through the cable release device (2), and the ship (5) ) and the cable release device (2), the length of the pilot cable is greater than the height of the bridge tower; there is a balloon (4) on the pilot cable (3), and the balloon (4) is used to lift the pilot cable (3) to a height that does not affect traffic; The cable receiving device (6) fixed on the top of another bridge tower B is connected to the rear end of the transition cable (7), and the front end of the transition cable (7) is placed under the bridge tower B; the ship (5) can tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com