Segmental accumulative jacking installation method of vase-shaped space steel structure

An installation method and technology of steel structure, applied in the direction of building structure, construction, etc., can solve the problems of increased cost of construction measures, increased support materials and labor, prolonged construction period, etc., to reduce difficulty, reduce the number of adjustments, reduce The effect of the amount of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

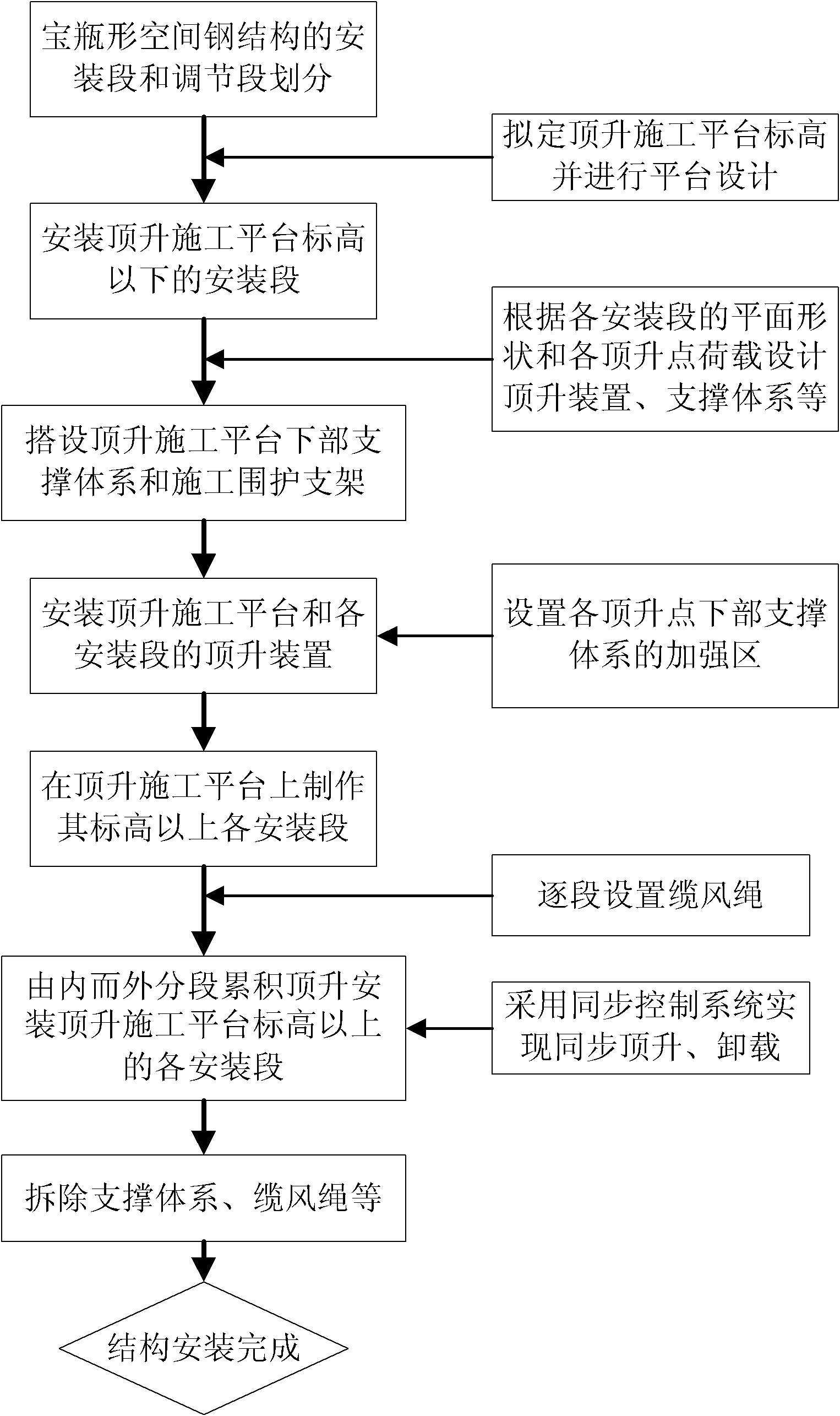

[0029] According to the structural characteristics of the vase-shaped space steel structure with large section size and large variation in section size along the height direction, the invention adopts the construction method of section production and cumulative jacking installation to realize the high-altitude non-crane auxiliary installation of the structure. The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

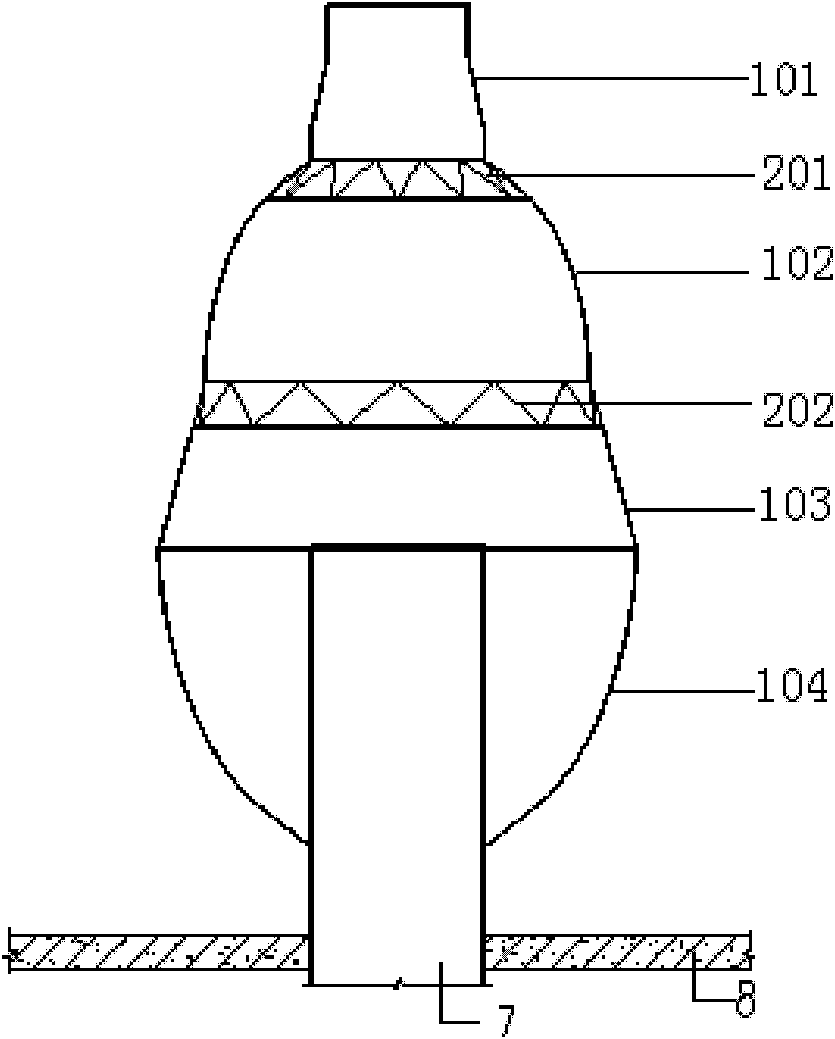

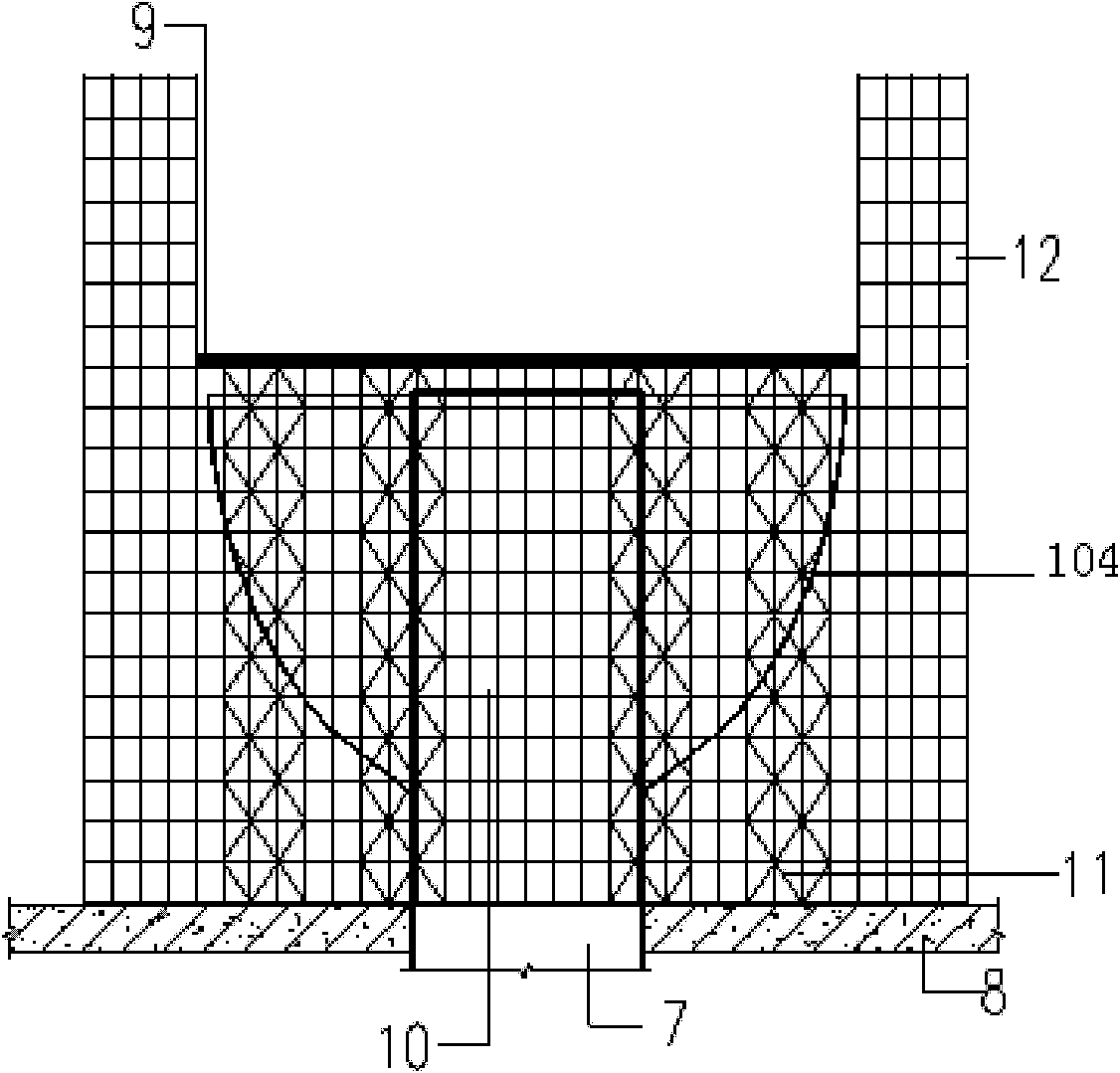

[0030] figure 1 It is a schematic diagram of division of the facade of the vase-shaped space steel structure installation section and the adjustment section of the present invention, figure 2 It is the operation flowchart of the segmental accumulative jacking installation method of the vase-shaped space steel structure of the present invention, Figure 3a It is the schematic diagram of the installation of the installation section below the elevation of the jacking construction platform, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com